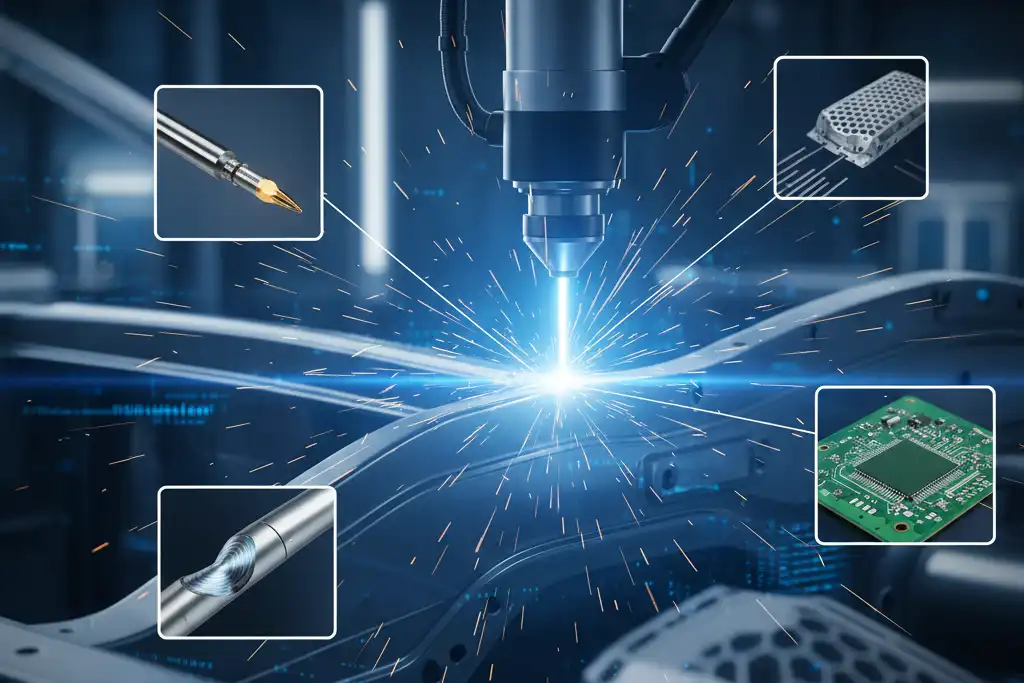

Laser welding uses a strong laser beam to join metal pieces. You can find this technology in cars, planes, electronics, medical tools, and making computer chips. The process works well with metals like stainless steel, nickel, and titanium.

Laser welding gives very exact results, works quickly, and does not heat up the metal much. You can make welds as thin as 0.2 mm wide. It can finish jobs up to 50% faster than older ways. Many companies pick laser welding because it causes less bending and is good for thin metals.

| Metric | Value |

|---|---|

| Market Value (2025) | USD 2.9 billion |

| Market Forecast (2035) | USD 4.2 billion |

| Growth Rate | 3.7% CAGR |

Laser welding is taking the place of older welding methods. It is being used more in factories.

Key Takeaways

- Laser welding is used in many fields like cars, planes, electronics, and medical tools because it is fast and accurate.

- This way of welding makes thin welds and uses less heat, so it does not hurt fragile parts.

- Laser welding works much faster than old ways. It can finish jobs up to ten times quicker. This helps factories make more things in less time.

- It makes clean and strong welds with less bending or warping. This means there is less fixing needed after welding.

- Safety matters a lot. Always wear safety gear and follow training rules when you use laser welding machines.

Laser welding applications

Industrial uses

Laser welding is used in many big industries. It helps join parts in cars and planes. You also see it in electronics and medical devices. Laser welding makes strong and exact connections. It works well with metals like stainless steel and aluminum. Titanium, copper, and special alloys also work. Laser welding fits many shapes and sizes. You can use it for small sensors. You can use it for large engine parts too.

Laser welding is very precise and fast. You can weld thin metals easily. It does not make much heat or bend the metal. This is good for delicate parts.

Here is a table that shows how industries use laser welding:

| Industrial Sector | Main Applications |

|---|---|

| Medical Device Fabrication | Making surgical tools and implant devices. Also used for medical equipment with tiny shapes. |

| Semiconductor Industry | Used for putting together chip packages and sensors. Also for magnet parts in microchip work. |

| Automotive Industry | Used for joining car body panels and exhausts. Also for fuel tanks and batteries in electric cars. |

| Aerospace Engineering | Used for making turbine blades and engine parts. Also for fuselage sections with little bending. |

| Electronics Manufacturing | Used for joining tiny electronic parts. Also for sealing cases in small devices. |

Laser welding works with many metals and alloys. You can use it for stainless steel and aluminum. It also works for titanium and copper. This helps solve many problems in factories.

Metal furniture and appliances

Laser welding is used to make metal furniture and home appliances. It helps make strong and smooth joints. You get a nice finish and better strength. Laser welding works with many types of aluminum, such as:

- Aluminum 1100: Pure aluminum that does not rust easily.

- Aluminum 3003: Stronger than 1100, used for cooking tools.

- Aluminum 5052: Easy to shape and does not rust.

- Aluminum 6061: Welds well and is used a lot.

- Aluminum 7075: Very strong but hard to weld.

When making appliances, laser welding helps you:

- Put together fridge parts with tight seals to stop leaks.

- Make strong joints in washing machine drums for better work.

- Make oven parts that do not rust and stay strong.

For metal furniture, you get:

- Strong and smooth joints that look nice and last long.

- You can make fancy shapes and patterns for new designs.

- You can weld metal close to other materials without harm.

Laser welding is much faster than old ways. You can finish jobs up to ten times quicker. The welds are clean and strong. You do not need much extra work after welding.

Electronics and medical devices

Laser welding is used in making electronics and medical devices. It gives very exact welds for small and delicate parts. You can join different materials, like metals and some plastics.

In electronics, laser welding is used for:

- Soldering parts onto chips and circuit boards.

- Connecting battery tabs and cases for phones and electric cars.

- Lining up parts in LEDs and fiber optics.

In medical devices, laser welding helps you:

- Make strong joins in catheters and surgical tools.

- Keep sensitive materials safe from heat.

- Seal devices like pacemakers to keep out dirt.

- Make things faster and save time in factories.

You must follow strict rules when using laser welding here. ISO 15609-4 and ISO 13919 set rules for weld quality. You need to test welds with special methods. You also use process control to keep quality high. For medical devices, you must meet FDA 820.75 and ISO 13485 rules.

Jewelry and tool making

Laser welding changes how you make and fix jewelry and tools. You can make tiny welds without hurting gems or small parts. This way, you can add fine engravings and textures. You can put together tricky pieces with good strength.

Here are ways laser welding is used in jewelry and tool making:

- Fill small gaps in metal to make it stronger.

- Fix prong settings without taking out stones.

- Repair ring settings and resize rings safely.

- Fix problems and add fine engravings.

- Make new designs quickly for custom pieces.

- Fix chains and joins without hurting nearby parts.

Laser welding gives you great precision. You get clean and strong welds with little heat. This keeps stones like pearls and opals safe. The weld cools fast, so your jewelry keeps its shape and looks nice.

Laser welding works with many metals and alloys. You can use it for gold, silver, platinum, and stainless steel. This helps you make special designs and fix valuable items easily.

Laser welding advantages

High precision and quality

Laser welding makes very exact welds. The focused beam lets you control the weld size. You can join tiny parts without mistakes. Many industries need this accuracy. Medical devices and electronics need it most.

Take a look at this table. It shows how well laser welding works:

| Metric | Value |

|---|---|

| Accuracy | 0.981 |

| F1-score | 0.961 |

| AUROC | 0.997 |

The numbers are very high. This means welds are strong and clean. Medical devices need tolerances under 10 micrometers. Car batteries can have defect rates as low as 0.2 parts per million. These results show why laser welding is trusted for important jobs.

Tip: Laser welding helps you make parts that fit together perfectly. This helps you avoid problems later.

Speed and efficiency

Laser welding is much faster than older ways. You can finish jobs quickly and make more products. The process works well on automated lines.

- Laser welding can be 2–10 times faster than arc welding.

- Production lines can run 3–5 times faster than with old welding.

- One laser welding system can be 4–5 times faster than TIG or MIG welding.

Manufacturers see big gains in efficiency with laser welding. Here is a table that shows some benefits:

| Benefit | Description |

|---|---|

| Minimized material waste | Precise welding uses less extra material. |

| Lower energy requirements | Advanced lasers use less energy and work fast. |

| Cleaner processes | Fewer supplies mean less pollution and waste. |

You save money because you need less space and fewer repairs. You can check each weld for quality while working. This helps you catch problems early.

Minimal heat impact

Laser welding uses a focused beam to heat a small area. This makes a smaller heat-affected zone than older methods. You get less damage and keep the metal strong.

- Minimal heat input makes a smaller heat-affected zone.

- You avoid warping, cracking, or weakening thin materials.

- This is important for medical devices and electronics.

You can weld close to other materials without hurting them. The process keeps the metal’s properties safe. Your finished product works as it should.

Reduced distortion and post-processing

Laser welding helps you avoid bending and warping. The focused energy and fast speed mean less heat spreads. You get fewer stresses and less expansion.

- Focused energy and high speed lower distortion.

- Tight heat control means less extra work after welding.

- Faster cooling lowers stress.

You do not need much post-processing. This saves time and money. Companies report up to 35% higher assembly line efficiency with laser welding. A 1.5 kW laser welding machine can save up to $3 per meter compared to TIG welding.

Note: You spend less time fixing problems and more time making products. Laser welding helps you keep costs low and quality high.

Comparison with traditional welding

Key differences

Laser welding and traditional welding are not the same. Laser welding uses a focused beam to join metals. MIG and TIG welding use electric arcs instead. Laser welding works quickly and makes tight seams. The welds are clean and use less heat. MIG welding is good for thick materials and makes strong welds. TIG welding gives you lots of control for small parts.

Here is a table that shows the main features:

| Welding Technique | Key Features | Best Applications |

|---|---|---|

| Laser Welding | Minimal heat input, tight seams, low distortion, clean welds, fast cycle times | Stainless steel panels, consumer products, precision assemblies |

| MIG Welding | Suitable for thicker materials, strong welds, fast deposition | Brackets, frames, high-volume production |

| TIG Welding | Highest control, cleanest arc, ideal for delicate parts | Aerospace components, visible parts requiring high quality |

Laser welding is known for being fast and precise. You can make tiny weld spots under 0.1 mm. The heat-affected zone is small. Traditional welding needs more skill to be accurate. It is slower and makes more heat.

| Aspect | Laser Welding | Traditional Welding |

|---|---|---|

| Precision | Extremely high; can reach <0.1 mm spots | Moderate to low; depends on operator skill |

| Heat Affected Zone | Small | Large |

| Speed | Extremely fast | Moderate to slow |

Laser welding works best for thin and medium-thickness materials. Laser machines cost more money. You need special safety steps. You must wear laser safety glasses and work in safe areas.

Where laser welding excels

Laser welding is best when you need high precision. It is good for jobs with tight designs and small spaces. You get clean and strong joints with little bending. Laser welding helps you work faster and make better products.

Laser welding is better than old methods in these places:

- Automotive manufacturing

- Aerospace engineering

- Electronics assembly

You can weld tiny parts without hurting them. Laser welding is great for medical devices, sensors, and battery packs. You save time and do less extra work. You also avoid bending and keep materials strong.

Tip: Laser welding helps you meet strict quality rules in jobs where every detail matters.

Laser welding has some limits. The machines cost a lot. You need trained workers. It works best for thin materials. You must follow safety rules to protect your eyes and skin from the laser.

| Limitation | Description |

|---|---|

| Cost | Equipment is expensive to buy and maintain |

| Safety Hazards | High-power lasers can cause burns and eye injuries |

| Surface Sensitivity | Weld quality depends on clean surfaces |

| Material Thickness | Best for thin to medium materials |

| Operator Skill | Requires special training |

You should always wear safety gear and get training when using laser welding systems.

Laser welding is used in many fields like cars and medical tools. It helps make things with great accuracy and strong joins. It also works fast. The market is getting bigger as machines get smarter.

| Trend | Description |

|---|---|

| Increased Precision | Needed for aerospace and automotive |

| Faster Production Times | Improves efficiency |

| Cost Savings | Reduces waste and labor |

| Market Growth | USD 26.56 billion by 2025 |

- New laser welding uses robots and checks work as it happens.

- This means you get better products and help the environment.

Laser welding will keep changing how people make things in the future.

FAQ

What materials can you weld with a laser?

You can weld stainless steel, aluminum, titanium, copper, and nickel. Many alloys work too. Laser welding is best for thin and medium metals. Clean the surface before you start. This helps you get better welds.

Is laser welding safe for you to use?

You need to wear laser safety glasses. Always follow safety rules. Lasers can burn your skin or hurt your eyes. Work in a safe place. Get proper training before you use lasers.

How does laser welding compare to TIG and MIG welding?

| Feature | Laser Welding | TIG/MIG Welding |

|---|---|---|

| Speed | Faster | Slower |

| Precision | Higher | Moderate |

| Heat Impact | Lower | Higher |

Laser welding makes cleaner welds. You get less bending in the metal.

Can you use laser welding for jewelry repair?

You can use laser welding to fix jewelry. It lets you repair tiny parts. You do not damage stones or delicate settings. The joins are strong and clean. Your jewelry keeps its original look.

Fiber Laser Welding Versus CO2 Laser Welding—A Detailed Comparison

What Should Beginners Understand About Laser Welding

How to Remove Rust from Metal: 11 Different Methods

How to determine if a laser cleaning machine is worth buying