You might ask, what is the working principle of laser cleaning? In simple words, it uses strong light to break and remove things you do not want on a surface. The working principle of laser cleaning ensures that it does not touch or hurt the main material. This method can clean over 90% of dirt, which is better than many old ways of cleaning. The use of this technology is growing around the world:

- The global laser cleaning market may reach US$780 million in 2025.

- By 2030, it could grow to US$1.02 billion.

- The yearly growth rate is about 5.51%.

You can see how this new way helps you clean things safely and effectively, and you do not need to know hard words to understand it.

Key Takeaways

- Laser cleaning uses strong light to take off dirt. It does not touch the surface, so it keeps the main material safe.

- This method can clean more than 90% of dirt. It works better than old cleaning ways.

- Laser cleaning works in three main steps: thermal ablation, thermal stress, and plasma shock waves.

- Pulsed lasers are best for gentle surfaces. They give more control and lower heat damage.

- Laser cleaning is good for the environment. It does not need chemicals or water, so it makes less harmful waste.

- The technology saves money because it cuts labor and material costs over time.

- Laser cleaning is used in many fields, like cars, planes, and art care. It is chosen for its accuracy and speed.

- Always use safety rules when using laser cleaning tools. This keeps you and others safe.

The Working Principle of Laser Cleaning

How Laser Cleaning Works

Light Energy and Contaminant Removal

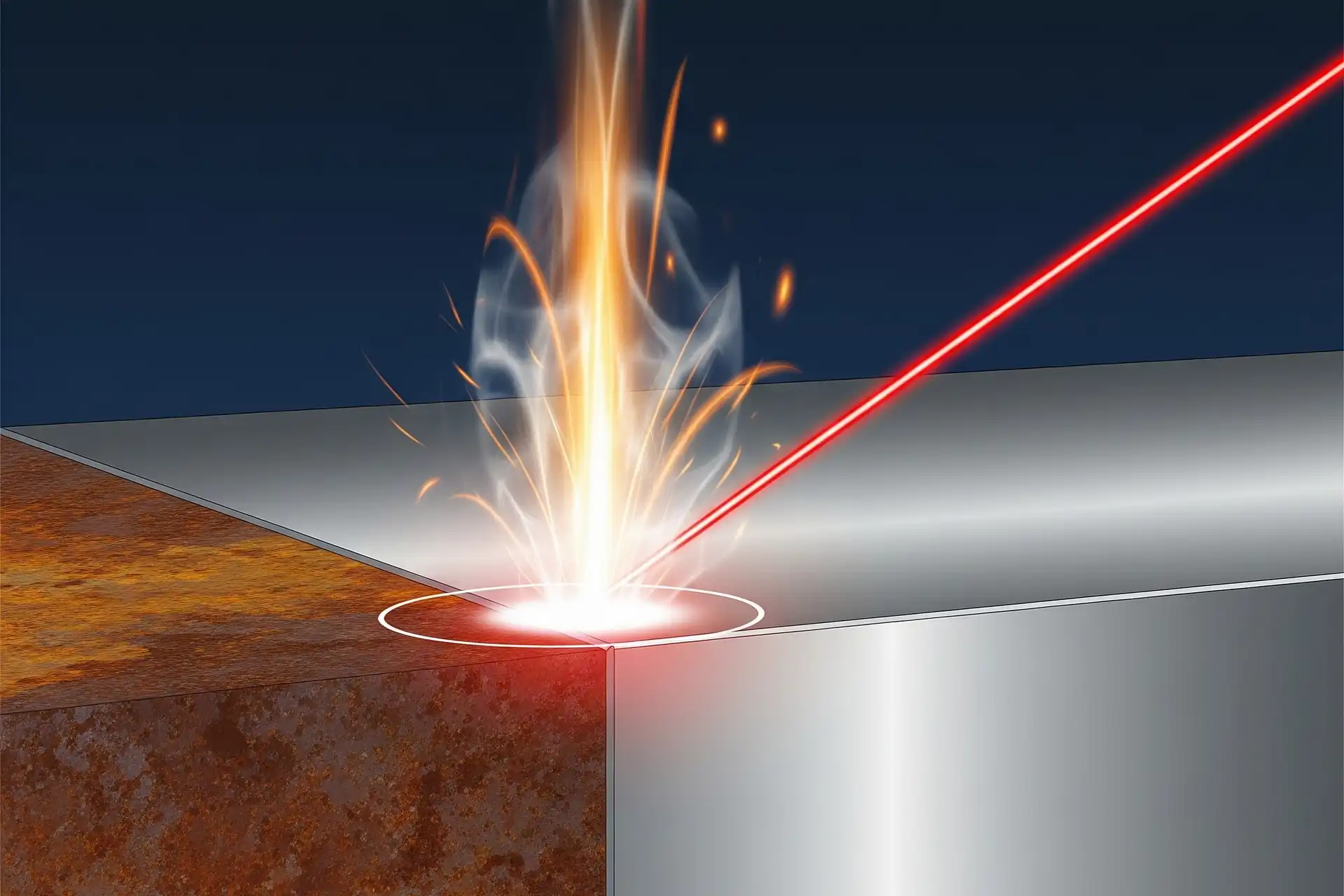

Laser cleaning is like using a super strong flashlight. The working principle of laser cleaning starts when a laser beam shines on a dirty spot. This beam has a lot of energy in one small place. When the light hits the dirt, it gets hot very fast. The heat makes the dirt or rust turn into gas or tiny bits. These bits leave the surface. This is called ablation.

Tip: Laser cleaning works best if you use the right energy for the dirt and the surface.

Scientists found three main ways laser cleaning removes dirt:

- Laser thermal ablation: The laser heats the dirt so much it turns into vapor.

- Laser thermal stress: The laser makes the dirt crack and break off.

- Plasma shock wave: The laser makes a tiny plasma cloud that pushes dirt away, especially small pieces.

These ways work together to clean without chemicals or brushes.

Pulse-by-Pulse Cleaning Process

Laser cleaning does not use a steady light. It sends out quick flashes called pulses. Each pulse lasts just a few billionths of a second. These short pulses give enough energy to take off a thin layer of dirt. The main material under the dirt does not get too hot. You can change the number and strength of the pulses for each job.

Here is a table that shows power levels and what they clean best:

| Power Level | Application Type | Description |

|---|---|---|

| 20-100W | Light Cleaning | Takes off paint or oxidation, good for gentle surfaces. |

| 100-500W | Medium-Duty | Removes rust and cleans molds, goes deeper. |

| >500W | Heavy-Duty | Cleans big rust spots and thick coatings, very fast. |

Studies show nanosecond laser pulses can remove over 90% of tiny dirt from surfaces. This makes laser cleaning technology great for small and big jobs.

Non-Destructive Laser Cleaning

Protecting the Base Material

A great thing about the working principle of laser cleaning is it keeps the main material safe. You do not have to worry about scratches or damage. You can change the laser’s energy and speed to clean only the dirt. Advanced systems let you aim the laser very carefully, even on tricky shapes.

Researchers found ways to protect the base material:

- You can adjust the energy and how often the laser fires to clean well but not hurt the surface.

- Some ways use shockwaves or plasma to lift dirt without much heat, so the material stays cool.

- When plasma forms, it can block extra laser energy, so you do not over-clean.

- Short pulses keep heat from spreading, so only the dirt gets hot.

A study on cleaning aluminum alloys showed laser surface cleaning can take off coatings without hurting the metal. The process uses ablation, vaporization, and plasma shock to keep the surface safe.

No Physical Contact

Laser cleaning is special because it never touches the surface. You do not need brushes, sand, or chemicals. The laser beam does all the work from far away. This means you do not get scratches, dents, or leftover cleaning stuff. The work area also stays cleaner and safer.

Here is a quick look at how different materials react to non-destructive laser cleaning:

| Material Type | Laser Type | Effectiveness | Challenges |

|---|---|---|---|

| Archaeological Iron | N/A | Thick crusts removed, some heat effects | Not always self-limited, some heat side effects |

| Archaeological Silver | Nd:YAG | Removes corrosion well | Some side effects |

| Lead | Nd:YAG | Not good for corrosion | N/A |

| Zinc | Nd:YAG | Not good for corrosion | N/A |

| Archaeological Copper | N/A | Not cleaned well | N/A |

You can see laser cleaning works best on some materials, but not all. The working principle of laser cleaning helps you pick the right settings for each job.

Note: Laser cleaning started in the 1970s. Over time, experts made the process safer and better for many industries.

The working principle of laser cleaning lets you remove dirt safely, quickly, and without touching the surface. You get a clean result and keep your important materials safe at the same time.

Laser Ablation Explained

Laser ablation is a key part of laser cleaning. You use this to take off layers you do not want. The laser beam sends out short, strong bursts of energy. This energy hits the dirt or coating and breaks it up. The unwanted layer comes off, leaving the surface clean.

Photonic Energy Interaction

When you shine a laser on dirt, you send photons to it. Photons are tiny bits of light that carry energy. The dirt or coating soaks up this energy very fast. The spot gets hot in a short time. The temperature rises quickly in that small area.

Vaporization and Sublimation

When the laser energy hits the dirt, two things can happen:

- Vaporization: The dirt gets so hot it turns into gas. You might see a small cloud above the spot.

- Sublimation: Some solids skip melting and turn right into gas. This happens with some kinds of dirt or coatings.

Note: You do not need water or chemicals. The laser uses only light and heat to clean.

The laser works best when you match its settings to the dirt. Rust and paint come off well with certain laser choices. You can change the power and pulse time for the best cleaning.

Breaking Molecular Bonds

The real work of laser ablation happens in the molecules. The laser breaks the bonds that hold the dirt together. The photons make the atoms in the dirt move faster. This gives them enough energy to break apart.

Ejection of Impurities

After the bonds break, the dirt cannot stay on the surface. The laser pulse pushes the broken pieces away. You see these as tiny bits or gas leaving the spot.

Scientists have studied how lasers break these bonds. For example, UV laser energy can break C–H bonds in plastics like HDPE. The UV photons make hydrogen atoms move and snap the bonds. This works best when you use just the right energy. Too much energy can hurt the main material, so you must pick the right settings.

Here is a simple table to show what happens during laser ablation:

| Step | What Happens | Result |

|---|---|---|

| Laser hits surface | Photons give energy | Surface gets hot |

| Bonds break | Atoms move and split up | Dirt breaks into small bits |

| Ejection | Broken bits leave the surface | Clean, bare material remains |

Tip: You can control how much you clean by changing the laser’s power and pulse. This lets you clean gently or take off thick layers.

Laser ablation is a strong and careful way to clean. You use light, not force, to remove unwanted layers. This keeps your main material safe and makes cleaning quick and easy.

Types of Lasers Used

Pulsed vs. Continuous Lasers

Laser cleaning systems use two main types of lasers. These are pulsed lasers and continuous lasers. It is important to know how each type works. This helps you pick the best one for your job. Pulsed lasers send out quick bursts of energy. Continuous lasers shine a steady beam of light. Each type has good and bad points.

Why Pulsed Lasers Are Preferred

Pulsed lasers are common in laser cleaning systems. They give you more control over the cleaning process. Pulsed lasers work by sending fast flashes of light. Each flash lasts only a tiny moment. This lets you take off dirt or coatings one layer at a time. You can clean soft surfaces without hurting them.

Continuous lasers are faster for big areas. But they can make the material too hot. This can damage things that are easy to harm. Pulsed lasers keep the heat low. This helps protect the main material. You get better results when you need to be careful.

Here is a table that shows how pulsed lasers and continuous lasers are different:

| Feature | Continuous Lasers | Pulsed Lasers |

|---|---|---|

| Cleaning Efficiency | Good for big jobs, works quickly | Very precise, but slower |

| Safety | Can cause heat damage to soft materials | Safer for delicate things, less heat |

| Surface Quality | Not good for things that heat up easily | Works well on soft surfaces, removes little material |

Tip: Use pulsed lasers for fragile things. Use continuous lasers for tough, large surfaces.

You can see pulsed lasers work best for soft surfaces and careful cleaning. Continuous lasers are better for big, tough jobs that need steady power.

Common Laser Sources

Laser cleaning systems use different laser sources for different jobs. You need to choose the right one for your task. Here is a table that shows the most common types and what they are good for:

| Laser Type | Advantages | Applications |

|---|---|---|

| Pulse Laser | Sends strong bursts for careful cleaning. Makes little heat, good for soft materials. | Used for taking off coatings and oxide layers. Good for restoring old things. |

| Continuous Wave (CW) | Shines all the time for fast, big jobs. Cleans quickly and costs less. | Used for removing rust and thick coatings. Good for cleaning in factories. |

Pulse lasers are used for restoring things and cleaning thin layers. They help you avoid damage to special or soft items. Continuous wave lasers are good for taking off rust or thick layers from big metal parts.

Laser cleaning systems use these sources to fit the job. You get the best results when you pick the right laser. If you want to clean an old statue, use pulsed lasers. If you need to clean a big steel beam, continuous lasers are better.

You can change laser cleaning systems to work on many surfaces and materials. This makes them helpful in factories, museums, and workshops.

Laser cleaning systems are flexible and safe. You can clean with care or cover big areas fast. Pulsed lasers help you protect soft surfaces. Continuous lasers help you finish big jobs quickly.

Benefits of Laser Cleaning

Precision and Selectivity

Laser cleaning gives you very exact results. The laser only removes the unwanted layer. It does not hurt the base material. This is great for taking off paint or cleaning gentle surfaces. You can change the laser to fit the kind of dirt or coating. This helps you clean hard-to-reach or bumpy spots, like places with marine growth or rust.

- Laser cleaning keeps the material safe and works with high accuracy.

- You can clean rough dirt, like marine microorganisms, without harming metal.

- Laser cleaning uses photon pressure, thermal ablation, and plasma bursts to clean surfaces well.

If you need to clean both strong and soft spots, laser cleaning lets you control the process. You can trust it for careful jobs, like removing paint or coatings, and keeping the original surface safe.

Safety and Eco-Friendliness

Laser cleaning is good for the environment. You do not need strong chemicals or water. This helps protect nature. It also makes your workspace safer. You do not get toxic fumes or dangerous waste.

- Laser cleaning removes harmful chemicals, so surfaces are easier to recycle and helps the planet.

- You use no water, which is helpful where water is hard to find.

- The process turns dirt into gas, so there is no leftover mess.

- You stop soil, air, and water pollution, which matters for sensitive places.

Tip: Always handle the fine powders and gases from laser cleaning the right way to keep the air safe.

Laser cleaning is easy to use with machines. You can use it in many fields, like aerospace and car making, where safety and caring for the earth are important. This makes laser cleaning a top pick for companies that want to help the environment.

Cost-Effectiveness

Laser cleaning helps you save money over time. The machines can cost the same as old cleaning ways. But you spend less on workers, safety gear, and fixing things. You do not buy chemicals or deal with messy waste, so your costs stay low.

| Aspect | Traditional Methods | Laser Cleaning |

|---|---|---|

| Equipment Costs | Sandblasting: $25,000–$500,000; Chemical: $50,000-$100,000 | $35,000–$500,000 |

| Labor and Safety Costs | Many workers needed; expensive safety gear | One technician; no chemicals |

| Maintenance and Downtime | Lots of clogging; costly waste removal | Little wear; easy to fix |

| Operating Costs Over Time | Ongoing media/chemical costs; higher utility | Only electricity; no extra supplies |

| Eco-Friendly | Makes waste and dust | No runoff; follows rules |

You can run laser cleaning with just one person. You also avoid lots of breakdowns and costly waste removal. Over time, you save more money, so laser cleaning is a smart choice for many companies. You get strong cleaning, lower costs, and a safer, cleaner place to work.

Applications of Laser Cleaning

Industrial Uses

Laser cleaning is used in many industries now. It helps keep machines and surfaces clean. You do not need strong chemicals for this method. It is good for taking off unwanted layers fast and safely. Here are some ways people use laser cleaning:

- Takes rust off metal parts

- Removes oxide before painting or bonding

- Takes paint and coatings off machines or cars

- Cleans welds to make them strong and smooth

- Cleans molds in factories to keep products safe

- Cleans tools so they last longer

- Gets surfaces ready for glue

Many industries use laser cleaning. These include:

- Car making

- Airplane building

- Factories

- Saving old art and history

- Ship making

Laser cleaning helps solve many cleaning problems. It works quickly and keeps equipment working well.

Conservation and Restoration

Laser cleaning helps protect and fix old art and historic things. You can take off dirt and old coatings without hurting the real surface. Experts use it to clean statues, paintings, and buildings. Here are some examples:

| Case Study | Description |

|---|---|

| Romanesque Polychrome Sculptures | Scientists used lasers to clean sculptures in Italy. The colors and surfaces stayed safe. |

| National Trust Conservation Studio | Experts made a gentle laser to clean dark layers off old surfaces. This showed the real artwork underneath. |

Laser cleaning helps keep history safe. For example, Salimbeni and others showed you can clean old sculptures without damage. The National Trust uses lasers to restore old decorations without strong chemicals.

Tip: Laser cleaning is great for delicate surfaces. It helps you avoid damage.

Electronics and Microfabrication

Laser cleaning is used in electronics to keep tiny parts clean. Even small dirt can cause problems in electronics. Laser cleaning takes off flux, fingerprints, and tiny bits from sensitive places. It does not touch the parts, so nothing gets damaged.

| Application Area | Benefits |

|---|---|

| Semiconductor wafer processing | Makes surfaces very clean for making microchips. |

| Microchip fabrication | Keeps dirt away in places that need to be super clean. |

| Printed circuit boards (PCBs) | Cleans without using water or chemicals. |

| Optics and photonics | Uses quick lasers to stop heat damage on small parts. |

Laser cleaning removes dirt from PCBs and wafers. It does not make static or stress. You get very exact cleaning and can even take off insulation from thin wires. Laser cleaning helps electronics work better and last longer.

Limitations and Considerations

When Laser Cleaning May Not Be Suitable

Laser cleaning does not work for every job. Some surfaces and dirt can be hard to clean. Here are some problems you might see:

- Laser beams cannot reach deep holes or tiny cracks. Dirt can stay in these places.

- Thick or sticky stuff, like heavy oil or tar, is hard to remove.

- Soft, weak, or shiny surfaces may not soak up the laser energy. This makes cleaning less strong.

- The laser’s heat can cause burns, color changes, or small changes inside the material.

- Shapes with grooves or 3D bumps are hard to clean all over.

- Do not use laser cleaning near things that can catch fire or explode. The laser could start a fire or cause an explosion.

Tip: Always test a small spot first to see if laser cleaning works for your material.

Safety Precautions

Laser cleaning uses very strong light. You must follow safety rules to keep everyone safe. Many places have laws for using these machines. The table below shows important safety rules:

| Category | Details |

|---|---|

| Overview of Equipment | Class 3b and 4 lasers can hurt you badly. You must register them and put up warning signs. |

| Potential Hazards | The beam can hurt your eyes or skin. High voltage can shock you. |

| Personal Protective Equipment | Wear laser safety glasses and have fire extinguishers nearby. |

| Engineering Controls | Turn off power, use safety locks, and clear away flammable things. |

| Work Practices | Write and post a laser safety plan for Class 4 lasers. |

| ANSI Standards | Follow Z136 rules for safe laser use. |

| FDA Regulations | Meet 21 CFR Part 1040 rules for laser products. |

| NFPA Standards | Use NFPA 115 for fire safety with lasers. |

| IEC Standards | Follow IEC rules for laser safety in different jobs. |

| ISO Guidelines | Make sure you have good air flow and exhaust systems. |

| Key Safety Requirements | Pick a Laser Safety Officer, control the area, train workers, and check safety often. |

Note: Never look at the laser beam. Always wear the right safety gear.

Equipment and Cost

Think about the price before you buy a laser cleaning machine. The cost depends on the power and type you pick. Small machines start at about $5,000. Big, strong machines can cost over $200,000. You will pay for electricity, but you do not need chemicals or sand. This makes running costs lower than old cleaning ways.

| Cost Category | Price Range |

|---|---|

| Low-power models (20W–100W) | $5,000 – $20,000 |

| Medium-power models (100W–500W) | $20,000 – $60,000 |

| High-power industrial models (500W–2000W+) | $60,000 – $200,000+ |

You should also plan for:

- Regular checks and simple repairs

- Replacing parts like lenses and nozzles

- Worker training, which may cost $500 to $2,000 for special lessons

Tip: Even though the first price is high, you may save money later because you do not need many workers or supplies.

Laser cleaning has many good points, but you must think about these limits, safety steps, and costs before you choose if it is best for you.

Future of Laser Cleaning

Advances in Technology

Laser cleaning is changing fast. Engineers made handheld systems for more control. These tools clean surfaces 30% faster than before. You can use mobile devices to change settings from far away. This helps you work easier in factories and on big machines.

Many companies use eco-friendly systems now. These systems do not make chemical waste. This helps protect the environment. Automation is better too. Machines can change their cleaning power by themselves. You get a clean surface and do not worry about damage. These new ideas make laser cleaning safer and quicker.

Here are some new improvements:

- Handheld systems give better control and clean faster

- You can use mobile devices to control cleaning easily

- Eco-friendly designs help cut down on waste

- Automated controls change settings for each job

Tip: New technology helps you clean more surfaces with less work.

Expanding Applications

Laser cleaning is used in more places each year. Many industries use it for different jobs. In factories, you can clean molds and tools fast. You can also get surfaces ready for painting or gluing. Car and airplane makers use laser cleaning to keep parts clean.

Museums and art experts use laser cleaning to fix old things. You can take dirt off statues and paintings without hurting them. Weld cleaning is also growing. You can clean welds to make them stronger and safer.

Some new uses for laser cleaning are:

- Cleaning molds in factories

- Cleaning tools so they last longer

- Getting surfaces ready for paint or glue

- Cleaning in car and airplane factories

- Saving and fixing old things in museums

- Cleaning welds for safer joints

You will see more uses as technology gets better. Laser cleaning is a safe and strong way to keep things clean in many jobs.

Laser cleaning uses strong laser flashes to take off dirt and coatings. This way, you clean things quickly and safely without using chemicals. New studies show some important facts:

- You finish cleaning faster and spend less money.

- You only remove what you do not want, so the surface stays safe.

- You protect nature because there is no dangerous waste.

You can use laser cleaning to get rid of rust, oxides, or to get things ready. If you want to know more about how it works or what you can clean, just ask in the comments!

FAQ

What surfaces can you clean with a laser?

You can clean metals, stone, glass, and some plastics. Laser cleaning works best on hard surfaces. Soft or shiny materials may not clean well. Always test a small area first.

Is laser cleaning safe for the environment?

Yes! Laser cleaning does not use chemicals or water. You do not create toxic waste. You help protect the environment by using only light energy.

Will laser cleaning damage my material?

You control the laser’s power and speed. This lets you remove dirt without harming the base material. You keep your items safe and clean.

How fast does laser cleaning work?

Laser cleaning works quickly. You can clean small spots in seconds. Large areas may take longer. The speed depends on the laser’s power and the type of dirt.

Do you need special training to use a laser cleaner?

Yes. You should learn how to use the machine safely. Training helps you avoid accidents and get the best results. Many companies offer short courses.

Can you use laser cleaning indoors?

You can use laser cleaning indoors. Make sure you have good ventilation. Some dirt turns into gas or dust. Use safety gear and follow local rules.

How much does a laser cleaning machine cost?

Prices range from $5,000 for small units to over $200,000 for big machines. You save money over time because you do not buy chemicals or pay for waste removal.

What safety gear do you need for laser cleaning?

Always wear laser safety glasses. Use gloves and cover your skin. Keep a fire extinguisher nearby. Follow all safety rules for your workplace.

See also

How to set laser parameters for optimal cleaning effect

Common problems and solutions in the use of laser cleaning machines

Choosing Wavelength and Spot Size for Laser Cleaning

How to Use a Customized Laser Cleaning Solution for Better Results