You will see that fiber laser cleaning machines work very well for cleaning in factories. They give a strong, steady beam and use energy well. They are easy to use and do not break down often. You save money and do not need to fix them much. Many businesses, like car and airplane companies, use fiber lasers to clean things.

- In 2023, fiber lasers made up about 69% of all money earned in the laser cleaning market.

- Solid-state lasers, like fiber lasers, are strong and very exact.

- Solid lasers do not need much fixing and give a lot of power.

You will see simple, real-life examples that show these facts.

Key Takeaways

- Fiber laser cleaning machines work well and use less energy. They use 30-50% of power for laser energy. Older CO₂ lasers only use 10-15% for laser energy.

- These machines are very precise. They can clean delicate parts safely. They do not harm the surface underneath.

- Fiber lasers clean fast. They can clean up to 20 square meters in one hour. This is for light rust. You can finish jobs faster.

- One fiber laser cleaning machine can do many jobs. You do not need many different tools. This helps you save money.

- Fiber laser machines do not need much care. They last 50,000 to 100,000 hours before repairs.

- Using fiber lasers is good for the environment. They make less waste. They do not need strong chemicals for cleaning.

- Buying fiber laser cleaning machines can save a lot of money. They often pay for themselves in 12 to 24 months.

- Many industries use fiber lasers, like automotive and aerospace. They say cleaning is faster and product quality is better.

Performance

Fiber Laser Cleaning Machine: Beam Quality

Precision Cleaning

You want a cleaning tool that gives you good control. A fiber laser cleaning machine lets you clean small spots. It does not hurt the surface under the dirt. The beam stays sharp and focused. You can remove rust, paint, or dirt from tiny places. This helps you clean delicate parts in cars or airplanes. You do not cause damage. Solid-state lasers also give good control. But fiber lasers are even more accurate because their beam is stable and narrow.

Consistency on Surfaces

When you use a fiber laser cleaning machine, you get the same results each time. The beam does not lose power or shape as you move it. You can clean big areas or small parts with the same quality. You do not worry about missed spots or uneven cleaning. Many industries pick fiber lasers because they work well on rough or layered materials.

Efficiency & Speed

Removal Rate

You want to finish cleaning jobs fast and save time. Fiber laser cleaning machines work quickly. They are great for removing rust, paint, or coatings. The table below shows how fast you can clean different things with a fiber laser:

| Application | Cleaning Speed (sq. meters/hour) |

|---|---|

| Light Rust | Up to 20 |

| Heavy Rust | 5-10 |

| Single Layer Paint | 10-15 |

| Multi-Layer Coatings | 3-7 |

| Welding Preparation | 10-12 |

| Aerospace Components | Varies (slower for precision) |

| Adhesion Improvement | 15-25 |

You can see fiber laser cleaning machines clean up to 20 square meters per hour for light rust. They clean even faster when improving adhesion. This speed helps you finish projects faster than most solid-state lasers.

Application Versatility

A fiber laser cleaning machine works on many materials. You can use it for metal cleaning, rust removal, and paint stripping. It helps with welding preparation and cleaning aerospace parts. You find these machines in car factories and airplane workshops. They are also used in medicine and construction. One machine can do many jobs. You do not need to buy lots of tools.

Tip: Fiber laser cleaning machines can clean narrow or hard-to-reach spaces. They use a contactless method. This makes them good for detailed or complex parts.

You also get new technology. Modern fiber lasers use MOPA designs. This lets you change the pulse and power. You can clean without hurting the base material. You get better results and protect your equipment.

In summary:

- You get high precision and steady cleaning with a fiber laser cleaning machine.

- You finish jobs faster and can clean many types of surfaces.

- You can use one machine for many tasks, saving you money and space.

Operational Advantages

Energy Efficiency

Power Conversion

You want a machine that does not waste electricity. Fiber laser cleaning machines use more of the power they get. They turn more wall power into laser energy. Most fiber lasers use 30% to 50% of the power for the laser beam. Older CO₂ lasers only use about 10% to 15%. This means you need less electricity for the same cleaning job.

- Fiber lasers change 30–50% of power into laser energy.

- CO₂ lasers only change about 10–15%.

- A 6 kW fiber laser cutter uses about 22 kW of power, but a 6 kW CO₂ machine uses 65 kW.

You save energy each time you use a fiber laser cleaning machine. This helps the planet and lowers your electric bills.

Cost Savings

Using less power means you spend less money. Over time, these savings grow bigger. You will see a big drop in your energy bills if you switch from a CO₂ or other solid-state laser to a fiber laser cleaning machine. High efficiency lets you use your machine longer without high costs. Many factories pick fiber lasers to save money and keep profits up.

💡 Tip: Using less energy saves money and helps your business be greener.

Maintenance & Durability

Component Lifespan

You want your machine to last many years. Fiber laser cleaning machines are known for being tough. Most fiber lasers work for 50,000 to 100,000 hours before needing new parts. This long life means you do not worry about repairs often. Diode lasers also last long, but fiber lasers usually last even longer.

Downtime Reduction

Less fixing means more time working. Fiber laser cleaning machines need little care. You do not have to change parts often. Most problems come from too much heat, dirty lenses, or power issues. You can stop these problems by keeping the machine clean and checking the cooling.

| Maintenance Challenge | Causes |

|---|---|

| Overheating | Not enough coolant, blocked filters, blocked vents, high heat |

| Poor Cleaning Quality | Dirty or broken lenses, not lined up, wrong settings, laser source wear |

| Laser Source Instability | Power changes, inside damage, harsh places |

You can fix most problems fast. Checking and cleaning often keeps your fiber laser cleaning machine working well. This means you spend less time fixing and more time working.

Note: Fiber laser cleaning machines are small and easy to fit in your shop. Their simple build makes them easy to move and set up, which helps them work better.

User Experience

Ease of Use

Setup Simplicity

You want a cleaning machine that is easy to set up. Fiber laser cleaning machines are simple to install. You do not need many tools or special training. Most machines come with clear directions. You plug in the machine and check the wires. Then you can start cleaning right away. The control panel has easy buttons and screens. You can change the settings without getting confused. Solid-state lasers sometimes take more steps to set up. Fiber lasers help you save time and work less during setup.

Flexibility in Application

You can use fiber laser cleaning machines for many tasks. You clean metal, take off paint, and get surfaces ready for welding. The machine works on flat, round, or detailed parts. You can switch jobs by changing the settings. You do not need to buy new tools for each job. This makes it easy to do more work with one machine. You can move the machine around your shop or factory. The small size lets it fit in tight spaces.

Tip: You can clean small or tricky spots with fiber lasers. The contactless way keeps parts safe from scratches.

Safety & Environment

Operator Safety

You must stay safe when using laser cleaning machines. Fiber lasers and solid-state lasers both need careful use. You learn how to use lasers before you start. You study laser basics and how the machine works. You get to know each part of the cleaning system. Training teaches you about laser dangers and how to stay safe. You follow strict safety rules to protect yourself and others.

- You learn how lasers work.

- You study laser basics for safety.

- You get to know the machine’s parts.

- You learn about laser dangers.

- You follow safety rules.

Factories keep records to show you finished training. They use safety steps and checklists. You wear safety gear like goggles and gloves. Regular checks and care keep the machines safe to use.

| Evidence Type | Description |

|---|---|

| Procedures | Standard steps for using, fixing, and handling emergencies. |

| Training Records | Proof that you finished training and know what to do. |

| PPE Records | Logs that show you use and check safety gear. |

| Maintenance and Audit Logs | Notes about fixing and checking the safety systems. |

| Incident Reports | Papers about accidents and what happened. |

| Version Control | Clear tracking for safety steps and risk checks. |

| Retention Policy | Rules for keeping training and accident records. |

| Audit-Ready Dashboard | Monthly checks of safety numbers and problems. |

Environmental Impact

You help the planet when you use fiber laser cleaning machines. These machines use less power than old ones. You do not need chemicals or strong cleaners. The process makes very little waste. You keep your work area cleaner and safer. Fiber lasers make less noise and fewer fumes. You help keep the air and water clean near your factory. Many companies pick fiber lasers to be greener and cut down on pollution.

💡 Note: Using fiber laser cleaning machines helps you save energy and protect the planet. You make your workplace safer and the world cleaner.

Cost-Benefit

Investment vs. Value

Initial Cost

If you look at fiber laser cleaning machines, you might see the price is higher than some solid-state lasers. A mid-range fiber laser cleaning machine costs about $30,000 to $60,000. This price includes advanced technology, a strong build, and easy controls. You pay more at first, but the machine lasts longer and needs less fixing. You also save money because you do not need chemicals or extra cleaning tools. Many companies think this is a smart choice.

Long-Term ROI

You want your money to work for you fast. Fiber laser cleaning machines often do this. Many U.S. companies say these machines pay for themselves in 12 to 24 months. Some people see a return in just 6 to 18 months, especially with mid-range models. You save money with lower energy bills, less downtime, and fewer repairs. If you clean a lot or do special jobs, you can earn even more. The machine helps you finish jobs faster, so you can do more work and make more money.

- Many machines pay for themselves in 12–24 months.

- ROI can happen in 6–18 months with mid-range machines.

- Big cleaning jobs and special projects help you earn more.

Real-World Results

Case Studies

You can see how fiber laser cleaning machines help real businesses. In aerospace, companies use these machines to clean turbine blades. They save 25% on maintenance and finish jobs faster. Cleaner blades help engines work better and last longer. In cars, fiber lasers remove rust before welding. This cuts cleaning time by 40% and makes welds stronger. The marine industry uses fiber lasers to clean ship hulls. This helps ships use 15% less fuel and work with less downtime.

- Aerospace: 25% savings and better engines.

- Automotive: 40% faster cleaning and stronger welds.

- Marine: 15% better fuel use and less downtime.

Industry Feedback

Many people say good things about fiber laser cleaning machines. Workers think they are easy to use and safe. Managers like the lower costs and fast payback. Companies see fewer mistakes and better products. You can trust fiber laser cleaning machines to help you save money, work faster, and get better results. Many businesses now pick fiber lasers because they see clear benefits every day.

💡 Tip: When you buy a fiber laser cleaning machine, you get more than a tool. You get a helpful partner that helps your business grow and stay ahead.

Fiber Laser Cleaning Machine vs. Solid-State: Summary

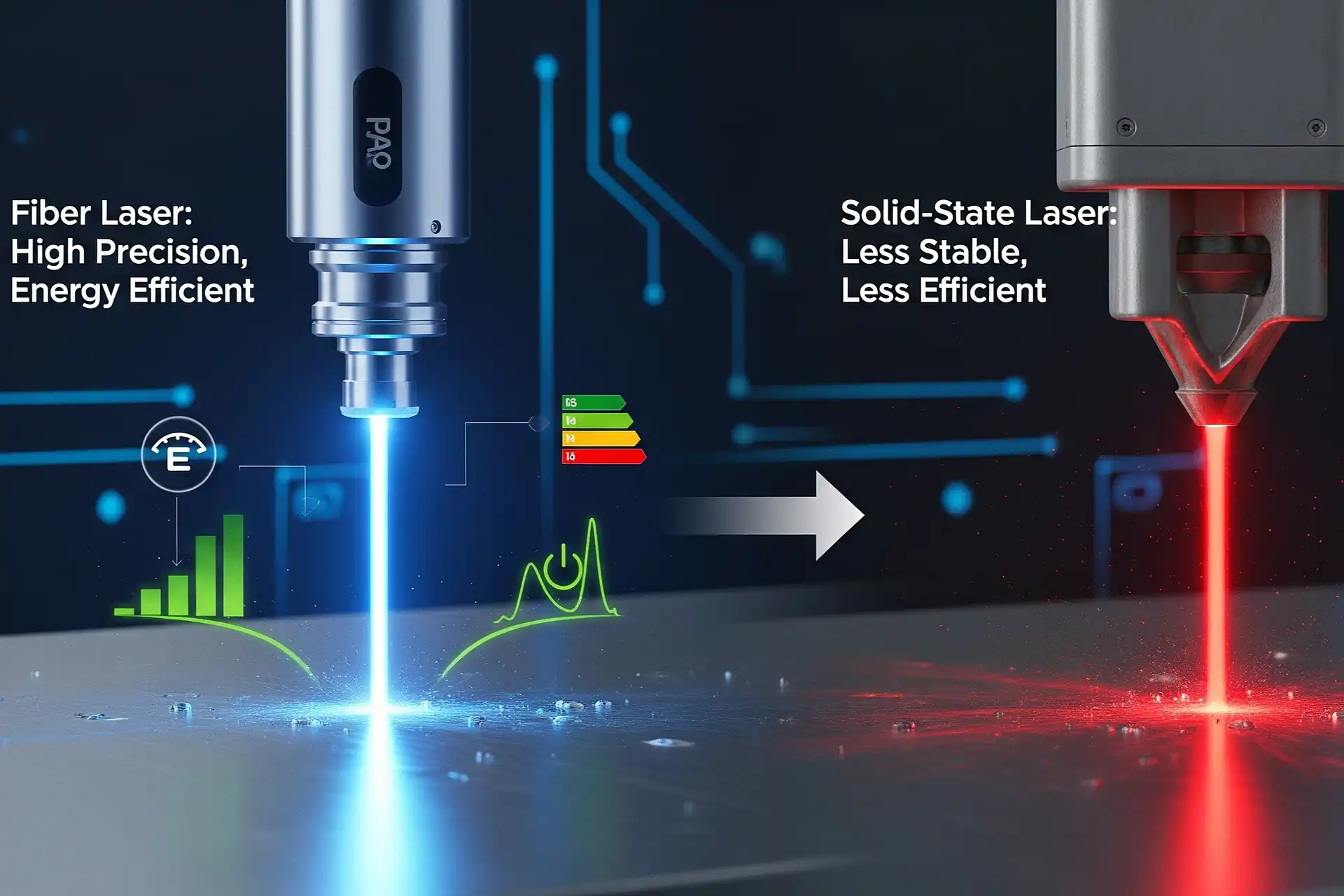

You want the best cleaning machine for your job. Both fiber laser cleaning machines and solid-state lasers work well. But fiber laser cleaning machines give you more real-life benefits.

Fiber lasers have high beam quality. The beam is sharp and focused. This lets you clean small spots and delicate parts safely. You finish jobs faster because fiber lasers are quick. They use less energy, so you save money each month.

Fiber laser cleaning machines last a long time. You do not fix them often. You spend less time on repairs and more time working. These machines are easy to set up and move. You can use them for many jobs, like rust removal and paint stripping.

Fiber lasers also help the planet. They use less power and do not need chemicals. Your workspace stays safe and clean. You protect your workers and the environment.

Here is a simple table that compares fiber laser cleaning machines and solid-state lasers for rust removal:

| Metric | Fiber Laser Solutions for Rust Removal |

|---|---|

| Laser Power | Various levels available |

| Speed | High efficiency |

| Efficiency | Superior in rust removal |

| Weight | Lightweight options |

| Cost | Competitive pricing |

Fiber laser cleaning machines are efficient and have many power choices. You can pick a lightweight model that fits your needs. The price is fair, and you get strong cleaning results.

Tip: If you want a fast, energy-saving, and long-lasting machine, a fiber laser cleaning machine is a smart pick.

Many industries give good feedback about fiber lasers. Car makers, airplane companies, and shipyards use them. They finish jobs faster and save money. You can trust fiber laser cleaning machines to give steady results every day.

When you compare both types, fiber laser cleaning machines stand out. You get better cleaning, lower costs, and a safer workplace. You make a smart choice for your business and the planet.

Fiber laser cleaning machines are great for cleaning in factories. They use less energy and work on many surfaces. You can clean without touching the parts. This keeps delicate pieces safe.

- Fiber lasers can clean hard or soft jobs.

- You do not need chemicals, so there is less waste.

- You spend less money because you fix them less.

Remember, picking fiber laser cleaning helps your business stay clean, safe, and dependable in the future.

FAQ

What materials can you clean with a fiber laser cleaning machine?

You can clean metals like steel, aluminum, copper, and titanium. Fiber lasers also remove paint, rust, and coatings from many surfaces. They work well on flat and curved parts.

Is fiber laser cleaning safe for operators?

Fiber laser cleaning is safe if you follow safety rules. You must wear goggles and gloves to protect yourself. Training is needed before you use the machine. Always check safety features before you start.

How much maintenance does a fiber laser cleaning machine need?

You should clean the lens and check the cooling system often. Most machines do not need much care. Following the care guide helps your machine last longer.

Can you use fiber laser cleaning machines outdoors?

You can use these machines outside. Keep the machine safe from rain and dust. Make sure the power supply is steady. Always follow safety steps when working outdoors.

How long does it take to learn to use a fiber laser cleaning machine?

Most people learn the basics in a few hours. It takes a few days to learn advanced settings. Clear instructions and simple controls make learning easy.

Does fiber laser cleaning damage the base material?

Fiber laser cleaning does not hurt the base material if you use the right settings. You can change the power and speed for each job. This keeps surfaces safe and clean.

See also

How Quickly Can a Laser Cleaning Machine Work

Is Renting or Buying a Laser Cleaning Machine More Cost-Effective

Introduction to Main Components and Functions of Laser Cleaners