Laser beam welding and electron beam welding create the smallest heat affected zone of welding process. This is important because a small heat affected zone of welding process keeps parts and sensitive pieces safe from harm. Many experts say that controlling energy in the heat affected zone of welding process keeps the area near the weld strong.

- A small heat affected zone of welding process lowers the chance of softening and breaking.

- Jobs like aerospace and pipeline building often need this kind of careful work with the heat affected zone of welding process for the best results.

Key Takeaways

- Laser and electron beam welding make very small heat affected zones. This keeps the metal close by strong and safe.

- A smaller heat affected zone lowers the chance of cracks and brittleness. This is good for things like airplanes and medical tools.

- It is important to control heat during welding. Using faster speeds and less power keeps the heat affected zone small.

- Pick the right welding process for the metal type and thickness. This helps make welds that are strong and last a long time.

- Always test your welding settings on scrap metal first. This helps you get the best results and protects your final piece.

Heat Affected Zone of Welding Process

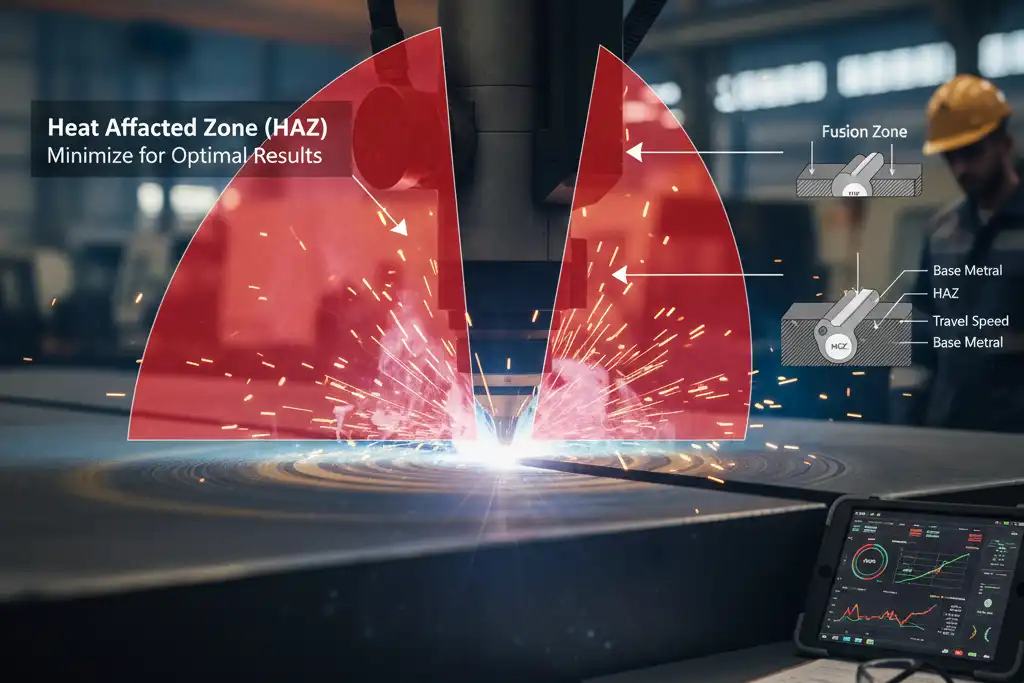

What is a Heat Affected Zone?

When you weld metal, the area next to the weld changes because of the heat. This area is called the heat affected zone of welding process. It does not melt, but the heat makes the metal’s structure and properties different. The heat affected zone of welding process starts at the edge of the weld and stretches out until the metal cools enough that its properties stay the same. Welding engineers say this zone is important because it can change how strong or tough the metal is.

Why HAZ Size Matters

You need to pay attention to the size of the heat affected zone of welding process. A smaller zone means less change to the metal. This helps keep the welded part strong and safe. If the zone is too big, the metal can become brittle or weak. You might see problems like cracks or rust if the zone is not controlled.

Tip: Choosing a welding process that creates a small heat affected zone of welding process helps protect your parts from damage.

Here is a table that shows how the size of the heat affected zone affects different properties of the metal:

| Property | Impact of HAZ Size |

|---|---|

| Strength and Hardness | Areas close to the weld may get harder and more brittle. |

| Toughness | Toughness can drop, making the metal less able to handle impacts. |

| Corrosion Resistance | Changes in the metal can make it rust more easily, especially in stainless steel. |

You can also look at the microstructure in the heat affected zone:

- Fine grains in the zone can make the metal tougher.

- Large, coarse grains can make the metal weaker and easier to break.

When you pick a welding process, think about how it will affect the heat affected zone of welding process. This helps you get a strong, safe weld every time.

Welding Processes and HAZ Comparison

TIG, MIG, and Stick Welding

You often see TIG, MIG, and stick welding in workshops and factories. These methods use electric arcs to melt metal and join pieces together. When you use TIG welding, the heat input can change the size of the heat affected zone of welding process. If you increase the heat, the zone gets bigger. This happens because high temperatures and longer welding times let the metal grains grow larger. Bigger grains make the area near the weld weaker. You may notice that the heat affected zone of welding process in TIG, MIG, and stick welding is wider than in advanced methods. The joint can lose strength and toughness if you do not control the heat.

Note: The TIG-MIG hybrid joint creates an even larger heat affected zone compared to using TIG or MIG alone.

Laser Beam Welding

Laser beam welding uses a focused laser to melt and join metals. You can control the heat input very precisely by adjusting the travel speed and beam settings. If you move the laser quickly, you reduce the heat input per inch, which keeps the heat affected zone of welding process small. This is important when you work with thin or heat-sensitive materials. You avoid overheating and lower the risk of damage. Advanced laser techniques, like beam modulation and wobble, help you manage the thermal profile and prevent stress in the metal.

- Laser welding is a top choice for joining delicate parts.

- You get clean welds with minimal change to the surrounding metal.

- The IPG LightWELD Laser Welder produces a smaller heat affected zone than traditional MIG and TIG welders.

Electron Beam Welding

Electron beam welding uses a beam of electrons in a vacuum to melt and join metals. The vacuum lets the beam stay tightly focused, so you heat only a small area. You create a molten pool while the rest of the metal stays solid. This makes the heat affected zone of welding process very narrow. For example, when you weld Inconel 718 sheets, the zone can be as small as 1.5 mm or even just 100 micrometers in some cases. You also get rapid cooling, which helps prevent warping and cracking. The small zone keeps the metal strong and reduces distortion.

- The vacuum environment helps you keep tight tolerances.

- Low heat input and fast cooling shrink the heat affected zone.

- You avoid problems like warping and loss of strength.

HAZ Size Comparison Table

Here is a simple table to help you compare the heat affected zone sizes for each welding process:

| Welding Process | Typical HAZ Size | Suitability for Heat-Sensitive Materials |

|---|---|---|

| TIG/MIG/Stick | Large | Less suitable |

| Laser Beam Welding | Small | Very suitable |

| Electron Beam Welding | Smallest | Best choice |

Tip: If you need the smallest heat affected zone of welding process, choose laser or electron beam welding.

Why Laser and Electron Beam Welding Minimize HAZ

Technical Reasons for Small HAZ

Laser and electron beam welding focus energy on a tiny spot. This melts the metal fast and only in a small area. You can change the power for thin or thick metal. Thin metal needs less power, so it does not melt too much. Thick metal needs more power to make a strong weld.

Fast welding speeds keep the heat low. When you move the laser or beam quickly, the metal heats and cools in seconds. This stops the heat from spreading far. You get a narrow weld and a small heat affected zone of welding process. The metal near the weld stays strong and keeps its structure.

- Use high power for thick metal and low power for thin metal.

- Fast welding keeps the heat affected zone small.

- Electron beam welding makes deep, narrow welds.

- Laser welding uses a small beam for deep welds and less heat spread.

- Fast cooling helps the metal stay strong, but it can get brittle.

Tip: If you need to weld near heat-sensitive parts, pick a process that lets you control the heat well.

Process Advantages

Laser and electron beam welding have many benefits for a small heat affected zone and good welds. You can join metals that melt at different temperatures. The focused energy melts only what you need, so nearby parts stay safe. You also get less shrinking and bending, which is good for careful work.

Here is a table that shows how these methods compare for heat-affected zone control and weld quality:

| Welding Method | Heat-Affected Zone Control | Weld Quality |

|---|---|---|

| Laser Beam Welding | Smaller heat-affected zone due to rapid heating | High-quality welds with minimal defects |

| Electron Beam Welding | Tight heat-affected area allows for dissimilar materials | Compact, vacuum-tight welds with precise control |

You can also look at how fast they work and how many defects happen:

| Feature | Laser Welding | Electron Beam Welding |

|---|---|---|

| Speed | High speed, good for small HAZ | Slower because of vacuum |

| Heat Affected Zone (HAZ) | Very small HAZ | Bigger HAZ from deep welds |

| Defect Rates | More likely to have porosity | Fewer defects, but setup is harder |

| Penetration Depth | Up to 20 mm in steel | Up to 200 mm in steel and aluminum |

| Production Complexity | Easier to set up | Harder because of vacuum |

- You can weld thin or thick metal with high accuracy.

- You get strong welds, even with metals that do not mix well.

- You avoid cracks and bending because you control the heat.

- Electron beam welding is best for vacuum-tight and strong joints.

- Laser welding is faster and easier for many jobs.

Note: Both methods help keep the heat affected zone small. This protects your parts and makes the final product better.

Applications for Minimal HAZ Welding

Material and Thickness Considerations

You should think about what kind of metal you have and how thick it is before picking a welding process with a small heat affected zone (HAZ). Laser welding works best on thin metals, usually less than 3mm thick. This method is very accurate and keeps the HAZ tiny. It is good for jobs that need exact measurements, like electronics or medical tools. Metals that move heat fast, like structural steel, also do better with welding that keeps the HAZ small.

- Laser welding works great for thin metals when you want to stop warping.

- The HAZ is much smaller with laser welding than with MIG welding.

- If your metal spreads heat fast, the area near the weld changes even less.

The thickness of your metal changes how the HAZ looks. Here is a table that shows how thin and thick metals act with different welding:

| Aspect | Thin Materials | Thick Materials |

|---|---|---|

| Heat Input | Lower heat input, narrower HAZ | Higher heat input, wider HAZ |

| Cooling Rates | Fast cooling, harder microstructure | Slow cooling, softer HAZ |

| Microstructural Change | Narrow zone, less grain growth | Wider zone, more tempered structure |

If you use too much heat on thin metal, the HAZ gets too wide. This can make your part weaker and less bendy. If the metal has to hold a lot of weight or pressure, a big HAZ can make it break easier.

Industry Uses

Lots of industries need welding with a small HAZ to keep parts strong and exact. You see this in aerospace, where every part must stay just as strong as before. Gas turbines use these methods for parts that need careful HAZ control. Oil and gas companies use small HAZ welding for tools that go deep underground, where the metal must be tough.

| Industry | Typical Applications |

|---|---|

| Aerospace | Components where original material properties are critical |

| Industrial Gas Turbines | Parts needing precise HAZ control |

| Oil & Gas | Downhole tools and equipment |

Laser welding is also used in electronics, medical tools, and making cars. For example:

- Jewelers use laser welding to make custom jewelry and fix tiny art without hurting the rest.

- Car shops use it to fix strong steel and aluminum, making careful repairs with little heat change.

- Medical device makers use laser welding to seal pacemakers and join tiny, delicate parts.

Tip: If you need to join different metals or protect sensitive parts, pick a welding process that keeps the HAZ as small as possible.

HAZ Size Comparison Table

When you choose a welding process, you want to know how much heat will affect your metal. The heat affected zone (HAZ) size can change the strength and quality of your weld. You can use the table below to compare the typical HAZ sizes for common welding methods. This helps you pick the best process for your project.

| Welding Process | Typical HAZ Width | Weld Appearance | Best Use Case |

|---|---|---|---|

| Stick (SMAW) | 3–8 mm | Wide, visible | General repairs, construction |

| MIG (GMAW) | 2–6 mm | Medium, clean | Automotive, fabrication |

| TIG (GTAW) | 1–4 mm | Narrow, neat | Precision, thin metals |

| Laser Beam Welding | 0.2–1 mm | Very narrow, smooth | Electronics, medical, jewelry |

| Electron Beam Welding | 0.1–0.8 mm | Ultra-narrow, precise | Aerospace, high-tech parts |

Tip: If you need to protect sensitive parts or want the strongest weld, choose a process with the smallest HAZ, like laser or electron beam welding.

You should know that these numbers can change. The type of metal you use, how thick it is, and the settings on your welding machine all play a part. For example, stainless steel and aluminum react differently to heat. If you use more power or weld slower, the HAZ gets bigger. If you use less power or move faster, the HAZ stays small.

The strength of the HAZ depends on more than just the welding process. The grade of your base material, the way it was made, and even the type of electrode you use can change how the HAZ acts. You might see big differences in the HAZ if you switch materials or change your welding settings.

- Always check your material type before you start welding.

- Adjust your welding speed and power to control the HAZ.

- Use the table as a guide, but test on your own parts for the best results.

A small HAZ keeps your metal strong and helps you avoid problems like cracks or rust. When you understand how each process affects the HAZ, you make better choices for your project.

Laser and electron beam welding make the smallest heat affected zones. Electron beam welding makes a thin fusion zone and cools fast. This means the metal does not bend much or change inside. When you choose a welding process, think about your metal type and how thick it is. You should also think about what your project needs. The heat affected zone is usually the weakest spot in a weld. You can stop problems like grain growth, hard spots, or soft spots by picking the right welding method.

- Always pick a welding process that fits your metal and job.

- A smaller heat affected zone gives you stronger, safer welds for parts that do not like heat.

FAQ

What is the main benefit of a small heat affected zone?

A small heat affected zone keeps your metal strong and reduces the risk of cracks or warping. You protect the area near the weld from damage.

Can you use laser welding on all metals?

You can use laser welding on many metals, like steel, aluminum, and titanium. Some metals may need special settings or preparation for the best results.

Why does electron beam welding need a vacuum?

Electron beam welding needs a vacuum to keep the electron beam focused. The vacuum lets you make precise, deep welds with a very small heat affected zone.

How do you control the size of the heat affected zone?

You control the heat affected zone by adjusting welding speed, power, and technique. Faster welding and lower heat input make the zone smaller.

Tip: Test your settings on scrap pieces before welding your final part.

What is the heat affected zone in laser welding

Which welding process has the smallest heat affected zone?