A laser cleaning machine utilizes strong laser light to clean surfaces effectively. It removes rust, paint, or dirt without direct contact. Understanding the laser cleaning machine components is essential for safe operation and maintenance. This knowledge helps you take care of your machine properly. The laser’s non-contact method ensures that fragile surfaces remain unharmed. Many businesses choose laser cleaning machine systems for their environmental benefits. The table below outlines the primary reasons:

| Environmental Benefit | Description |

|---|---|

| Eliminates Hazardous Chemicals | No solvents or acids are used, avoiding toxic fumes and residues. |

| Zero Water Consumption | No water is required, conserving resources and preventing wastewater issues. |

| No Abrasive or Residual Waste | No sand or grit is produced; dirt is converted into vapor. |

| Energy-Efficient Operation | These machines consume less energy and generate minimal pollution. |

| Reduced Environmental Contamination | No chemical runoff to contaminate soil, air, or water. |

| Longer Equipment Lifespan | The gentle cleaning process contributes to a longer lifespan for machines. |

Key Takeaways

- Laser cleaning machines use strong lasers to clean surfaces. They do not touch the surface, so they are safe for fragile materials.

- These machines help the environment in big ways. They do not use dangerous chemicals. They also save water.

- It is important to know the parts of a laser cleaning machine. This helps you use it safely and keep it working well.

- Laser cleaning works in many different jobs. It is used in car making, airplane building, and food factories.

- Safety is very important. Always wear safety gear. Make sure there are no things that can catch fire in the workspace.

- You should take care of the machine often. Clean the optics and check the cooling systems. This helps the machine last longer.

- Pick the right laser cleaning machine for your needs. Think about what material you need to clean and how dirty it is.

- Buying a good machine with strong support is smart. It can work better and cost less over time.

What Is a Laser Cleaning Machine?

Definition and Purpose

A laser cleaning machine is a tool that uses focused laser beams to clean surfaces. It can remove things like rust, paint, grease, or other dirt. The machine shines a strong laser on the surface. The laser’s energy breaks up and turns the dirt into vapor. This way, the machine does not touch the surface. So, it does not scratch or harm it.

Laser cleaning machines are important in many industries. The table below shows why companies use this technology:

| Purpose | Description |

|---|---|

| Remove contaminants | Laser cleaning takes away rust, oxides, paints, and other dirt from surfaces. |

| High precision | It lets you clean only certain spots without hurting nearby areas. |

| Non-damaging | This method does not add dirt or damage the main material, unlike rough cleaning. |

| Safety improvements | No dangerous chemicals are needed, so it is safer for workers. |

| Environmental benefits | It makes no waste, so there is less risk of pollution. |

| Cost-effective | It costs less to keep up because it does not use extra supplies. |

Laser cleaning machines are safe, accurate, and save money when cleaning surfaces.

Key Industrial Applications

Many industries use laser cleaning machines. Each one uses them for different cleaning jobs. The table below lists some common uses:

| Industry | Specific Applications |

|---|---|

| Automotive | Removes weld leftovers and mold release |

| Aerospace | Strips paint from airplanes |

| Electronics Manufacturing | Takes off chip and PCB coatings |

| Shipbuilding | Cleans rust and coatings from big metal parts |

| Food Processing | Gets rid of grease and dirt from machines |

| Precision Machinery | Cleans off oil and tiny dirt |

| Energy Equipment | Cleans power systems and pipes |

| Chemical Equipment | Removes leftover chemicals and buildup |

| Construction Materials | Restores tools and machines, removes graffiti |

Laser cleaning machines help with many cleaning problems. You can use them for small or big jobs. They work for cleaning thin layers on electronics or thick coatings on ships.

Environmental Benefits

Laser cleaning machines are better for the environment. You do not need water, chemicals, or rough materials. This means you do not make dangerous waste or pollution. The process turns dirt and coatings into safe vapor. Laser cleaning also uses less energy than old cleaning ways.

Tip: Using laser cleaning helps the environment and keeps workers safer.

Laser cleaning machines give you a new, green way to clean surfaces. You can trust this technology for fast and earth-friendly cleaning.

How Laser Cleaning Machines Work

Operating Principle

A laser cleaning machine works by shining a powerful laser beam onto a dirty surface. You can think of the laser as a very focused light that carries a lot of energy. When this energy hits the dirt or rust, it heats up the unwanted layer very quickly. The dirt absorbs the laser’s energy and starts to expand. If the force from this expansion gets strong enough, it breaks the bond between the dirt and the surface. The dirt then lifts off or turns into vapor.

Here is a table that shows the basic steps of how laser cleaning works:

| Aspect | Description |

|---|---|

| Interaction | The laser beam hits the dirt or coating on the surface. |

| Mechanism | The laser uses both physical and chemical processes to remove the dirt. |

| Energy Absorption | The dirt absorbs the laser’s energy and heats up fast. |

| Removal Process | The heated dirt expands and breaks away from the surface. |

| Pulse Characteristics | Short laser pulses keep the surface safe from too much heat. |

| Plasma Formation | Sometimes, the energy creates a small plasma cloud that helps push dirt away. |

| Cleaning Efficiency | You may need several pulses to clean thick or tough layers. |

Laser cleaning uses a mix of heat, pressure, and light to get rid of unwanted layers. This process does not harm the main material underneath.

Cleaning Mechanisms

Laser cleaning uses three main methods to remove dirt and coatings:

Thermal Ablation

Thermal ablation happens when the laser heats the dirt so much that it turns into gas. The heat is so intense that the dirt or paint just disappears. You can use this method for thin layers or light coatings. It works best when you want to avoid scratching the surface.

Thermal Stress

Thermal stress uses quick heating and cooling to make the dirt crack or break apart. The laser heats the dirt fast, and then it cools down quickly. This sudden change causes the dirt to pop off the surface. You often see this method used for rust or thicker coatings.

Plasma Shock

Plasma shock is a powerful cleaning method. When the laser hits the dirt, it creates a tiny, hot plasma cloud. This cloud expands very fast and sends a shock wave through the dirt. The shock wave blasts the dirt away from the surface. Plasma shock works well for tough jobs, like removing heavy rust or thick paint.

Here are the main cleaning methods in a simple list:

- Laser thermal ablation

- Laser thermal stress

- Plasma shock wave

Safety Considerations

Laser cleaning machines use strong lasers, so safety is very important. You need to protect your eyes and skin from the laser beam. Always wear special laser safety glasses. The machine should have safety covers or enclosures to keep the laser from escaping. Make sure the area is free of flammable materials, as the laser can start fires.

Here are some key safety tips:

- Get proper training before using a laser cleaning machine.

- Keep the workspace clean and clear of clutter.

- Remove anything that could catch fire.

- Use emergency stop buttons if something goes wrong.

Note: Laser cleaning machines can be very safe if you follow the rules. Always use the right protective gear and never look directly at the laser beam.

Laser cleaning gives you a fast, non-contact way to clean surfaces. You get a clean result without using chemicals or making a mess, but you must always think about safety first.

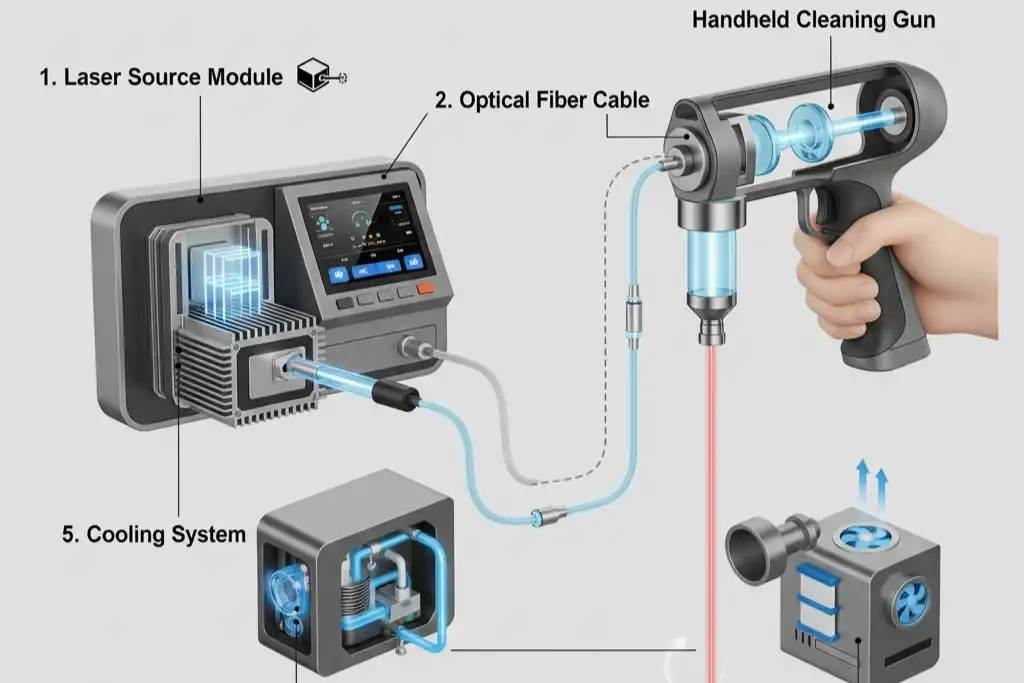

Main Laser Cleaning Machine Components

Knowing the main laser cleaning machine components helps you use your equipment well. Each part has a special job to make the laser cleaning system safe and efficient. Let’s see what parts are in a typical laser cleaning machine and how each one helps with cleaning.

Laser Source

The laser source is the most important part of a laser cleaning machine. It makes the strong beam that takes off dirt, rust, or paint. You should learn about the different laser sources and how they change cleaning.

Types of Laser Sources

Most laser cleaning machines have two main types of laser sources: pulsed lasers and continuous wave (CW) lasers.

| Laser Type | Advantages |

|---|---|

| Pulse Laser | Gives strong bursts for careful cleaning without too much heat. Good for delicate surfaces and controlled jobs. Costs more because it is precise. |

| Continuous Wave (CW) | Sends out a steady beam, good for fast, big-area cleaning. Works well for rust and thick coatings. Usually costs less but can make more heat. |

Pulse lasers are best when you need gentle, careful cleaning. Continuous wave lasers are better for big jobs where you want to clean fast.

Impact on Performance

The laser source you pick changes how well your laser cleaning system works. Here is a comparison:

| Feature | Continuous Laser Cleaning | Pulse Laser Cleaning |

|---|---|---|

| Power Delivery | Sends out steady laser energy | Gives short, controlled bursts |

| Heat Generation | Makes more heat | Makes less heat |

| Cleaning Speed | Cleans faster | Cleans slower |

| Surface Impact | Harsher on surfaces | Softer on surfaces |

| Best For | Tough cleaning jobs | Careful cleaning jobs |

If you want to clean tough things fast, you might choose a continuous wave laser. For gentle cleaning, a pulsed laser gives you more control and less chance of damage.

Optical System

The optical system is another important part of laser cleaning machines. It guides and shapes the laser beam so you can clean well.

Beam Delivery

Beam delivery is how the laser beam gets from the source to the surface. You might use mirrors, lenses, or fiber optics to move the beam. Some machines use a scanner to move the beam quickly and accurately. This helps you reach every spot and makes cleaning flexible.

Focusing Optics

Focusing optics make sure the laser beam hits the right place with the right power. These lenses or mirrors focus the energy at or just under the layer you want to remove. Good focusing helps you clean better and keeps the material safe. The angle and distance between the optics and the surface also matter. If you keep the right distance, you get even cleaning and better results.

| Aspect | Contribution to Laser Cleaning Effectiveness |

|---|---|

| Energy Delivery | How you send the laser beam changes how flexible and strong the cleaning is. |

| Focus Accuracy | Focusing right at or under the dirt makes cleaning stronger and better. |

| Angle of Incidence | A straight beam gives the most energy, but angled beams help on bumpy surfaces. |

| Standoff Distance | Keeping the right distance helps you focus and clean evenly. |

| Optical Design | The way the optics are made changes how the energy is used, which affects cleaning. |

| Motion Control Strategy | Moving the beam evenly helps you get good cleaning on all surfaces. |

Control System

The control system is like the “brain” of your laser cleaning machine. It lets you set and change how the machine works.

User Interface

The user interface is where you control the machine. You might use a touchscreen, buttons, or a computer panel. This part lets you pick settings like laser power, pulse time, and cleaning speed. A simple interface helps you work safely and get the results you want.

Automation Features

Many new laser cleaning machines have automation features. These can move the laser beam by themselves or change settings for different jobs. Automation helps you clean faster and more evenly. It also lowers mistakes and keeps cleaning safe.

Tip: A control system with good automation can help you work faster and makes your laser cleaning machine easier to use.

When you know the main laser cleaning machine components, you can pick the right machine and use it well. Each part—from the laser source to the control system—works together to give you safe, strong, and reliable cleaning.

Cooling System

The cooling system keeps the laser cleaning machine from getting too hot. Lasers make a lot of heat when they work. If the heat is not controlled, the machine can stop working or clean poorly. The cooling system helps the machine last longer and keeps you safe.

Air vs. Water Cooling

You can pick air cooling or water cooling for your machine. Each one has good points. The table below shows how they are different:

| Feature | Water Cooling | Air Cooling |

|---|---|---|

| Cooling Efficiency | High | Moderate |

| Temperature Stability | Keeps temperature steady | Changes more with room temperature |

| Environmental Adaptability | Works well in hot or dusty places | Not as good in hot or dusty air |

| Maintenance | Needs water checks and care | Just needs fan cleaning |

| Cost & Size | Costs more, takes up more space | Cheaper, smaller, and lighter |

| Best Application Scenario | Good for big jobs and long use | Good for small jobs and short use |

Water cooling is best for hard jobs and long cleaning times. Air cooling is better for small machines and quick jobs. Choose the one that fits your work.

Maintenance Needs

You need to take care of the cooling system to keep the machine working well. Here are some reasons why this is important:

- The cooling system stops the machine from getting too hot.

- Good cooling keeps cleaning results the same every time.

- A steady cooling system keeps the laser safe from heat changes.

- Checking the system often helps stop breakdowns and saves money.

Tip: Clean the fans and check the water often. This helps your machine work well and last longer.

Fume Extraction System

The fume extraction system takes away bad fumes and dust during cleaning. This keeps the air clean and helps protect your health.

Contaminant Capture

When you use the laser, it turns dirt and paint into vapor and dust. The fume extraction system catches these before they get into the air. This keeps your work area safe and helps the machine last longer.

- Clean air is better for your health and safety.

- The system keeps laser parts safe from dust.

- You follow safety rules and keep the air clean.

- The system helps stop problems and means fewer filter changes.

Filtration Methods

The fume extraction system uses filters to catch dust and fumes. You might see HEPA filters, carbon filters, or more than one filter in your machine. These filters trap tiny dust and remove bad smells. You should check and change filters often to keep the system working well.

Note: A good fume extraction system helps you stay safe and keeps your machine working right.

Safety Features

Laser cleaning machines have safety features to keep you and others safe. It is important to know what these are and how they help.

Enclosures and Shields

Enclosures and shields stop the laser beam from getting out. These barriers keep you safe from the laser. You might see metal covers, glass shields, or special curtains around the machine. These features let you work without worrying about the laser.

Emergency Stops

Emergency stops let you turn off the machine fast if there is a problem. You can press a button or use an automatic shut-off. This helps stop accidents and keeps everyone safe.

The table below shows common safety features in laser cleaning machines:

| Safety Measure | Description | Examples/Equipment |

|---|---|---|

| Operator Training | Teaches you how to use the machine safely | Training classes, manuals |

| Laser Safety Glasses | Protects your eyes from laser light | Glasses for each laser type |

| Safe Work Area | Keeps the area safe | Barriers, warning signs, light curtains |

| Ventilation and Exhaust | Removes bad fumes and dust | Exhaust fans, air filters |

| Emergency Stop Mechanism | Lets you stop the machine quickly | Emergency stop button, auto shut-off |

Always wear safety gear and follow the rules. This keeps you and your machine safe while cleaning.

Functions of Laser Cleaning Machine Components

Role in Cleaning Process

Every part in a laser cleaning machine has its own job. The laser source gives the power to take off dirt, rust, or paint. The optical system moves and points the laser beam to the right place. The control system lets you pick how strong and fast the cleaning will be. The cooling system stops the machine from getting too hot. The fume extraction system takes away dust and fumes, so the air stays clean. Safety features like shields and emergency stops keep you safe from harm.

When you use a laser cleaning machine, all these parts work together. The laser beam only hits the layer you want to remove. The main material under the dirt stays safe. This makes cleaning more gentle and exact than old ways.

Component Interactions

The parts of a laser cleaning machine must work together as a team. The laser source sends energy to the optical system. The optics point and focus the beam where you need to clean. The control system sets when and how strong the laser works. The cooling system takes away heat from the laser and optics. The fume extraction system pulls out vapor and dust made during cleaning.

Here is how the main parts work together:

- The control system tells the laser source when to start.

- The optical system points and shapes the beam.

- The cooling system keeps the laser and optics cool.

- The fume extraction system turns on when cleaning starts.

- Safety features always protect you in the background.

If one part stops working, the whole cleaning process can slow down or stop.

Troubleshooting Basics

You might have some problems with your laser cleaning machine. Knowing what to check helps you fix things fast.

- Always look at the protection window for damage before and after use.

- Clean the window after each use to stop dirt from building up.

- Change the window if you see any cracks.

- Make sure mirrors are lined up to guide the laser beam.

- Clean lenses often to keep the laser working well.

- Check the optical system for any signs of damage.

Here are some problems you might see and what causes them:

| Issue | Cause | Solution |

|---|---|---|

| Belt Tension | Belt is too loose or tight | Adjust the belt to the right tension |

| Rail Alignment | Rails are not lined up | Line up the rails for smooth movement |

| Bearing Failures | Bearings wear out over time | Check and change bearings if needed |

You should also check for errors in the software and control system. Make sure all drivers are up to date. Check that the machine connects to your computer to stop errors.

Tip: Clean and check the optic window and lenses often. This helps stop overheating and keeps your machine working well.

If you know what each part does and how to spot problems, you can keep your laser cleaning machine working for every job.

Types of Laser Cleaning Machines

Handheld vs. Automated

There are two main types of laser cleaning machines. One type is handheld. The other type is automated. Handheld machines are small and easy to carry. You can move them to different places. They work well for many cleaning jobs. You can use them in tight spaces. Automated machines are bigger and stay in one spot. They are used in factories or big workshops. These machines clean things the same way every time. This saves time and gives even results. Automated machines are good for cleaning many parts fast.

Here is a table that shows how they are different:

| Feature | Handheld Laser Cleaning Machines | Automated Laser Cleaning Machines |

|---|---|---|

| Design | Compact and portable, suitable for various applications | Integrated into industrial workflows, often larger |

| Operation | Flexible operation, ideal for diverse cleaning tasks | Optimized for repetitive tasks, enhancing throughput |

| Efficiency | Environmentally friendly and efficient for small jobs | High consistency and speed for large-scale operations |

Tip: Use handheld machines for small or tricky jobs. Use automated machines for big jobs that repeat.

Pulsed vs. Continuous Wave

Laser cleaning machines can also be pulsed or continuous wave. Pulsed lasers send out quick bursts of energy. They are good for gentle cleaning. You can use them on electronics or old items. These lasers help protect fragile surfaces. Continuous wave lasers give a steady beam. They clean fast and cover big areas. You see them in shipyards or car factories. They remove thick dirt or rust quickly.

- Continuous lasers work fast for tough cleaning jobs but may not be safe for heat-sensitive things.

- Pulsed lasers are safer for delicate parts and work best on fragile things, but they are slower on big jobs.

- Continuous wave lasers are great for factories that need fast and strong cleaning.

- Pulsed lasers give you more control and do not harm delicate items like electronics or old artifacts.

Note: Pulsed lasers keep delicate things safe. Continuous wave lasers finish big jobs fast.

Portable vs. Stationary

You can pick between portable and stationary laser cleaning machines. Portable machines are light and easy to move. You can use them in many places for different jobs. They cost less and do not need much space. Stationary machines stay in one place. They are strong and clean big or tough things. You see them in factories cleaning the same items again and again. These machines need more room and cost more to buy and keep working.

Here is a table to compare them:

| Feature | Portable Laser Cleaning Machines | Stationary Laser Cleaning Machines |

|---|---|---|

| Versatility | High; customizable settings for various tasks | Limited; designed for specific heavy-duty applications |

| Cost | Lower initial investment and operational costs | Higher initial investment and maintenance costs |

| Power Output | Lower; suitable for lighter tasks | Higher; ideal for heavy-duty and large-scale applications |

| Cooling System | Less advanced; may overheat during prolonged use | Advanced; designed for continuous operation |

| Space Requirement | Compact; can be used in various locations | Requires dedicated space for installation |

| Integration with Automation | Limited; not typically integrated into production lines | High; can be integrated into manufacturing processes |

If you need to move your machine a lot, choose a portable one. For big, nonstop cleaning, pick a stationary machine.

Laser cleaning machines come in many types. You can find one that fits your job. Some are flexible, some are fast, and some are very strong.

Component Variations

Laser cleaning machines have many different parts. These parts can change from one machine to another. The differences help you pick the best machine for your job. Some machines use special lasers. Others have different ways to cool down or send the laser beam.

The thing you want to clean is important. Metals, plastics, and ceramics act differently with laser energy. If you clean metal, you need more power and the right wavelength. Plastics need gentle settings so they do not melt. Ceramics need careful control to stop cracks.

The type of dirt matters, too. Thick rust or paint needs a strong laser and longer pulses. Thin layers or soft coatings need short pulses and less power. You can change the machine settings for each job. But you must know what each part does.

What you want the surface to look like also matters. If you want it smooth, pick a machine with fine control. Some jobs need rough surfaces for glue or paint. You set the laser to get the finish you want.

Laser power and wavelength are very important. High power cleans hard jobs fast. Low power is better for gentle cleaning. Wavelength changes how the laser works with each material. Some wavelengths are better for metals. Others work better for plastics or ceramics.

Pulse duration is how long the laser hits the surface. Short pulses clean soft things. Long pulses take off thick dirt. Some machines let you change the pulse for more choices.

Beam delivery systems are different, too. Handheld systems are good for small or tricky spots. Automated systems clean big areas fast and even. Pick the one that fits your space and job.

Cooling keeps your machine safe. Water cooling is best for hard jobs and long work. Air cooling is good for small machines and short jobs. Good cooling helps your machine last and keeps cleaning even.

Mobility and portability are important for your work. Portable machines are easy to move. Stationary machines stay in one place and do big jobs. Pick what fits how often you move the machine.

Here is a table that shows how these things change your choice:

| Factor | Description |

|---|---|

| Material Type | Metals, plastics, ceramics respond differently to laser energy. |

| Contaminant Type | Nature and thickness of contaminants change machine specifications. |

| Surface Requirements | Desired finish influences laser settings and cleaning style. |

| Laser Power | Power levels affect cleaning speed and effectiveness. |

| Wavelength | Different wavelengths suit different materials. |

| Pulse Duration | Short pulses for delicate cleaning, long pulses for thick contaminants. |

| Beam Delivery Systems | Handheld for control, automated for efficiency. |

| Cooling Methods | Water for heavy use, air for light tasks. |

| Mobility and Portability | Portable for flexible jobs, stationary for large-scale cleaning. |

Tip: Always look at the different parts before you pick a laser cleaning machine. This helps you get the best results for your job.

Each part helps the machine work better. If you know about these differences, you can choose the best machine for your cleaning needs.

Operation and Maintenance

Daily Operation Tips

You want your laser cleaning machines to work well every day. Good habits help you avoid trouble and keep your equipment safe. Here are some tips for daily use:

- Look at mirrors, lenses, and windows for dirt or dust. Clean them if you see anything dirty.

- Make sure the optical path is lined up right. If mirrors are not lined up, cleaning will not work as well.

- Check the cooling system. Look at coolant levels and watch for alarms or odd numbers.

- Check airflow and filters. If filters are blocked, cooling will not work.

- Tighten mounts and hardware. Loose parts can mess up the optics.

- Try a small test on a sample piece. See if the cleaning looks normal.

Tip: Checking your machine before you start can stop big problems later.

Maintenance for Each Component

Laser cleaning machines have many important parts. Each part needs its own care. The table below shows what to do for each part:

| Component | Maintenance Tasks |

|---|---|

| Cooling System | Check coolant and refill if needed. Clean or change air filters. Look at hoses for leaks or blocks. |

| Electrical System | Look at power cables and plugs for damage. Change bad fuses or circuit breakers. Make sure all connections are tight. |

| Additional Accessories | Clean nozzles often. Check shields for cracks or damage. Look at mounts and fasteners for problems. |

You should follow a schedule for these jobs. Regular care helps your laser cleaning machines last longer and work better.

Signs of Wear

Knowing what to look for helps you find problems early. Laser cleaning machines show wear in different ways. The table below lists common signs and what you should do:

| Sign of Wear | Description | Maintenance Practice |

|---|---|---|

| Optics Contamination | Lenses, mirrors, or windows get dirty and do not work well | Check and clean optical parts often. Use filters or air systems to keep them clean. |

| Wear and Tear of Moving Parts | Moving parts lose accuracy and cleaning gets worse | Check and oil moving parts. Change old parts before they break. |

Note: If you see any of these signs, fix them right away. Quick fixes can stop bigger problems.

Taking care of your laser cleaning machines means checking them every day, doing regular care, and watching for signs of wear. These steps help you get good results and keep your equipment working well.

Maximizing Lifespan

You want your laser cleaning machine to last a long time. Many things can change how long your equipment works well. There are some ways to help your machine stay in good shape for years.

Here are some important things you can do to make your laser cleaning machine last longer:

- Preventive Maintenance

Clean your machine often. Check all the systems regularly. Change parts that wear out before they break. Update the software when there is a new version. These steps help stop problems and keep your machine working well. - Proper Usage Guidelines

Always follow the instructions from the company that made the machine. Do not use the machine for jobs it cannot do. Watch how the machine works each time you use it. If you see something strange, stop and look for problems. Using the machine the right way stops damage and early wear. - Environmental Optimization

Keep your work area clean and free of dust. Make sure the temperature and humidity do not change too much. Protect your machine from shaking or sudden moves. A steady place helps your machine work better and last longer. - Training and Certification for Operators

Make sure everyone who uses the machine has good training. Certified users know how to use the machine safely. They can find problems early and stop mistakes that could hurt the machine. - Manufacturer Support and Warranty Services

Use the warranty and support from the company that made your machine. Maintenance plans and technical help fix problems fast. These services also give you advice and new parts when you need them.

Tip: Keeping your workspace clean and checking your machine often helps you find problems before they get worse.

Here is a table that shows how each way helps your machine last:

| Strategy | What It Does for Lifespan |

|---|---|

| Preventive Maintenance | Stops small problems from becoming big failures |

| Proper Usage Guidelines | Reduces risk of damage and early wear |

| Environmental Optimization | Keeps machine stable and safe |

| Training and Certification | Lowers chance of user errors |

| Manufacturer Support and Warranty | Provides expert help and fast repairs |

You can use all these ways together for the best results. Taking care of your laser cleaning machine saves money and stops long breaks. Your equipment will work better and last longer.

Note: You do not need special skills to keep your machine healthy. Simple habits and regular care help a lot.

If you want your laser cleaning machine to last, focus on keeping it safe and clean. Good habits and smart choices help you get the most from your machine.

Choosing the Right Laser Cleaning Machine

Application Needs

When you choose a laser cleaning machine, you need to think about what you want to clean. Each job has different needs. Some surfaces need gentle cleaning, while others need strong power. You should look at the type of material, the thickness of the dirt, and how big the area is. If you work in a factory, you may need a machine that can clean fast and handle many parts. If you work on small or delicate items, you may need a machine with more control.

Here is a table that shows what factors matter for different applications:

| Factor | Description |

|---|---|

| Cleaning Speed | How fast the machine can clean surfaces. |

| Fume Extraction | Removes dust and fumes for a safe workspace. |

| Overlap Rate | Affects how smooth and clean the surface will be. |

| Energy Density | Changes how well the machine removes dirt or rust. |

| Mobility Functions | Handheld, stationary, or cabinet types for different jobs. |

| Additional Features | Maintenance tools, cooling systems, and safety parts. |

| After-sales Service | Help from the maker after you buy the machine. |

| Budget | The price based on size, power, and technology. |

You can use this table to match your needs with the right machine.

Power and Performance

Power and performance are important when you pick a laser cleaning machine. The power level tells you how strong the laser is. High power works well for thick rust or paint. Low power is better for gentle cleaning. You should also look at cleaning speed. Fast machines save time on big jobs. Energy density is another key part. It shows how much energy hits the surface. More energy means better cleaning, but it can also change the surface.

Performance also depends on overlap rate. This is how much the laser covers each spot. A good overlap gives you a smooth finish. If you need to move the machine, look for one with good mobility. Some machines are easy to carry. Others stay in one place for heavy work.

Tip: Always check the power and speed before you buy a laser cleaning machine. This helps you get the best results for your job.

Safety and Compliance

Safety is very important when you use a laser cleaning machine. You need to make sure the machine has good safety features. Look for shields, covers, and emergency stop buttons. Fume extraction keeps the air clean and safe. Some machines have extra safety parts, like warning lights or locked doors.

You should also check if the machine meets safety rules in your area. Some places have laws about lasers and air quality. A good machine will follow these rules. This keeps you and your team safe at work.

Note: Always use the safety gear that comes with your machine. This protects your eyes and skin from the laser.

Cost Considerations

When you check out laser cleaning machines, you will notice many prices. The price depends on what the machine does and how it is made. You should know what changes the price before you buy one.

There are a few main things that change the cost of a laser cleaning machine:

- Laser power output: Machines with more power clean faster and do harder jobs. These machines usually cost more money.

- Type of laser source: Pulsed lasers use special technology for gentle cleaning. They cost more than continuous wave lasers, which are good for big areas.

- Level of automation: Machines with automatic controls or robot arms cost more than simple, hand-controlled ones.

- Cooling system efficiency: Better cooling systems help the machine work longer and safer. These systems make the price go up.

- Brand reputation: Famous brands often charge more because they give better help and have good quality.

You will also see prices change if the machine has special features, new technology, or a well-known brand name. Some machines have extra safety parts or smart controls. These things can make the price higher.

Here is a table that shows the usual prices for different kinds of laser cleaning machines:

| Category | Price Range |

|---|---|

| Entry-Level Systems (100W) | $5,000 – $7,000 |

| Mid-Range Systems (300W-500W) | $8,000 – $15,000 |

| High-Power Industrial Systems (1000W+) | $20,000 – $25,000+ |

Entry-level systems are the cheapest. They are good for small jobs or little shops. Mid-range systems have more power and features. They are good for most medium businesses. High-power industrial systems cost the most. These machines clean big areas and work for a long time in factories.

The kind of technology in each machine also changes the price. Continuous wave lasers are usually cheaper. They are good for fast cleaning on big jobs. Pulsed lasers cost more because they use special technology. You need these for careful cleaning, like on electronics or art.

Tip: Think about what you want to clean and how often you will use the machine. A higher price can mean better work and longer life, but do not pay for things you do not need.

When you look at machines, think about the total value. Look at the power, features, and help you get for the price. This helps you pick a machine that fits your needs and your budget.

You have learned about the main parts of a laser cleaning machine and what each one does. Knowing this helps you pick the best machine, use it safely, and keep it in good shape. When choosing a machine, look for safety and environmental features. If you need to clean something special, ask an expert or read more about laser cleaning machines.

Remember: Knowing what each part does helps you work safely and makes your job easier.

FAQ

What is the main purpose of a laser cleaning machine?

A laser cleaning machine takes off rust, paint, or dirt. The laser does not touch the item. This keeps fragile things safe.

What types of materials can you clean with a laser cleaning machine?

You can clean metal, plastic, ceramic, and glass. The machine works best on things that soak up laser energy.

What safety gear do you need when using a laser cleaning machine?

You must wear laser safety glasses and special clothes. Shields and covers help keep you safe from the laser.

What maintenance tasks should you do regularly?

You need to clean the lenses and check the cooling system. Change filters often. Doing these things helps your machine last longer.

What makes laser cleaning better for the environment?

Laser cleaning does not use water or chemicals. You do not make toxic waste or cause pollution. The dirt turns into vapor.

What problems can happen if you skip maintenance?

If you skip care, cleaning will not work well. The machine can get too hot or break. Not doing maintenance makes the machine wear out faster.

What features should you look for when choosing a laser cleaning machine?

Look for machines with power you can change. Good cooling and strong safety are important. Easy controls help you use the machine. Pick one that fits your cleaning jobs.

See also

The Working Principle of Laser Cleaning for Beginners

Common problems and solutions in the use of laser cleaning machines

How to Use a Customized Laser Cleaning Solution for Better Results

How to combine laser cleaning machine with industrial robots