You can use a Laser Cleaning Machine to clean surfaces fast. Some machines can take off rust at about 3 square feet each minute with a 2000W pulsed laser. The best setups can clean 15 to 25 square meters every hour. How fast you clean is important because it changes how quickly you finish work. In car factories, cleaning fast means parts are ready for the next step right away. Easy setup, smart controls, and cleaning modes you can use again help you save time and work better.

Key Takeaways

- Laser cleaning machines can clean 25 square meters each hour. This makes them good for big jobs.

- Pick a machine with more power to clean faster. A 2000W laser can clean rust at 3 square feet each minute.

- Cleaning speed changes with different materials. Metals clean the fastest. Glass should not be cleaned with a laser.

- Setting up and taking care of the machine helps it clean faster and safer. Always use the machine the right way.

- Laser cleaning saves time and does not use strong chemicals. This makes it safer and cleaner for getting surfaces ready.

Laser Cleaning Machine Speed Metrics

Typical Cleaning Rates

You can check how fast a Laser Cleaning Machine works by looking at cleaning rates. Cleaning rates show how much area gets cleaned in a certain time. Most machines clean metal surfaces fast. Some machines clean rust at 3 square feet each minute with a 2000W pulsed laser. Advanced machines can clean up to 25 square meters every hour for big jobs.

Tip: To clean faster, pick a machine with more power. Set it up for your job.

The cleaning rate changes with the material. Here is a table that shows how a Laser Cleaning Machine works on different surfaces:

| Material | Cleaning Rate | Effectiveness Description |

|---|---|---|

| Metals | High | Takes off rust, paint, and dirt well. No damage. |

| Stone | Moderate | Works okay. Depends on what the stone is like. |

| Glass | Low | Not good. Glass can break or get hurt. |

Metals clean the fastest. Stone takes longer because it has rough spots. Glass is not good for laser cleaning. It can crack or get ruined.

Cleaning Times for Common Surfaces

You might want to know how long it takes to clean things with a Laser Cleaning Machine. Here are some examples:

- Rust on steel: You clean 3 square feet in one minute. A big steel beam takes less than an hour.

- Paint on aluminum: You clean paint as fast as rust. A car door takes just a few minutes.

- Stone walls: Stone takes more time. You clean half as much as metal in the same time.

- Adhesion preparation: You can get surfaces ready for glue or coating at up to 25 square meters per hour with the best machines.

Note: Cleaning time depends on how thick the dirt is and what kind of Laser Cleaning Machine you use.

If you plan your cleaning job, you save time and do better work. Pick the right machine and set the speed for your surface. This helps you finish faster and keeps the surface safe.

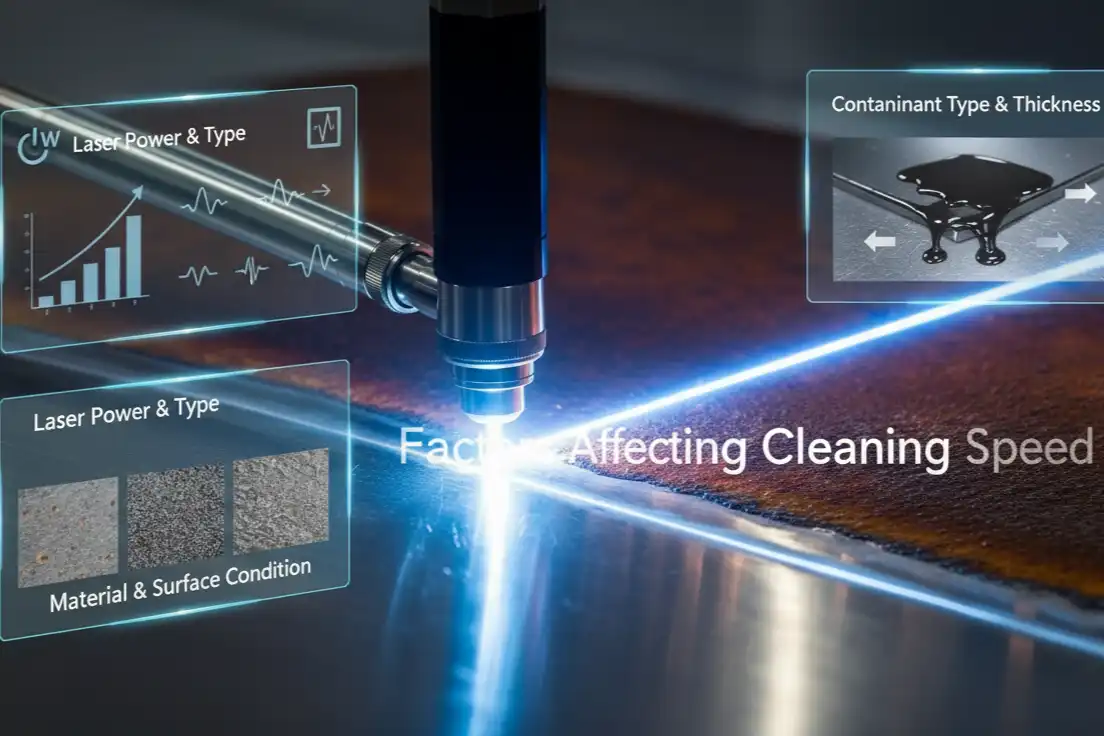

Factors Affecting Cleaning Speed

Material and Surface Condition

The kind of material matters for cleaning speed. Metals clean fast. Glass does not clean well with lasers. Here are some things to know: Harder materials take longer to clean. If a material is shiny, like aluminum, the laser bounces off and slows cleaning. Rough surfaces help the laser work better because they hold more energy. If there is thick rust or paint, you need more power and time. Thin rust or paint comes off faster. When you take off the top layer, the surface soaks up more energy. This makes cleaning go quicker.

Contaminant Type and Thickness

The type of dirt or coating changes how fast you clean. Some dirt comes off easy. Other dirt takes more time. Look at this table for examples:

| Contaminant Type | Thickness Challenge | Removal Rate |

|---|---|---|

| Heavy Lubricant Buildup | Up to 2 m²/hour | 0.1 mm in 8 seconds |

| Rust (FeO, Fe2O3) | 0.1 mm thickness | 8 seconds per m² |

| Rubber Residues | 90% absorption | Vaporizes at 3,500°C |

Oil and other organic dirt come off best with CO2 lasers. Rust and other inorganic dirt need different laser settings. Thick layers always take longer to clean.

Laser Power and Type

The laser’s power and type change how fast you clean. A 2000W laser is two or three times faster than a 1000W laser. Here is a quick chart:

| Laser Power | Cleaning Speed | Application Areas |

|---|---|---|

| 1000W | Moderate | Electronics, molds, small parts |

| 2000W | Fast | Shipbuilding, rail, steel industry |

Continuous wave lasers clean big areas or thick stains faster. Pulsed lasers are better for small spots or thin layers.

| Laser Type | Cleaning Speed | Best For |

|---|---|---|

| Continuous Wave | Fast | Large areas, thick stains |

| Pulsed | Slower | Small areas, thin stains |

Operator and Environment

Your skills and the place you work matter too. The best temperature is between 15℃ and 30℃. The best humidity is between 30% and 65%. Too much water in the air makes water on surfaces. Too little makes static electricity. Both slow down cleaning.

| Factor | Impact on Cleaning Speed |

|---|---|

| Ambient Temperature | Wrong temperature can slow the machine |

| Relative Humidity | Too high or low causes water or static electricity |

| Repeatability | Changing conditions make cleaning slower and less steady |

You clean faster if you use good habits. Wear safety gear. Set up the machine for your job. Keep the software up to date. Take care of your Laser Cleaning Machine so it works its best.

Tip: Good setup and safe habits help you clean faster and safer every time.

Real-World Applications

Rust Removal

You can use a Laser Cleaning Machine to remove rust from steel quickly. The speed depends on the laser power and the thickness of the rust. For example, a 2.0 kW laser can clean light paint or rust at 5–9 square meters per hour. If you deal with heavy layers, the speed drops to 2–4 square meters per hour. Higher power lasers clean even faster. You can see the cleaning rates in the table below:

| Laser Power (kW) | Light Paint (m²/h) | Heavy Layers (m²/h) |

|---|---|---|

| 1.5 | 3–6 | 1–2 |

| 2.0 | 5–9 | 2–4 |

| 3.0 | 8–14 | 4–6 |

| 6.0 | 15–25 | 7–12 |

Laser cleaning works faster than sandblasting or chemical cleaning. You do not need extra steps after cleaning, so you save time and effort.

Paint Stripping

You can strip paint from metal or other surfaces with high speed. The type of paint affects how fast you finish. Some paints need more energy to remove. If the laser energy is too low, the paint stays. If it is too high, you might damage the surface. You should match the laser settings to the paint type for the best results. Most users clean car doors or machine parts in just a few minutes.

Adhesion Preparation

When you need to prepare a surface for glue or coating, laser cleaning gives you a fast and even result. You can clean up to 15–25 square meters per hour with high-power lasers. The process removes dirt and old layers in seconds. This makes the surface ready for bonding or painting. You get a clean, rough surface that helps glue or paint stick better. Laser cleaning also makes your work repeatable and easy to scale up for big jobs.

Tip: Use laser cleaning for fast, precise, and repeatable surface prep. You will improve your production speed and quality.

Laser Cleaning Machine vs. Other Methods

Speed Comparison

You might wonder how a Laser Cleaning Machine stacks up against sandblasting or chemical cleaning. Each method has its own speed and strengths. Sandblasting can clean large areas quickly. You see fast results on big metal surfaces. However, you need to handle the equipment and clean up the mess afterward. Laser cleaning works slower per square meter, but you get more control and accuracy. You can target small spots without damaging the rest of the surface. Chemical cleaning sometimes removes paint or rust fast, but you must wait for chemicals to work and then rinse everything off.

- Sandblasting cleans large areas fast but needs more manual work and cleanup.

- Laser cleaning gives you precision and less downtime.

- Chemical cleaning can be quick but often requires extra steps.

Note: The best method depends on your job. If you need speed for a big area, sandblasting might win. If you want detail and safety, laser cleaning is a better choice.

Practical Considerations

When you choose a cleaning method, think about more than just speed. Laser cleaning technology helps you cut down on maintenance downtime. You do not need to stop work for long periods. You also avoid harsh chemicals, which makes your workspace safer. High-power lasers remove dirt and rust without long manual steps. This means you finish maintenance faster and get back to work sooner.

- Laser cleaning reduces downtime because you do not need to set up or clean up as much.

- You avoid using chemicals, so you keep your team safer.

- You can fit laser cleaning into your regular maintenance schedule and boost productivity.

Tip: If you want to save time and keep your work area clean, consider using a Laser Cleaning Machine for your next project.

You can clean things quickly and accurately with a Laser Cleaning Machine. Some machines can clean up to 25 square meters in one hour. How fast you clean depends on a few things. These things are laser power, how the laser scans, what the material is, and how easy the machine moves.

Pick a machine that fits your job. Continuous lasers are good for tough jobs. Pulsed lasers are better for gentle surfaces.

| Key Factor | Why It Matters |

|---|---|

| Power Output | More power means faster cleaning |

| Scanning Strategy | Smart patterns help save time |

| Material Compatibility | Makes sure cleaning is safe and works well |

Think about what you need to clean and how you work. This helps you get the fastest cleaning speed.

FAQ

How fast can you clean with a laser cleaning machine?

You can clean up to 25 square meters per hour with high-power machines. Most jobs finish much faster than with traditional methods.

Does laser cleaning damage the surface?

You control the laser settings. When you use the right settings, you protect the surface. Laser cleaning removes only the unwanted layer.

What surfaces work best with laser cleaning?

Metals clean the fastest.

Stone works well but takes longer.

Glass is not recommended because it can crack.

Is laser cleaning safe for operators?

You stay safe by wearing protective gear and following safety rules. Modern machines have safety features to help you work safely.

Can you use laser cleaning outdoors?

Yes, you can use laser cleaning outdoors. Make sure the weather is dry and the area is clear. Wet or windy conditions can slow down the process.

See also

Is Renting or Buying a Laser Cleaning Machine More Cost-Effective

Introduction to Main Components and Functions of Laser Cleaners

The Working Principle of Laser Cleaning for Beginners

Common problems and solutions in the use of laser cleaning machines