You will often see the Heat Affected Zone width for steel welding is between 2 and 4 millimeters. This is about 0.08 to 0.16 inches. The average width is around 3.2 millimeters, or 0.13 inches. This range works for many steel types and thicknesses. Sometimes, the zone can be smaller, like 1.0 mm, 1.5 mm, or 2.0 mm. The welding method can change the size. Many things affect the width, like heat input, temperature changes, and steel type. Knowing these things helps you make better welds.

Key Takeaways

- The average width of the Heat Affected Zone in steel welding is about 3.2 mm. It usually ranges from 2 to 4 mm. Different welding methods change the HAZ width. MIG welding makes a wider zone. TIG welding keeps the zone narrow. This is good for high-quality welds. You can control HAZ width by changing heat input and welding speed. Using less heat or welding faster makes a smaller HAZ. A wide HAZ can make steel weaker. This can cause cracks and failures. A narrow HAZ makes the weld stronger and last longer. Laser welding makes the smallest HAZ. It gives better control and less bending. This makes it great for careful, detailed work.

Heat Affected Zone Width in Steel

What is HAZ Width

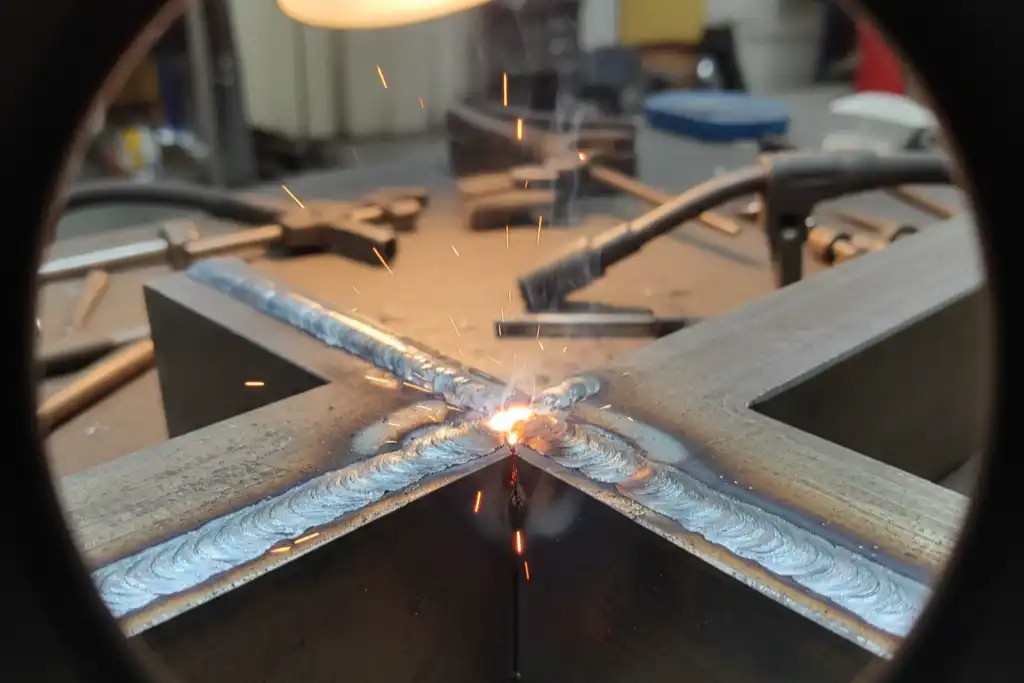

You may wonder what the Heat Affected Zone means in steel welding. The Heat Affected Zone is the part of the steel next to the weld that does not melt but still changes because of the heat. This area stays solid, but its structure and properties shift due to the high temperatures from welding. The width of this zone depends on how much heat you use and how the steel reacts to that heat. You can find different structures inside the Heat Affected Zone. Some parts may look coarse or grainy. These coarse-grained sections are often the weakest and can fail more easily than other parts of the weld.

Note: The Heat Affected Zone is not the same as the weld itself. It is the area around the weld that feels the heat but does not melt.

Scientific studies show that the Heat Affected Zone can have a width between 2 mm and 4 mm in most cases. One study found an average width of 3.2 mm. In some special welding conditions, the zone can be much wider, even up to 15 mm. The Heat Affected Zone is always present in steel welding, but its size can change based on the process and settings you use.

Measuring the Heat Affected Zone

You can measure the width of the Heat Affected Zone in several ways. Some methods use simple rules, while others use advanced tools or experiments. Here is a table that shows the most common ways to measure the Heat Affected Zone in steel welds:

| Method | Description |

|---|---|

| Empirical Formulas | A rule of thumb suggests that HAZ width is typically 1.5 to 3 times the molten pool width. |

| Finite Element Analysis | This method uses simulations to model heat transfer, predicting HAZ with up to 5% accuracy. |

| Thermal Modeling Techniques | Combines heat transfer principles with welding simulation to visualize heat flow and predict HAZ size. |

| Experimental Measurements | Involves actual testing, using techniques like metallography to observe microstructure changes. |

You can use simple formulas if you want a quick estimate. For more exact results, you might use computer models or test samples in a lab. Metallography is a common lab method. It lets you see the changes in the steel under a microscope. Each method gives you a different level of detail and accuracy.

Tip: If you need to know the exact width of the Heat Affected Zone for your project, use experimental measurements or computer modeling for the best results.

HAZ Widths by Welding Process

MIG Welding

When you use MIG welding for steel, you create a wider Heat Affected Zone. MIG welding works fast and uses high heat. This speed and heat cause the area around the weld to change more. You may notice that the microstructure of the steel shifts, which can affect the strength of your weld. MIG welding is common for large projects, but you should know that the HAZ can be larger than with other methods.

- MIG welding produces a larger HAZ because of its fast weld speeds.

- The wider HAZ can change the steel’s properties near the weld.

TIG Welding

TIG welding gives you more control over the heat. You can make precise welds with less heat input. This means the Heat Affected Zone stays narrow. If you want high-quality welds, TIG welding is a good choice. You can keep the steel’s structure close to the weld strong and stable.

- TIG welding offers precise heat control, resulting in a narrower HAZ.

- The difference in HAZ width between TIG and MIG welding is important for projects needing strong, clean welds.

Stick Welding

Stick welding uses a simple process. You may see a moderate Heat Affected Zone with this method. The heat input is not as high as MIG welding, but it is not as controlled as TIG welding. The HAZ width often falls between the sizes seen in MIG and TIG welding. Stick welding works well for repairs and outdoor jobs.

- Stick welding creates a moderate HAZ width.

- The HAZ is usually wider than TIG but narrower than MIG.

Laser Welding

Laser welding uses a focused beam of light. You get a very small Heat Affected Zone because the heat input is low and the cooling is fast. The laser targets a tiny spot, so the steel around the weld does not change much. You can see the effects of different laser settings in the table below.

| Parameter | Effect on HAZ Width |

|---|---|

| Higher heating rate | Decreases subzone widths in the HAZ |

| Laser power | Directly affects HAZ width |

| Focal point position | Influences HAZ width |

| Increased heat input | Increases HAZ width |

| Non-isothermal temperature | Changes microstructure in the HAZ |

- Laser welding limits the HAZ because rapid cooling prevents annealing.

- The heat input is much lower than in traditional welding, so the HAZ stays small.

- The focused laser beam keeps the heat local, reducing warping and distortion.

Tip: If you want the smallest Heat Affected Zone, laser welding is the best option.

Factors Affecting HAZ Width

Heat Input and Welding Parameters

You can control the width of the Heat Affected Zone by adjusting heat input and welding settings. When you use more heat during welding, the zone around the weld gets wider. Recent research shows that higher heat input leads to a larger Heat Affected Zone. This happens because the steel cools more slowly, which makes the grains inside the metal grow bigger. Bigger grains can make the steel weaker and less tough.

You can change the welding parameters to affect the HAZ width. Here is how each setting works:

- Increasing welding current gives you deeper penetration and more reinforcement, but the width of the weld does not change much.

- Higher arc voltage adds more heat, which makes the weld wider and reduces penetration a little.

- Faster welding speed makes the weld and HAZ narrower, and it also lowers penetration and reinforcement.

Tip: If you want a smaller Heat Affected Zone, try lowering the heat input or increasing your welding speed.

Steel Type and Thickness

The type of steel you use changes the size and properties of the Heat Affected Zone. Different steels react to heat in different ways. Some steels need careful control to avoid problems like brittleness or distortion. You can see the differences in the table below:

| Steel Type | Thermal Conductivity | HAZ Characteristics |

|---|---|---|

| Ferritic Stainless | Higher | Needs careful welding to prevent distortion and brittle HAZ |

| Austenitic Stainless | Lower | Can become harder and less tough in the HAZ |

Thicker steel takes longer to heat and cool, so the Heat Affected Zone can be wider. Thin steel cools quickly, which keeps the HAZ narrow. You should always check the steel type and thickness before you start welding. This helps you choose the right settings and avoid problems with the weld.

Why HAZ Width Matters

Weld Quality and Performance

You need to understand why the width of the Heat Affected Zone is important for weld quality. The area next to the weld changes when you apply heat. These changes can make the steel weaker or stronger. If you control the size of this zone, you help keep the weld strong and safe. The Heat Affected Zone often becomes a weak point in welded joints. You want to avoid problems like cracking or loss of strength.

Managing the width of the Heat Affected Zone helps you create strong bonds between metals. You protect the integrity of the weld and make sure the steel can handle heavy loads.

Here are some reasons why controlling HAZ width matters for weld quality:

- You keep the steel’s structure stable near the weld.

- You reduce the risk of defects like cracks or warping.

- You improve the strength and durability of the welded joint.

Mechanical Properties and Issues

The Heat Affected Zone changes the mechanical properties of steel. When the zone gets too wide, you may see problems like reduced strength and toughness. The steel can become more likely to crack or bend. High temperatures in the HAZ cause the metal’s structure to shift. This can lead to issues such as hydrogen embrittlement or corrosion.

The table below shows what happens to mechanical properties in the HAZ:

| Mechanical Property | Change in HAZ |

|---|---|

| Hardness | Increased |

| Ductility | Decreased |

| Toughness | Decreased |

| Susceptibility to Cracking | Increased |

If you let the HAZ get too wide, you risk making the steel weaker. You may see more distortion and less resistance to repeated stress. Microstructural changes in the HAZ can also make the steel less tough. In some steels, a soft zone can form, which may fail early under heavy loads.

Tip: Always pay attention to the width of the Heat Affected Zone. You protect your welds from defects and keep your steel structures safe.

You now know that the average width of the heat affected zone in steel welding is about 3.2 mm, with most cases falling between 2 and 4 mm. Keeping the HAZ narrow helps you protect the steel’s strength and quality. A 2019 study showed that over 60% of pressure vessel weld failures started in the HAZ, not the weld itself.

- Minimizing the HAZ reduces stresses and chemical changes in steel.

- A wide HAZ can weaken the material and increase the risk of failure.

Always think about HAZ width when you choose your welding method and settings.

FAQ

What is the heat affected zone in steel welding?

You see the heat affected zone as the area next to the weld that changes because of heat. The metal does not melt, but its structure and properties shift. This zone can affect the strength of your weld.

What factors change the width of the heat affected zone?

You control the width by adjusting heat input, welding speed, and steel type. Higher heat input makes the zone wider. Faster welding keeps it narrow. Different steels react in unique ways.

What problems can a wide heat affected zone cause?

A wide heat affected zone can make steel weaker. You may see more cracks, warping, or loss of toughness. Keeping the zone narrow helps you avoid these issues and improves weld quality.

What welding process gives you the smallest heat affected zone?

Laser welding gives you the smallest heat affected zone. The focused beam heats a tiny spot, so the area around the weld stays strong. You get less distortion and better control.

What is the best way to measure the heat affected zone width?

You can use metallography to see changes under a microscope. Computer models and simple formulas also help you estimate the width. For exact results, lab testing works best.

How to Narrow the Heat-Affected Zone in Welding Processes

Which welding process has the smallest heat affected zone?

What you should know about CNC machine tools and laser cutting