You should know that laser welding is a new way to join metals and plastics. It works with high precision. Manufacturers use this technology more now. Automated systems help when there are not enough workers. These systems also keep weld quality the same. Many industries use small and energy-saving machines. These include automotive, electronics, and medical devices. New changes in real-time beam control help a lot. Adaptive monitoring also makes strong welds easier to get.

Key Takeaways

- Laser welding joins metals and plastics with a strong light beam. It can make very precise welds.

- Pick the right welding type for the material thickness. Use heat conduction for thin sheets. Use keyhole welding for thick materials.

- Keep the machine clean and check it often. This helps make strong and safe welds.

- Safety is very important. Always wear safety gear. Follow safety rules to avoid accidents.

- Buying a good laser welding machine can save time. It can help you finish projects faster and do more work.

Laser Welding Basics

What Is Laser Welding

Laser welding is a modern joining method that uses a focused beam of light to connect materials. You can use it to join metals like stainless steel, carbon steel, aluminum alloys, titanium, and nickel-based superalloys. It also works with many types of thermoplastics. This process stands out because it can join thin and dissimilar metals with high accuracy. You will find laser welding in industries that need strong, clean welds and precise control.

When you weld plastics, you need to pay attention to the layers. The upper layer must let the laser pass through, while the lower layer must absorb the laser energy and turn it into heat. Both layers must touch each other closely. The materials must also match in how they melt and stick together. Clean surfaces and the right joint shape help you get the best results.

Note: Laser welding requires careful setup. You need to make sure the joint is clean and the parts fit together well. This helps you get a strong weld every time.

How Laser Welding Works

You use a high-energy laser beam to heat the materials at the joint. The laser creates a small, hot pool of melted material. This molten pool forms where the two pieces meet. As the pool cools, the materials fuse together and form a strong bond.

Here is what happens during the process:

- The laser beam focuses on the joint area.

- The intense heat melts the material at the surface.

- A molten pool forms, joining the two pieces.

- Sometimes, gas pressure helps push out extra molten material.

- The pool cools and hardens, creating a solid weld.

Laser welding lets you work quickly and with great precision. You can join different metals without making too many unwanted compounds. For example, you can weld aluminum to steel by aiming the laser just right. This method keeps the weld strong and clean.

Key Components

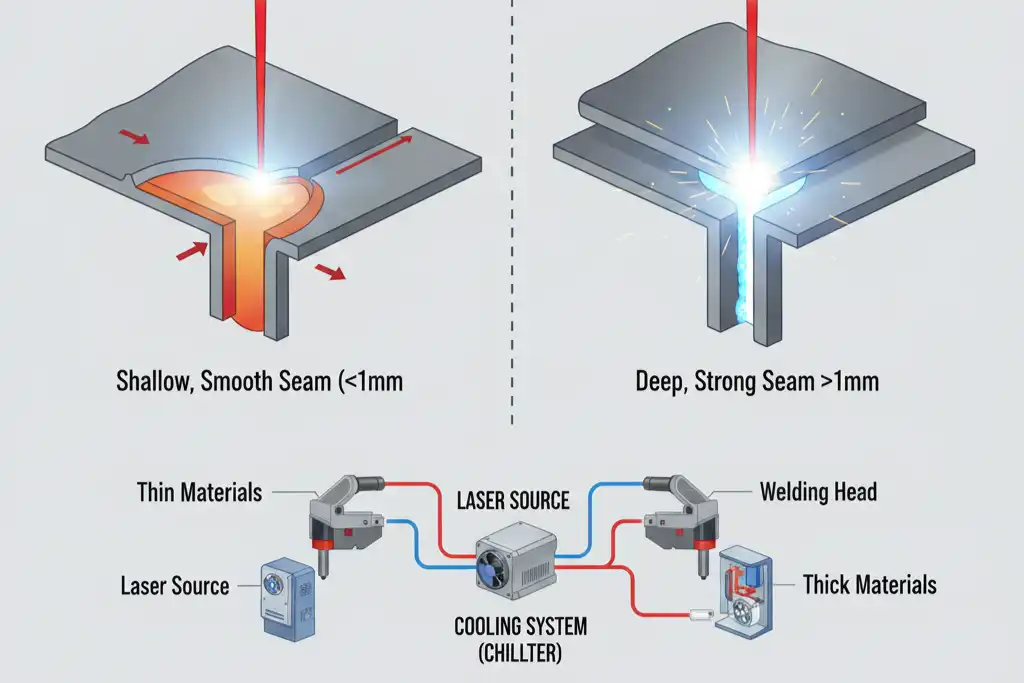

A laser welding system has several important parts. Each part plays a key role in making sure you get a good weld. Here is a table that shows the main components and what they do:

| Component | Function |

|---|---|

| Laser source | Provides the focused light beam; uses fiber lasers for long life and low energy use. |

| Chiller | Keeps the system at the right temperature; works efficiently and reliably. |

| Welding head | Directs the laser beam; has adjustable nozzles for different welding tasks. |

| Wire feeder | Feeds welding wire at a steady speed; can be adjusted for different jobs. |

Modern laser welding machines often do more than just weld. Many can also cut and clean materials. You can use one machine to join, cut, and clean parts, which saves time and boosts productivity. These machines use smart controls and special nozzles to switch between tasks easily. You get strong, precise welds and can prepare surfaces for better results.

Tip: When you choose a laser welding machine, look for one that can handle multiple tasks. This makes your work faster and more flexible.

Laser Welding Types

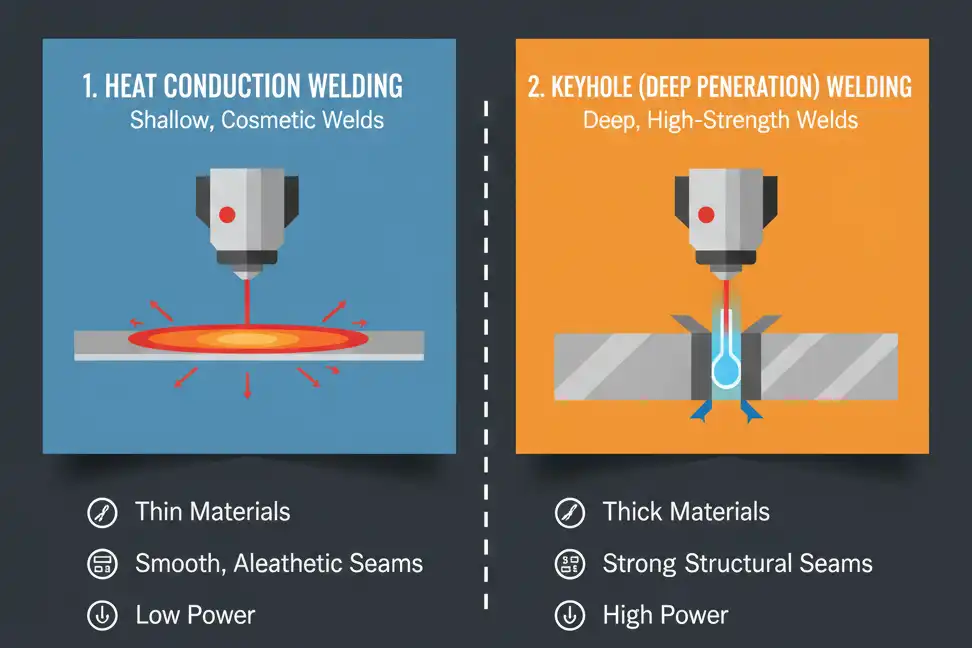

Heat Conduction Welding

Heat conduction welding is good for thin metal sheets. It makes welds that look smooth and clean. You use this method for stainless steel or aluminum foil. The laser melts just the surface of the metal. It does not make vapor or deep holes. The welds are shallow and have a nice finish. Appliance housings and medical devices use this type. You need neat and precise joints for these products.

Tip: Pick heat conduction welding for thin materials if you want them to look good.

Keyhole Welding

Keyhole welding is used for thicker materials. The laser makes a small hole called a keyhole. It melts and vaporizes the metal. This lets heat go deep into the joint. The welds are strong and go deep. Automotive and aerospace industries use keyhole welding. They need strong parts for their products. Do not use this method for thin sheets. It can hurt or damage them.

- Keyhole welding makes welds that are very strong.

- You can join thick metals like steel plates and heavy alloys.

- This process is best when you need deep and strong welds.

Main Differences

You should know how heat conduction welding and keyhole welding are different. The table below shows what makes them unique:

| Welding Type | Penetration Depth | Suitable Materials | Common Uses |

|---|---|---|---|

| Heat Conduction Welding | Shallow | Thin metals, foils | Appliance, medical housings |

| Keyhole Welding | Deep | Thick metals, alloys | Automotive, aerospace structures |

Pick the right welding type for your material thickness. Heat conduction welding is for thin sheets. Keyhole welding is for thick plates. Using the wrong type can make weak or broken welds.

Laser welding uses different laser sources for each job. The table below helps you pick the best laser for your material:

| Laser Type | Recommended For | Notes |

|---|---|---|

| Direct-diode lasers | Thin metals | Fast processing, uses less power, not good for thick metals. |

| Nd:YAG lasers | Thick materials | Precise control, deep welds, works for many alloys. |

| Fiber lasers | Both thin and thick | Works for many thicknesses, very precise. |

Note: Always match your welding type and laser source to your material thickness to get the best welds.

Laser Welding Advantages & Disadvantages

Key Benefits

Laser welding has many good points compared to older welding ways. It makes welds that are very strong and clean. You can join parts with tricky shapes or different materials. The parts you weld do not get too hot. This keeps your finished product looking nice. You do not need to do much extra work after welding.

Here is a table that shows how laser welding is different from other welding:

| Advantage | Laser Welding | Other Techniques |

|---|---|---|

| Precision | Welds as narrow as 0.1mm | Varies, generally wider |

| Speed | Up to 10 times faster | Slower than laser welding |

| Heat-Affected Zone (HAZ) | Very low | Typically larger |

| Material Versatility | Wide range including metals and plastics | Limited to specific materials |

| Post-Processing | Minimal | Often requires extensive finishing |

You can control the heat very well. The area near the weld does not get too hot. The rest of your part stays strong and keeps its shape. Laser welding uses less energy and makes less waste. This helps the environment because there are fewer bad fumes.

Tip: Laser welding can make welds as strong or stronger than the metal you start with. Some tests show the weld can be up to 300% stronger in the best cases.

Common Challenges

There are also some hard parts about laser welding. The machines cost a lot more than regular welding machines. A simple laser welding machine can cost $30,000 or even $500,000. A basic regular welding machine can cost about $2,000.

Here are some problems you might have:

| Challenge | Description |

|---|---|

| Beam Quality | Bad beam quality can make weak welds. |

| Heat Input Control | You must control heat well to stop warping or cracks. |

| Safety Issues | The laser can burn skin or hurt eyes, so you must be careful. |

| Maintenance and Calibration | You need to check and adjust the machine often to keep welds good. |

| Material Reflectivity | Shiny metals can bounce the laser, making bad welds or hurting the machine. |

| Joint Fit-Up Tolerances | Parts must fit together very closely for the weld to work well. |

| Focus Spot Size | If the laser is not focused right, the weld can be weak or too shallow. |

| High Starting Costs | The price of equipment and training can be hard for beginners or small shops. |

Laser welding needs careful setup and skilled workers. If you do not control the process, you can get bad welds or ruin your parts. You must follow safety rules because the laser is very strong.

Note: Even though the machines cost a lot at first, you might save money later. Laser welding uses less energy and does not need as much fixing.

Applications & Equipment

Common Uses

Laser welding is used in many places. It is found in big factories and sometimes at home. People use it to join metals and plastics. It is good when you need strong and neat welds. Here is a table that shows where laser welding is used:

| Industry | Applications |

|---|---|

| Automotive | Battery packs, chassis, exhaust systems, body assembly |

| Consumer Goods | Appliances, sporting goods like bicycles and golf clubs |

| Electronics | Connectors, battery terminals, pressure-sensitive seals, miniaturized components |

| Jewelry and Art | Fine jewelry, decorative pieces |

Laser welding makes strong bonds in electronics. It gives you neat joints with low resistance. This is important for small parts like connectors and battery terminals.

You can use laser welding for home projects too. It helps fix thin metals or join different materials. Some things are hard to weld with other ways, but laser welding works.

Beginner Equipment

If you want to try laser welding, start with a small machine. Handheld machines are easy to use and do not need much space. You can weld many materials, like plastics and metals. The settings can be changed for your project. The controls are simple, so you can learn fast. Many small shops and hobbyists like these machines. They are flexible and work well.

When you pick a machine, check for safety features. Make sure it works with the materials you want to weld. It should fit your workspace and your budget.

Safety Tips

Laser welding can be risky if you do not follow rules. You must wear the right gear to stay safe. Here is a table of what you need:

| Protective Equipment | Description |

|---|---|

| Safety glasses or goggles | Protect your eyes from laser light; must meet ANSI Z136.1 or EN 207 standards. |

| Protective gloves | Use flame-resistant gloves made from Kevlar or leather. |

| Anti-laser face shield | Shields your face and neck from radiation and spatter. |

| Flame-resistant clothing | Wear clothing that covers your body and meets safety standards. |

| Mask | Use a mask to avoid breathing in fine particles and gases. |

You should keep your work area clean and tidy. Make sure there is good airflow to remove fumes. Always follow safety rules like OSHA and ANSI. Training can help you learn and stay safe while working.

You should keep these important ideas in mind about laser welding:

- Use the right laser settings and clean your machine often. This helps you make strong welds.

- Laser welding is quick. It is good for small and exact jobs.

- This technology saves money later because it makes less waste.

You can find beginner lessons, online help, and forums to learn more. Laser welding is getting better with smart tools and ways to help the planet. There will be even more things you can do with it soon.

FAQ

What materials can you weld with a laser?

You can weld metals like steel, aluminum, titanium, and nickel alloys. Many thermoplastics can be joined too. Always check if your material fits the laser type and thickness.

What safety steps should you follow during laser welding?

Wear safety glasses and gloves. Put on flame-resistant clothes. Keep your workspace neat. Use shields for your face. Follow safety rules from OSHA and ANSI.

What makes laser welding different from other welding methods?

Laser welding uses a focused light beam. It gives you clean and precise welds. Less heat is used in the process. You can join thin or different materials. Laser welding is faster than most other welding ways.

What beginner equipment do you need for laser welding?

You need a handheld laser welding machine and safety gear. Make sure your workspace is clean. Pick a machine that fits your project and material. Start with easy controls so you can learn fast.

How to Remove Rust from Metal: 11 Different Methods

Step-by-Step Guide to Calculating ROI for Laser Cleaning

How to determine if a laser cleaning machine is worth buying

Comparison of efficiency between laser cleaning and manual polishing