You will see that laser cleaning is much faster than manual polishing. Laser cleaning is quicker and makes less noise. It gives a cleaner surface with less waste and better sticking. Manual polishing takes more time and makes more trash. It also costs more money over time. Laser cleaning is also better for the environment.

| Metric | Laser Cleaning | Manual Polishing |

|---|---|---|

| Cleaning time / gear | 14 s | 48 s |

| Typical scrap rate | <0.5% | 4% |

| Noise level (dB) | 70 | 95 |

| Cost (initial investment) | $22,000 | $14,000 + $9,000 yearly grit |

| Environmental impact | Low | High |

| Adhesion improvement | 20-35% | N/A |

Laser cleaning uses a laser beam to take off dirt or coatings. Manual polishing uses tools and grit to clean surfaces. You will see a simple and clear comparison in the next parts.

Key Takeaways

- Laser cleaning works faster than manual polishing. It saves time on big jobs. Laser cleaning makes less waste. It is better for the environment. It does not use harmful chemicals. Laser cleaning gives a smoother surface finish. It is very precise and lowers the chance of scratches. Laser cleaning costs more at first. But it saves money later by needing fewer supplies and less work. Manual polishing is good for small and detailed jobs. But it takes more time and uses more materials.

Efficiency Overview

Main Findings

Laser cleaning works better than manual polishing. It cleans faster and makes less noise. It also makes less waste and does not use toxic chemicals. Laser cleaning uses less energy and gives a smoother surface. You can control the process more, so you get the same results each time.

Here is a table that shows how the two methods are different:

| Aspect | Laser Cleaning | Manual Polishing |

|---|---|---|

| Energy Application | Substantial reduction in applied energy | Higher energy consumption |

| Surface Treatment | Effective removal of contaminants | Less effective in removing certain contaminants |

| Toxicity | No toxic liquids required | Potential use of harmful chemicals |

| Efficiency | Tailored treatment possible | Less control over treatment parameters |

You can check how well each method works by looking at some numbers. These include roughness average (Ra), root mean square roughness (RMS), chromium-to-iron ratio, surface reflectivity, and performance tests. Lower Ra and RMS mean the surface is smoother. A higher chromium-to-iron ratio means better protection from rust. Gloss meters help you see how shiny the surface is. Tests like salt spray and copper sulfate show how well the surface fights rust.

Direct Comparison

If you look at both methods side by side, you see big differences. Laser cleaning is much faster at removing material. It can remove up to (21 ± 2) mm³/min. Manual polishing is slower and cannot keep up. Laser cleaning also makes the surface much smoother. The roughness goes from Ra = (24 ± 4) µm to Ra = (0.32 ± 0.04) µm. Manual polishing leaves the surface rougher and less shiny.

Laser cleaning saves more time, especially for bigger parts. The bigger the part, the more time you save. Manual polishing takes longer and does not work as well for large jobs. Laser cleaning also makes less waste and has lower scrap rates. It does not use harmful chemicals and is quieter, so your workspace is safer and cleaner.

Tip: If you want the fastest and cleanest results, pick laser cleaning. You will save time and energy and get a better finish.

Laser Cleaning Overview

How Laser Cleaning Works

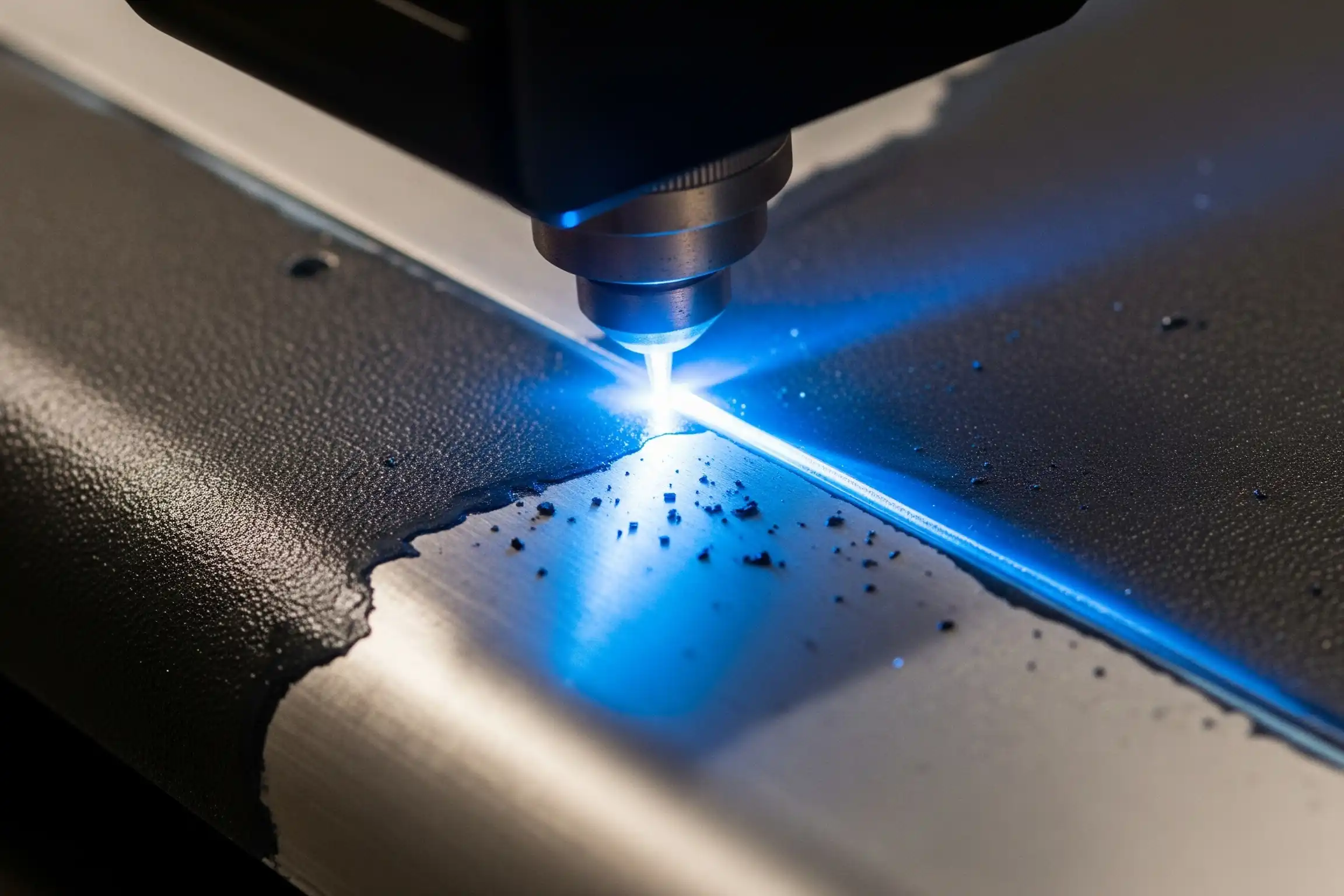

Laser cleaning takes away things you do not want on surfaces. It uses a laser beam to hit dirt, rust, paint, or coatings. The laser beam goes after the dirty parts, not the clean ones. Dirty spots soak up the laser energy more than clean spots. When the laser touches the dirt, it gets hot very fast. The dirt then breaks apart or disappears. The clean surface does not get as hot, so it stays safe.

Laser cleaning uses something called selective absorption. The laser only heats up the places you want to clean. This makes the unwanted stuff heat up and come off. You do not need to use chemicals or rough tools. The process is called laser ablation. The laser meets the surface, and its energy turns into heat. This heat gets rid of the dirt or lifts it away.

New technology makes laser cleaning work even better. Circular scanning helps stop hot spots and keeps things safe. Modern machines let you change settings like power and speed. You can pick the best settings for each job.

Tip: Hybrid laser cleaning systems use both continuous and pulsed lasers. These systems clean faster and give better results, especially for paint removal.

Typical Uses

Laser cleaning is used in many places. Here are some examples:

- Automotive: Clean car parts, take off rust, and get ready for painting.

- Aerospace: Clean airplane parts and remove oxides.

- General industrial applications: Clean molds, tools, and machines.

- Weld cleaning: Take away leftover stuff after welding.

- Mold cleaning: Keep molds clean and free from buildup.

- Surface preparation: Get surfaces ready for glue or bonding.

Laser cleaning works on rust, oxides, paints, coats, and electrolytes. You can use it on metals, plastics, and other surfaces. This process helps you save time and make less trash at work.

Manual Polishing Overview

How Manual Polishing Works

Manual polishing means you use your hands and simple tools. You do this to make surfaces look and feel better. First, you gather your supplies. You need things like car shampoo, buckets, and grit guards. You also need wet sanding discs and microfiber sponges. Gentle brushes and drying cloths help too. Clay bars and quick detailers are used for cleaning. Paint correction products fix scratches. You use applicator pads and polishing cloths. Sometimes you use wax or sealant. If you want, you can use a dual-action polisher.

Here is a list of common tools and supplies you use for manual polishing:

- Car shampoo or wash solution

- Two buckets

- Grit guard

- Wet sanding discs

- Microfiber sponges or mittens

- Gentle bristle brushes

- Drying cloths (microfiber)

- Clay bar or clay for detailing

- Quick detailer or clay lubricant

- Paint correction products (scratch remover, compound, polish)

- Dual-action polisher (optional)

- Applicator pads or polishing pads

- Polishing cloths or microfiber towels

- Wax or paint sealant (optional)

You follow steps to get the best results. First, you use heavy compounding to fix deep scratches. Then, you use a lighter polish to smooth and shine the surface.

Tip: Always use clean tools and new products. This stops scratches and keeps your finish looking nice.

Typical Uses

Manual polishing is good for many jobs. People use it in jewelry making and car work. It is also used for electronics and in factories. Construction workers use it too. You pick manual polishing for small or detailed parts. It helps you reach tight spots and delicate areas.

- Jewelry making

- Automotive detailing

- Electronics finishing

- Manufacturing

- Construction

Manual polishing lets you control how you work. You can change pressure and technique for each surface. You use it for a high-quality finish and for tricky shapes. Manual polishing is important in jobs where looks and surface quality matter.

Speed Comparison

Laser Cleaning Speed

Laser cleaning works much faster than manual polishing. Many industries use laser cleaning to save time. It can clean up to 20 square meters per hour for light rust. If the rust is heavy, it cleans 5 to 10 square meters per hour. Removing one layer of paint takes 10 to 15 square meters per hour. If there are many layers, it cleans 3 to 7 square meters per hour. When you get surfaces ready for welding, it cleans about 10 to 12 square meters per hour. For adhesion improvement, it can clean up to 25 square meters per hour.

| Application | Cleaning Speed (square meters per hour) |

|---|---|

| Light Rust | Up to 20 |

| Heavy Rust | 5-10 |

| Single Layer Paint | 10-15 |

| Multi-Layer Coatings | 3-7 |

| Welding Preparation | 10-12 |

| Adhesion Improvement | 15-25 |

Some things change how fast laser cleaning works. You can change scanning speed and focal length. Fast scanning covers more space but may miss some dirt. Slow scanning helps clean tough spots better. Short focal length works well for thin layers. Long focal length is good for big areas but uses less energy.

- Fast scanning can miss some dirt.

- Slow scanning helps clean hard spots.

- Short focal length is best for thin layers.

- Long focal length works for large areas.

Tip: Change laser settings for each job to get the best results.

Manual Polishing Speed

Manual polishing takes more time and hard work. You use tools and abrasives by hand or with machines. The speed depends on the material and your skill. You should test different speeds on sample pieces. Write down what works best for next time.

Here are some things that change how fast you polish:

- Change speed for each material.

- Try different speeds on samples.

- Keep notes of what works well.

Polishing glass needs fine abrasives so you do not scratch it. Wood can get ruined if you sand too much. Stone needs special ways because it is very hard. The kind of material, the quality of abrasives, and your skill all matter. Temperature and humidity also change how fast you polish. Machines that are clean and working help you finish faster.

| Factor | Description |

|---|---|

| Type of Material | Each material needs a different way and speed. |

| Quality of Abrasives | Good abrasives help you polish faster and smoother. |

| Operator Skill | Skilled workers finish jobs quicker and better. |

| Environmental Conditions | Temperature and humidity change how fast you polish. |

| Machine Maintenance | Clean machines help you keep a steady pace. |

Manual polishing usually takes much longer than laser cleaning. You spend more time on each part, especially if you want a smooth finish.

Quality & Precision

Surface Finish

You want a surface that looks smooth and feels clean. Laser cleaning gives you a finish that is even and bright. The laser removes dirt, rust, and paint without scratching the surface. You see fewer marks and less roughness. The process leaves the metal or material shiny and ready for the next step. You do not need to worry about leftover grit or streaks.

Manual polishing can make surfaces look good, but you must work carefully. If you press too hard or use the wrong tool, you may scratch or damage the surface. You often see swirl marks or uneven spots. The finish depends on your skill and the quality of your tools. You may need to polish the same area many times to get a smooth look.

| Method | Surface Finish Quality | Risk of Scratches | Consistency |

|---|---|---|---|

| Laser Cleaning | Very smooth, shiny | Low | High |

| Manual Polishing | Can be smooth | Medium to High | Low |

Tip: If you want a surface that looks perfect every time, laser cleaning helps you reach that goal.

Precision Control

Laser cleaning gives you strong control over the cleaning process. You can set the power, speed, and focus of the laser. This lets you clean only the areas you want. You avoid touching or damaging the material underneath. The laser works without contact, so you do not add pressure or stress. You can remove tiny bits of dirt or paint, even at the nanometer scale. This makes laser cleaning great for delicate surfaces.

Manual polishing does not give you much control. You use your hands or simple machines. You may press too hard or miss small spots. You risk damaging the surface, especially if it is soft or thin. Manual polishing cannot match the precision of a laser. You must rely on your skill and experience.

- Laser cleaning systems let you adjust settings for high precision.

- Manual polishing can damage the substrate and lacks automation.

- Laser cleaning removes only what you want, leaving the rest untouched.

- The non-contact method keeps the surface safe and smooth.

Note: Laser cleaning helps you work with fragile or valuable items. You get a clean result without risking damage.

Cost Analysis

Initial Investment

You should think about how much money you need first. Laser cleaning equipment costs more than manual polishing tools. You pay extra for new technology and special features. Pulse laser cleaning machines cost between $6,000 and $33,000. CW laser cleaning systems cost less, from $3,000 to $7,500. Manual polishing tools are much cheaper. You only need simple hand tools and abrasives. Sometimes you buy a small machine.

| Equipment Type | Cost Range |

|---|---|

| Pulse Laser Cleaning | $6,000 – $33,000 |

| CW Laser Cleaning | $3,000 – $7,500 |

| Manual Polishing Tools | Generally lower |

Laser cleaning costs more at first, but it works faster. You also get better results. Manual polishing costs less, but you spend more time. If you have big jobs or need high precision, laser cleaning can save money later.

Tip: If you want to clean many surfaces or grow your business, buying laser cleaning equipment helps you work faster and do more jobs.

Operating Costs

You also need to think about costs after you buy your tools. Laser cleaning machines need regular care. You must calibrate the system to keep results steady. You clean optical parts so the laser works well. Software updates help your machine run right. You also need to lubricate moving parts to stop wear. Manual polishing tools need less care. You check for damage and keep them clean. You also lubricate moving parts, but you do not need software or calibration.

| Maintenance Task | Laser Cleaning Equipment | Manual Polishing Tools |

|---|---|---|

| Calibration | Regular calibration is essential for consistent results. | N/A |

| Deep Cleaning of Optical Components | Requires specialized cleaning to maintain performance. | N/A |

| Software Updates | Regular updates are necessary for optimal operation. | N/A |

| Mechanical Inspections | N/A | Focus on mechanical inspections. |

| Lubrication of Moving Parts | Regular lubrication is needed to prevent wear. | Lubrication is also required. |

Laser cleaning uses less grit and fewer supplies. You do not buy chemicals or replace pads often. Manual polishing needs new abrasives and cleaning products all the time. Over months or years, these costs add up. Laser cleaning saves you money on supplies and labor.

Note: You spend more on laser cleaning at first, but you save on supplies and time. Manual polishing costs less to start, but you pay more for materials and labor as you keep working.

Safety Factors

Laser Cleaning Safety

You need to be careful with laser cleaning. Lasers can hurt you if you do not follow rules. Before you start, check for dangers and write them down. Use safety glasses and put up warning signs. A Laser Safety Officer helps you follow safety rules and keeps records.

| Aspect | Description |

|---|---|

| Risk Assessment | Look for dangers and decide how risky the job is. |

| Safety Controls | Use safety gear and work safely. |

| Laser Safety Officer (LSO) | The LSO makes sure everyone follows safety rules and writes down safety steps. |

| Documentation | Write down all safety checks and controls. |

| Class 4 Laser Systems | Take extra safety steps for Class 4 lasers, which are used in laser cleaning. |

You must register Class 3b and 4 lasers. Put up clear signs so people know about the lasers. Always wear safety glasses that are certified. Follow safety steps to avoid getting hurt by lasers.

- Use laser safety enclosures and barriers.

- Work in areas made for lasers.

- Make sure barriers block the laser’s light and power.

Tip: Never look at the laser beam. Check your safety gear before you start.

Manual Polishing Safety

Manual polishing can also be dangerous. You can get hurt by flying bits, loud sounds, or dust. Use guards on machines and wear eye protection. Do not wear loose clothes or jewelry. They can get caught in moving parts. Hot surfaces and sparks can burn you, so be careful. Dust from polishing can hurt your lungs, so wear a mask and use dust control tools. Loud noise can hurt your ears, so wear ear protection.

| Safety Risk | Mitigation Strategy |

|---|---|

| Flying Debris | Use guards and wear eye protection. |

| Entanglement | Do not wear loose clothes or jewelry. |

| Burns | Watch out for hot surfaces and sparks. |

| Dust Inhalation | Use dust control and wear a mask. |

| Noise Exposure | Wear ear protection. |

Note: Keep your workspace clean and check your tools before you start. Being safe helps you work better and stops accidents.

Environmental Impact

Energy Efficiency

It is good to pick a cleaning method that saves energy. Laser cleaning uses less energy than manual polishing. Pulse laser cleaning machines run on electricity. They do not need lots of water or extra power. Modern fiber laser systems give strong results but use less energy. You do not need to buy abrasives or chemicals. This means you use less energy and make less pollution.

Manual polishing needs more energy. You use machines, water, and many supplies. It takes more time and effort. This means you use more energy and make more waste. If you want to save money and help the earth, laser cleaning is better.

Tip: Energy-saving equipment helps you spend less and protect nature.

Chemical Use

Manual polishing uses many chemicals and abrasive particles. These chemicals can hurt the environment. You use things like hydrogen peroxide, citric acid, and corrosion inhibitors. Each chemical makes a different amount of pollution. Using more chemicals means more pollution.

| Chemical | Carbon Intensity (gCO2-eq/g) |

|---|---|

| UPW | 0.0104 |

| H2O2 | 1.0 |

| Citric Acid | 0.26 |

| BTA | 1.4 |

| Abrasive Particles | 0.26 |

You often use these chemicals in manual polishing:

- Abrasive particles: silica, alumina, magnesia, ceria, zirconia

- Oxidizers: hydrogen peroxide, copper sulfate, potassium permanganate

- Chemical agents: surfactants, buffing agents, complexing agents, corrosion inhibitors

Laser cleaning does not use chemicals or abrasives. You avoid toxic waste and help nature. If you want a safer and cleaner workspace, pick laser cleaning.

Note: Using fewer chemicals keeps air and water clean for everyone.

Applications

Best Uses for Laser Cleaning

Laser cleaning works in many places. It removes dirt, rust, and coatings fast. Factories use it to clean machines and tools. Museums use it to protect old art and statues. Hospitals use it to clean medical tools. The table below shows where laser cleaning is used most:

| Application Area | Industry Examples |

|---|---|

| Mold Cleaning | Food, Plastic, Rubber, Composite, Glass |

| Oil and Grease Removal | Various Industrial Applications |

| Surface Preparation for Adhesives | Automotive, Aerospace |

| Cultural Heritage Conservation | Museums, Historical Sites |

| Industrial Equipment Maintenance | Automotive, Aerospace |

| Medical Equipment Cleaning | Healthcare |

| Welding and Brazing Preparation | Manufacturing |

| Surface Preparation for Marking | Automotive, Aerospace, Medical Equipment |

You can clean molds and get surfaces ready for glue. Laser cleaning removes oil and grease from machines. Museums use lasers to keep old things safe. Hospitals use lasers to make tools clean and safe.

Tip: Pick laser cleaning if you want a quick, exact, and chemical-free way to clean.

Best Uses for Manual Polishing

Manual polishing is good for small and careful jobs. You use it for jewelry and gemstones. It helps fix tiny scratches and makes things smooth. Here are some ways people use manual polishing:

- Polish gold, silver, and platinum.

- Remove tiny scratches.

- Buff gemstones.

- Polish and smooth floors.

- Get surfaces ready for sealing.

- Make surfaces flat.

Manual polishing lets you control your work. You can work on small shapes and fragile things. It is great for finishing and fixing items.

Limitations

Each method has limits you should know. Laser cleaning costs more at first. You need training and must follow safety rules. Some surfaces do not work well with lasers. Manual polishing takes longer and needs more effort. If you rush, the results may not look even. Chemicals and dust can hurt your health and the earth.

Note: Choose the method that fits your job, money, and safety needs. You get better results when you pick the right way.

Laser cleaning is quicker and gives a nicer finish. It also makes your workspace safer. Manual polishing is cheaper at first. But you spend more time and use more supplies. The table below can help you decide:

| Need | Best Method |

|---|---|

| Speed | Laser Cleaning |

| Small Details | Manual Polishing |

| Safety | Laser Cleaning |

| Low Cost | Manual Polishing |

Tip: Look at how big your job is. Think about how much money you have. Make sure you stay safe when you choose a method.

FAQ

What surfaces can you clean with a laser?

You can clean metals, plastics, stone, and some painted surfaces with a laser. Always check if your material can handle laser energy. Some soft plastics or delicate finishes may not work well.

Is laser cleaning safe for beginners?

Laser cleaning is safe if you follow safety rules. You must wear protective glasses and use barriers. Read the manual before you start. Ask a trained person for help if you are new.

How often do you need to replace supplies for manual polishing?

You need to replace abrasives, pads, and chemicals often. The more you polish, the faster you use them up. Manual polishing costs more over time because you keep buying supplies.

Tip: Keep extra pads and abrasives on hand. This helps you finish jobs without delays.

Which method is better for large projects?

| Project Size | Best Method |

|---|---|

| Small | Manual Polishing |

| Large | Laser Cleaning |

You should use laser cleaning for big jobs. It works faster and saves you time. Manual polishing is better for small or detailed work.

See also

Which Cleaning Method Wins Fiber Laser or Ultrasonic

Laser cleaning vs. dry ice cleaning: which is more environmentally friendly