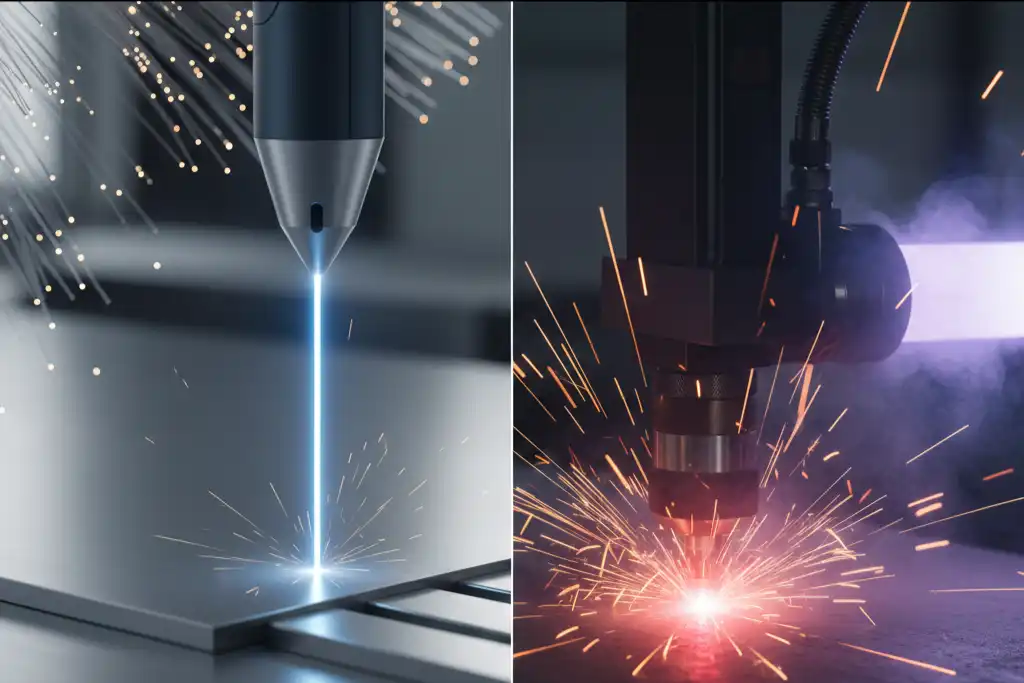

You can see big differences between fiber laser welding and CO2 laser welding. Fiber lasers give better accuracy, a stronger beam, and use up to 42% less energy. Many industries like cars, electronics, and airplanes now choose fiber lasers. They do this because fiber lasers lower mistakes and cost less to fix.

- Fiber laser welding is the top choice in 2024 and saves 25-30% more energy than CO2 lasers.

- CO2 lasers need more repairs and cost more to run.

Knowing these differences helps you pick the right technology for your job.

Key Takeaways

- Fiber laser welding works better. It uses up to 42% less energy than CO2 lasers. This saves money. It also helps the environment.

- Pick fiber lasers for metals and jobs needing high precision. They cut and weld faster. This makes them great for car and airplane factories.

- CO2 lasers work better for things like plastics and glass. They help with jobs that do not need high precision.

- Fiber lasers cost more at first. But they need less fixing. They cost less to run over time. This makes them a good choice for the future.

- Knowing what material you have and what the job needs helps you pick the right laser. This makes your welding work better and faster.

Laser Welding: Key Differences

Comparison Table

It is important to know how fiber laser welding and CO2 laser welding are different. The table below helps you compare them in many ways:

| Parameter | Fiber Laser Welding | CO2 Laser Welding |

|---|---|---|

| Wavelength | 1.064 µm (low) | 10.6 µm (high) |

| Efficiency | High | Moderate |

| Material Compatibility | Best for metals | Best for non-metals |

| Maintenance | Compact design, less frequent repairs | Complex structure, more frequent repairs |

| Operating Costs | Lower | Higher |

| Application Focus | High-end manufacturing, automotive, aerospace, electronics, medical | Metal processing, automotive, aerospace, electronics |

| Power Consumption | Lower for same output | Higher for same output |

| Up-front Cost | Higher | Lower |

| Cut Precision | Higher | Lower |

| Working Life | Up to 25,000 hours | Shorter lifespan |

| Speed | Up to 300% faster for thick cuts | Slower for thick cuts |

Tip: If you want to weld faster and stop less for repairs, fiber laser welding works better, especially with metals.

Summary of Distinctions

You can see the biggest differences between fiber and CO2 laser welding by looking at what each one does best:

- Fiber lasers use a lower wavelength. This helps them work well with metals. CO2 lasers use a higher wavelength and are better for non-metals.

- Fiber laser welding is more efficient. It uses less power for the same job. This means you save energy and finish work faster.

- Fiber lasers do not need as much maintenance. They are smaller and last longer. You will spend less time and money fixing them.

- Fiber lasers cut and weld faster than CO2 lasers. For example, a fiber laser can cut 1mm stainless steel at 20-25 meters per minute. A CO2 laser can only cut it at 8-10 meters per minute.

- If you need high precision and speed, fiber laser welding is the best choice. It can work up to 300% faster on thick materials.

- CO2 lasers cost less at first. But you will pay more later because they need more repairs and use more energy.

- Fiber laser welding is good for high-end manufacturing, cars, airplanes, and medical jobs. CO2 lasers are still useful for some metal and non-metal work.

Note: Fiber laser welding is faster, more precise, and costs less to run. CO2 laser welding is still good if you work with non-metals or want to spend less at the start.

How Fiber and CO2 Lasers Work

Fiber Laser Welding Principles

When you use fiber laser welding, you rely on a focused beam of light to join metal parts. The laser energy melts the edges of the metal, creating a strong bond. You can control the process by adjusting three main settings: power, speed, and pulse width. Each setting changes how deep the weld goes, how wide the bead is, and how much heat you add.

Here is a table that shows how these parameters affect the welding process:

| Parameter | Typical Range | Effect on Welding | Potential Issue |

|---|---|---|---|

| Power (kW) | 0.5 – 3 | Changes penetration depth | Too much can cause blow-through |

| Speed (mm/s) | 5 – 60 | Alters bead width | Too slow may cause excess spatter |

| Pulse Width (ms) | 0.5 – 10 | Controls heat per pulse | Too short can create craters |

You will see a “keyhole” effect during welding. The laser vaporizes a small spot, pushing molten metal outward. This helps you make deep, narrow welds with little distortion. You can fine-tune the settings to get the best results for each job.

- You focus the laser energy right where you need it.

- The keyhole effect lets you weld thick or thin metals.

- Careful control of power, speed, and pulse width gives you clean, strong welds.

Tip: Fiber laser welding works best when you need precise, fast, and repeatable results.

CO2 Laser Welding Principles

CO2 laser welding uses a different setup. You start with a laser generator that creates the beam. The optical system, made of mirrors and lenses, guides the beam to the workpiece. The focusing system makes the beam very small and intense.

Here are the main parts of a CO2 laser welding system:

| Component | Description |

|---|---|

| Laser Generator | Makes the laser beam |

| Optical System | Moves and focuses the beam |

| Focusing and Focus System | Sets the size of the laser spot |

| Laser Scanning Galvo | Directs the beam path for accuracy |

| Welding Head | Focuses the beam and adds shielding gas |

| Control System | Manages the welding process |

| Water Cooling System | Keeps the system cool and prevents overheating |

You use the laser to heat the metal until it melts and forms a pool. As you move the beam, the molten pool cools and becomes a solid weld. Shielding gas flows over the weld area to stop oxidation and keep the weld clean.

- The laser generator makes a strong beam.

- The optical system sends the beam to the metal.

- The laser melts the metal and forms a pool.

- The pool cools and creates a solid weld.

- Shielding gas protects the weld from air.

CO2 laser welding gives you good results for many metals and non-metals. You can use it for large or small jobs, but you need to keep the system cool and clean for the best performance.

Performance and Efficiency

Energy Use and Speed

When you compare energy use, fiber laser welding stands out. You use much less electricity with fiber lasers than with CO2 lasers. This means you save money and help the environment. Here are some facts to help you see the difference:

- Fiber laser welding consumes much less energy than CO2 laser welding.

- A 10 kW fiber laser uses only about one-fifth the power of two CO2 lasers with the same output.

- You can save up to €53,000 each year because of this efficiency.

- CO2 lasers need more repairs, which increases their energy use.

- Smart software in fiber laser systems helps you use energy even better.

You also work faster with fiber lasers. The beam is strong and focused, so you can weld thick materials quickly. You spend less time waiting for the job to finish. CO2 lasers move slower, especially when you work with thick metals. If you want to finish projects quickly and keep costs low, fiber laser welding is the better choice.

Tip: If you want to save energy and finish jobs faster, choose fiber laser welding.

Beam Quality and Precision

Beam quality affects how neat and strong your welds look. Fiber lasers give you a stable and high-quality beam. This helps you make fine welds with less heat damage. CO2 lasers have less predictable beam quality, which can make your welds less precise.

Here is a table that shows the difference:

| Laser Type | Beam Quality | Impact on Weld Precision |

|---|---|---|

| Fiber Laser | Superior and stable beam quality | Finer welds and reduced heat-affected zones |

| CO2 Laser | Less predictable beam quality | May affect precision of the welds |

You get cleaner results with fiber lasers. The welds look smooth and strong. You also see less heat damage around the weld. CO2 lasers can make wider welds, but you may notice more rough edges and heat marks. If you need high precision and want your work to look professional, fiber laser welding gives you the best results.

Material Compatibility in Laser Welding

Metals and Reflective Materials

It is important to know which laser works best for metals. Fiber lasers are better for metals and shiny materials than CO2 lasers. The table below shows how each laser type works:

| Laser Type | Effective On | Less Effective On |

|---|---|---|

| Fiber | Metals, Reflective | Non-metals |

| CO2 | Non-metals | Metals |

If you use metals like steel, stainless steel, copper, or aluminum, fiber lasers make strong and clean welds. Fiber lasers have a shorter wavelength. Metals take in this energy well. This makes welding fast and easy.

CO2 lasers do not work well with shiny metals. You can have trouble welding copper or aluminum. These metals bounce most of the laser energy away. Here are some problems you might see:

- Copper bounces back over 95% of the laser light, so welds can be weak or not even.

- Aluminum bounces back more than 90% of the laser energy, so it is hard to start welding.

- The laser beam can bounce off the metal, which makes welding harder.

- Thick pieces of these metals are even tougher to weld with CO2 lasers.

If you want to weld metals, especially shiny ones, fiber lasers are the best choice.

Non-Metals and Organic Materials

CO2 lasers work great for non-metals and organic things. You can use them on wood, glass, leather, and plastics. The longer wavelength of a CO2 laser gets taken in by these materials. This helps you make smooth and neat cuts or welds.

Fiber lasers do not work well on non-metals. You may get bad results or even ruin the material. For jobs with plastics, glass, or wood, CO2 lasers are the best pick.

Tip: Use fiber lasers for metals and shiny materials. Use CO2 lasers for non-metals and organic things. This helps you get the best results for your laser welding projects.

Pros and Cons

Fiber Laser Welding Advantages and Drawbacks

You get many benefits when you choose fiber laser welding. The process works fast and gives you very precise welds. You spend less time on each job, which helps you finish projects quickly. The focused laser beam lets you make accurate welds with fewer mistakes. You also save money because fiber lasers use less electricity and need fewer repairs. Most fiber laser machines last a long time—often over 100,000 hours—so you do not have to replace them often.

Here is a table that shows the main advantages:

| Advantage | Description |

|---|---|

| High Speed | Welds materials quickly, reducing production times. |

| Precision | Makes accurate welds, lowering the risk of defects. |

| Low Maintenance | Needs little upkeep and lasts a long time. |

| Reduced Costs | Uses less energy and fewer consumables, saving you money. |

You also use fewer welding rods and less shielding gas, which lowers your costs even more.

However, fiber laser welding has some drawbacks. The machines cost a lot at first, which can be hard for small businesses. You need special training to use the equipment safely and correctly. Fiber lasers do not work well on very thick materials. The system is sensitive to dust and dirt, so you must keep it clean. The optics are delicate and need careful handling. You also need to use special safety gear to protect yourself from the laser.

CO2 Laser Welding Advantages and Drawbacks

CO2 laser welding gives you some unique benefits. You can use it on many non-metal materials, like plastics and glass. The process creates a small heat-affected zone, so you see less damage around the weld. You can weld small parts without causing them to bend or change shape. Many industries, such as car and airplane makers, use CO2 lasers for these reasons.

Some of the main advantages include:

- Good precision for small parts.

- Works well on non-metals and some metals.

- Reduces the risk of heat damage or flaws.

But CO2 laser welding also has some downsides. The machines use more electricity and need more repairs. You may notice slower welding speeds, especially on thick metals. The equipment does not last as long as fiber lasers. You must clean and align the mirrors often, or the laser beam will not work right. The system can also get damaged by dust or heat. These factors can raise your costs and slow down your work.

If you want a system that works well on non-metals and does not need high precision, CO2 laser welding can be a good choice.

Applications of Laser Welding

Fiber Laser Welding Uses

Fiber laser welding is used in many industries. It helps people work faster and more accurately. Here are some ways fiber laser welding is used:

- Car makers use fiber lasers a lot. They use them to put together car bodies and make batteries for electric cars. These lasers help make cars strong and light.

- Airplane companies use fiber lasers to join special metal parts. They can make shapes that are complex and parts that are light for planes.

- Electronics companies use fiber lasers for tiny welds. They can join small pieces without hurting them.

- Metal shops use fiber lasers to cut and weld. This gives clean edges and strong joins.

- Fiber lasers help save materials and make things faster. You can make more products in less time.

Fiber laser welding is fast and does not waste much. It is good for jobs that need to be strong and exact.

CO2 Laser Welding Uses

CO2 laser welding is also used in many industries. You can use it for metals and non-metals. The table below shows where CO2 laser welding is used most:

| Industry | Applications |

|---|---|

| Automotive | Body panels, chassis parts, exhaust systems |

| Aerospace | Aircraft components |

| Electronics | Electrical enclosures |

| Manufacturing | Joining different metal parts |

CO2 lasers can weld big parts and things like plastic or glass. Many factories use CO2 lasers for jobs that do not need to be super exact. You see them in car factories, airplane plants, and electronics shops.

If you need to weld non-metals or big metal parts, CO2 laser welding works well.

Cost, Maintenance, and Environment

Investment and Operating Costs

When you compare prices, fiber laser welders cost more at first. You pay a higher price for the machine. But you save money later because it uses less energy. It also needs fewer repairs. CO2 laser welders are cheaper to buy. But you spend more each year to keep them working. The yearly costs are higher because they use more power and need more fixing.

Here is a table to help you see the difference:

| Type of Laser Welder | Typical Price Range (USD) | Ongoing Operating Costs (Annual) |

|---|---|---|

| Handheld Fiber Laser Welder | $3,000 – $50,000 | $3,000 – $6,000 |

| CO2 Laser Welder | Lower initial price | Higher due to lower efficiency |

If you want to spend less over time, fiber laser welding is better for saving money.

Maintenance Needs

Fiber laser welders do not need much fixing. Their design makes them strong and dependable. You do not have to change parts often. CO2 laser welders use gas and mirrors. You must clean and adjust them a lot. This means more time spent fixing and more money spent.

| Laser Type | Maintenance Requirements | Operational Costs |

|---|---|---|

| Fiber Laser | Lower due to solid-state construction and fiber optics | Lower due to energy efficiency |

| CO2 Laser | Higher due to reliance on gas mixes and mirrors | Higher due to less efficiency |

You fix fiber lasers less, so you can keep working without many stops.

Environmental Impact

Fiber laser welding is good for the environment. It uses less energy, so fewer greenhouse gases go into the air. Laser welding does not make much smoke or fumes. This keeps the air cleaner. You do not need extra rods or electrodes, so you make less waste. Many fiber laser systems use closed-loop cooling. This saves water and stops heat from hurting the environment.

- Fiber lasers use less power and can cut greenhouse gases by up to 45%.

- Laser welding makes almost no fumes, so the air stays clean.

- You do not waste materials because you do not need extra rods.

- Closed-loop cooling systems help save water and protect nature.

Picking fiber laser welding helps the planet and saves you money and time.

Choosing the Right Laser Welding Technology

Key Factors for Selection

You should think about a few things before picking a laser welding system. The kind of material you use is very important. Fiber lasers work best for metals like steel and aluminum. CO2 lasers are better for things like plastic, wood, and glass. You also need to check how thick your material is. Fiber lasers weld thin and medium-thick metals well. CO2 lasers do better with thick non-metal materials.

How much you need to make can change your choice. If you have a busy shop or factory, fiber lasers help you finish more work faster. They are quick and work well. CO2 lasers are good for smaller jobs or if you use many kinds of materials.

Here is a table that shows how these things compare:

| Criteria | Fiber Laser | CO2 Laser |

|---|---|---|

| Material Type | Best for metals (steel, aluminum) | Better for non-metallic materials |

| Thickness | Effective for thin to medium-thick | Suitable for thicker non-metal materials |

| Production Volume | High efficiency for industrial use | Versatile for various applications |

| Beam Quality | Superior precision and control | Less precision compared to fiber lasers |

| Wavelength | 1064 nm (high absorption for metals) | 10,600 nm (better for non-metals) |

Tip: Pick your laser based on the material and job size. This helps you get good results and saves time.

Practical Decision Guide

You can use a simple checklist to help you choose the right laser welding system:

- Pick fiber laser welding if you want fast and accurate welds for metals.

- Choose CO2 laser welding for non-metals or if you need to cut and engrave many materials.

- Think about how much you need to make. Fiber lasers are better for big batches and quick jobs.

- Check the thickness of your materials. Fiber lasers work on thin metals. CO2 lasers are better for thick non-metals.

- Look at your budget for fixing and energy. Fiber lasers save money over time.

Fiber lasers give you faster welding and more accuracy. This matters for jobs that need small details. CO2 lasers are good for cutting and engraving lots of non-metal materials.

Note: You make the best choice when you match your laser to your materials, how much you need to make, and your budget. This helps your welding projects go well and finish quickly.

You can notice the biggest ways fiber laser welding and CO2 laser welding are not the same. Fiber lasers make a better beam, cost less to use, and are great for metals. CO2 lasers can work with more types of non-metals. Look at this table to help you decide:

| Fiber Laser | CO2 Laser |

|---|---|

| Good for precision, fast jobs, and metals | Good for many uses and non-metals |

Think about what material you have, how fast you need to work, and how much money you want to spend. This will help you choose the right laser for your work.

FAQ

What materials can you weld with a fiber laser?

You can weld metals like steel, stainless steel, aluminum, and copper with a fiber laser. Fiber lasers work best on shiny and reflective metals. They do not work well on plastics or glass.

Is fiber laser welding safer than CO2 laser welding?

Both types need safety steps. Fiber lasers have a smaller, more focused beam, which can be safer if you use proper shields and goggles. Always follow safety rules to protect your eyes and skin.

How long does a fiber laser welder last?

A fiber laser welder can last up to 100,000 hours. You get a long working life with less need for repairs. This makes fiber lasers a good choice for busy shops.

Can you use CO2 lasers for thick metal welding?

You can weld some metals with a CO2 laser, but it works slower on thick metals. Fiber lasers weld thick metals faster and with better quality.

Which laser type costs less to run?

Fiber lasers cost less to run. You use less electricity and spend less on repairs. Over time, you save more money with a fiber laser.

See also

The working principle and basic process of laser welding

What Should Beginners Understand About Laser Welding

How to Remove Rust from Metal: 11 Different Methods

How to determine if a laser cleaning machine is worth buying