You can use a 3000W fiber laser to cut thick materials. But each metal has a different cutting limit. For example, you can cut carbon steel up to 20mm thick. Stainless steel can be cut up to 10mm thick. Aluminum can be cut up to 8mm thick. Check the table below to compare them:

| Material | Maximum Cutting Thickness |

|---|---|

| Carbon Steel | 20mm |

| Stainless Steel | 10mm |

| Aluminum | 8mm |

How thick you can cut depends on the metal type. It also depends on machine settings and the gas you use. Knowing these limits helps you pick the right material. It also helps you plan your project safely.

Key Takeaways

- A 3000W fiber laser can cut carbon steel up to 20mm. It can cut stainless steel up to 10mm. It can cut aluminum up to 8mm. Pick the right material for your project.

- Change laser power and speed for different thicknesses. Use more power for thicker materials. Go slower for thick materials to get clean cuts.

- Pick the right assist gas. Use oxygen for carbon steel. Use nitrogen for stainless steel and aluminum. This helps make better cuts.

- Take care of your laser machine often. Clean the lenses. Check for parts that are worn out. This helps your machine cut well.

- Stay safe by wearing protective gear. Keep your workspace clean. Follow all the rules when using the machine.

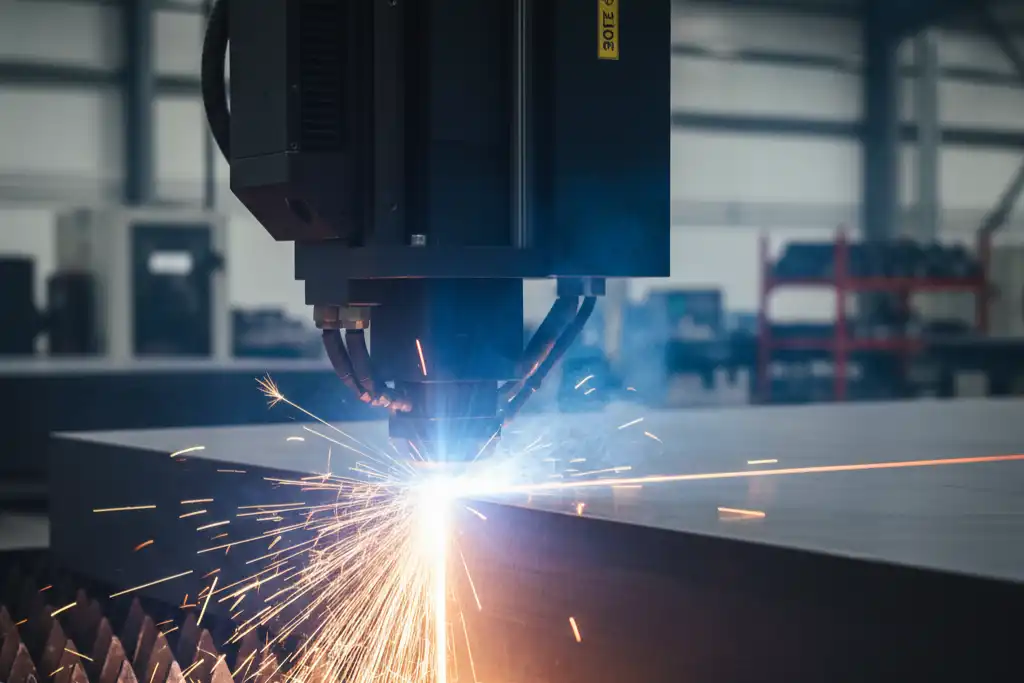

3000W Fiber Laser Cutting Limits

Carbon Steel Thickness

You can cut carbon steel up to 20mm thick with a 3000W fiber laser. This power level gives you the ability to handle most common carbon steel sheets and plates. When you cut carbon steel at this thickness, you get clean edges and a smooth finish. You can use this for making machine parts, frames, or construction pieces. If you want to cut thicker carbon steel, you need a higher power laser.

Tip: For the best results, use oxygen as the assist gas when cutting carbon steel. Oxygen helps the laser cut faster and improves the edge quality.

Stainless Steel Thickness

A 3000W fiber laser can cut stainless steel up to 10mm thick. Stainless steel is harder to cut than carbon steel because it reflects more light and has a higher melting point. You can still get precise cuts and good edge quality at this thickness. Many industries use this for kitchen equipment, medical tools, and decorative panels.

You should use nitrogen as the assist gas for stainless steel. Nitrogen keeps the cut edge bright and free from oxidation. This is important if you want a clean, shiny finish.

Aluminum Thickness

You can cut aluminum up to 8mm thick with a 3000W fiber laser. Aluminum reflects laser light more than steel, so it is harder to cut. You need to use the right settings and a clean lens for the best results. Many people use this for making signs, panels, and machine covers.

Note: Use nitrogen as the assist gas for aluminum. Nitrogen helps prevent oxidation and keeps the cut edge smooth.

Thickness Range Overview

Here is a quick summary of the maximum cutting thickness for each material with a 3000W fiber laser:

- Carbon Steel: up to 20mm

- Stainless Steel: up to 10mm

- Aluminum: up to 8mm

| Material | Maximum Thickness (mm) |

|---|---|

| Carbon Steel | 20 |

| Stainless Steel | 10 |

| Aluminum | 8 |

You can see that the 3000W fiber laser works best with carbon steel. It can also handle stainless steel and aluminum, but the maximum thickness is lower. Always check the material type before you start your project. This helps you choose the right settings and get the best results.

Factors Influencing Cutting Thickness

Material Properties

The kind of metal you want to cut is important. Some metals are easier to cut than others. Here are the main things that matter:

- Material type

- Thermal conductivity

- Reflective properties

Metals handle heat in different ways. Aluminum bounces more laser light than steel. So, you need to change the laser settings for a good cut. Copper and brass also reflect a lot of light. You must use special settings for these metals. If a metal moves heat quickly, cutting gets harder.

Tip: Always check how much the material absorbs and reflects light. This helps you pick the best settings for your job.

Assist Gas Choice

The gas you use can change how well you cut. Each gas has its own good points. Here is a table to help you pick the right gas:

| Gas Type | Used For | Purpose |

|---|---|---|

| Nitrogen (N2) | Stainless steel, aluminum, galvanized steel | Makes clean cuts with no oxidation. |

| Oxygen (O2) | Mild steel, carbon steel | Helps cut thicker steel faster. |

| Compressed Air | Mild steel, stainless steel, aluminum (thin sheets) | Saves money and works for general cutting. |

The gas you pick also changes the edge and how thick you can cut. Oxygen lets you cut thick carbon steel fast, but the edges may be rough. Nitrogen gives smooth, shiny edges for stainless steel and aluminum. Compressed air is good for thin sheets and costs less.

Cutting Speed and Settings

You need to set the power and speed just right. To cut thick metal, use more power and slow down. This gives the laser more time to cut. For thin metal, you can go faster and save time.

| Setting Type | Recommendation |

|---|---|

| Power for Thicker | Use more power to cut thick metal well. |

| Speed for Thicker | Go slower so the laser can cut cleanly. |

| Speed for Thinner | Go faster to work quickly and keep quality. |

Note: Always test your settings on scrap metal before you start your main job.

Machine Condition

Your laser machine needs to be in good shape. Clean lenses and mirrors help the laser stay strong. Dirty or worn parts can make cuts worse. Take care of your machine to keep it working well. Check for dust and broken parts before each job. A clean, working machine helps you cut thicker metal safely.

Optimizing 3000W Fiber Laser Performance

Recommended Settings

To get the best results when cutting thick materials, you need to adjust your settings for each type of metal. Here are some practical tips:

- Change the laser power and cutting speed for each material. Thicker metals need more power and a slower speed.

- Pick the right assist gas. Oxygen works well for carbon steel and gives black edges. Nitrogen keeps stainless steel and aluminum edges bright and clean.

- Adjust the focus position based on the material and its thickness. This helps you get a smooth and precise cut.

Tip: Always test your settings on a small piece before starting your main project.

Quality at Maximum Thickness

When you use a 3000W fiber laser at its maximum thickness, you may notice some quality issues. Watch for these common problems:

- The cut quality can get worse over time if you do not clean the lens.

- Heat from the laser can cause the metal to expand, which affects the cut.

- The laser head needs proper calibration to keep cuts straight and even.

- You may see more burrs or rough edges as you cut thicker materials.

To improve your results:

- Use the right assist gas to reduce roughness and slag.

- Increase the laser power and slow down the speed for thick materials.

- Make sure the laser beam is focused correctly.

- Keep your machine clean and check it often.

- Try cutting in layers for very thick pieces.

Safety Tips

Cutting thick metal with a 3000W fiber laser can be dangerous. Follow these safety steps:

- Always follow the rules for using your equipment.

- Keep fire extinguishers nearby.

- Treat the laser area as a danger zone.

- Never use the machine if you feel tired or have been drinking.

- Wear goggles to protect your eyes.

- Use dust masks to protect your lungs.

You should also use an enclosure to keep fumes inside and wear certified laser goggles. Make sure you have good ventilation and check your machine for problems. Learn about the materials you cut to avoid toxic fumes or fire hazards. Regular maintenance helps prevent electrical and mechanical risks.

Note: Facilities that use safety controls have fewer laser accidents. Always put safety first.

You can cut carbon steel up to 20mm, stainless steel up to 10mm, and aluminum up to 8mm with a 3000W fiber laser. To get the best results, adjust power, speed, and assist gas for each job. Check the table below for key settings:

| Factor | Tip |

|---|---|

| Power Levels | Increase for thicker materials |

| Cutting Speed | Slow down for clean cuts |

| Assist Gas Type | Match gas to material |

Stay safe by wearing protective gear and keeping your workspace clean. Inspect your machine often and use high-purity gases for better cuts.

FAQ

How fast can you cut thick metal with a 3000W fiber laser?

Cutting speed depends on the metal and its thickness. For example, you can cut 10mm carbon steel at about 0.8–1.2 meters per minute. Thicker metal needs slower speed for a clean cut.

What happens if you try to cut thicker than the recommended limit?

You may see rough edges, more burrs, or incomplete cuts. The laser might not cut through the material. Always follow the recommended thickness for best results.

Do you need special training to use a 3000W fiber laser?

Yes. You should learn how to set up the machine, adjust settings, and follow safety rules. Training helps you avoid mistakes and keeps you safe.

Can you cut other metals like copper or brass with a 3000W fiber laser?

You can cut copper and brass, but these metals reflect more laser light. You need special settings and extra care. Always check your machine’s manual before cutting these materials.

Can laser welding produce strong welds with a laser welding machine?

How to Boost Laser Welding Strength for Better Results