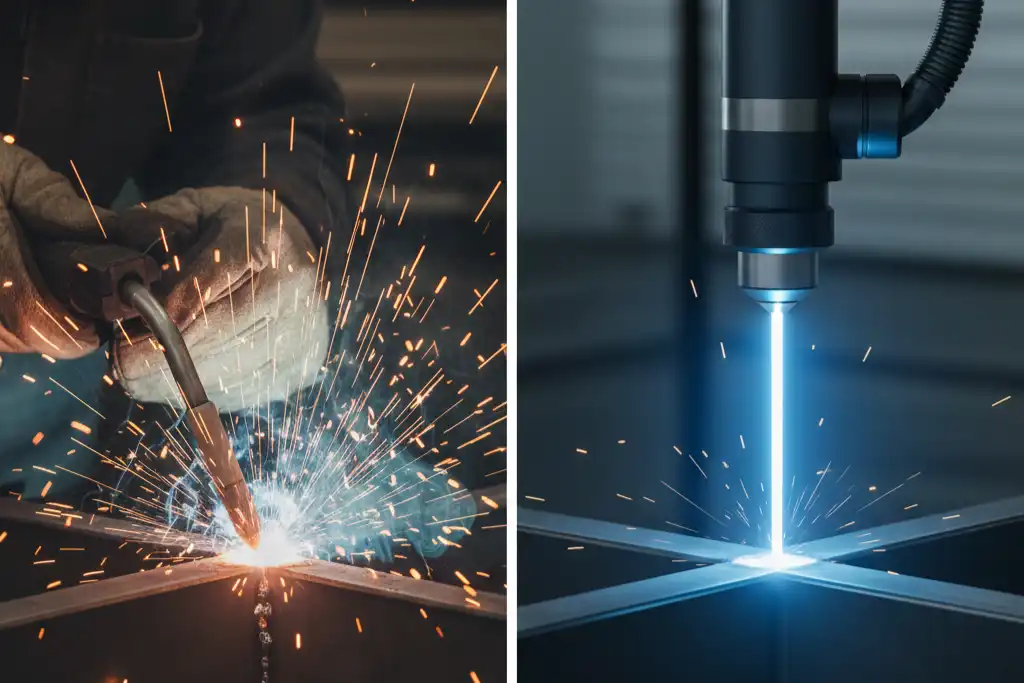

You may ask which welding method is best for your project. Laser welding is quick, very accurate, and causes less bending. Traditional welding is good for thick materials and is more flexible. You should think about your material, how thick it is, your budget, and the look you want. Use the side-by-side chart to help you pick the best method.

Key Takeaways

- Laser welding works quickly and is very exact. It is best for thin materials. It is good for projects that need high accuracy.

- Traditional welding methods like MIG, TIG, and Stick work better for thick materials. They are good for outdoor jobs. These methods are flexible and make strong joints.

- Think about your project’s material type. Also, think about your budget. Decide how you want the weld to look before you choose laser or traditional welding.

- Laser welding causes less heat damage. It also takes less time to clean up. This makes welds look better and last longer.

- Laser welding costs more at first. But it can save money later. It is efficient and makes less waste.

What Is Laser Welding?

How Laser Welding Works

Laser welding joins two pieces of metal or other materials. It uses a strong light beam on a small spot. The light makes enough heat to melt and join the materials. You can control the laser to heat only the spot you want. This gives you a neat and exact weld.

Tip: Laser welding makes a small melted area at the joint. There is less bending because the heat stays in one place.

Here are some ways laser welding is different from traditional welding:

- The laser beam is focused, so you get very exact welds.

- You can use it on many kinds of materials.

- It lets you finish work faster, which is good for making lots of things.

- The finished product does not bend or change shape as much.

Laser Welding Applications

Laser welding is used in many jobs. Companies pick it when they need strong, neat welds and quick work. Some main areas are:

- Automotive

- Aerospace

- Jewelry

- Electronics

- Medical devices

- Energy

Laser welding is good for these jobs because it gives exact results. It also keeps parts from getting too hot or bent. This method is used a lot when machines do the work. For example, car companies use laser welding to join body panels fast and with few mistakes. Medical device makers use it to make small, clean welds for tools and implants.

Note: Laser welding helps you get very exact and fast work. There is less heat damage, so your finished product looks better and lasts longer.

If you want a fast, neat, and exact weld, laser welding could be the best choice for your project.

Traditional Welding Methods

Overview of MIG, TIG, and Stick

There are three main types of traditional welding. These are MIG, TIG, and Stick. Each one works in its own way. Each is good for different jobs.

| Welding Method | Process Description | Applications | Advantages | Disadvantages |

|---|---|---|---|---|

| Stick Welding | Uses a fixed-length electrode to make an arc and melt metal. | Works well for iron and steel, and in any position. | Costs less, easy to change, fits small spaces. | Slower, makes more mess, needs cleaning after. |

| MIG Welding | Pushes a wire through a gun with shielding gas. | Good for thick and thin materials. | Fast, strong welds, not much cleaning needed. | Hard to use outside, needs clean metal. |

| TIG Welding | Uses a tungsten tip and adds filler by hand. | Best for aluminum and careful work. | Makes the cleanest and best-looking welds. | Hard to learn, slow, needs very clean metal. |

- Stick Welding is good for iron and steel. You can use it in many places, even outside. It does not cost much. It fits in small spaces. You need to clean up after you finish.

- MIG Welding uses wire and gas to make strong welds. You can finish jobs fast. You do not need to clean much. You need clean metal. It does not work well outside.

- TIG Welding makes the neatest welds. You use a tungsten tip and add filler by hand. It is best for aluminum and jobs that need to look perfect. It takes more skill and time.

Tip: MIG is good if you want a fast and easy weld. TIG is best for strong and neat welds. Stick welding works well for outdoor jobs and thick metal.

Common Uses

These welding methods are used in many places. Each one is good for special jobs.

| Welding Method | Industries Using It |

|---|---|

| MIG Welding | Manufacturing, Automotive, Home Appliances, Metal Furniture |

| TIG Welding | Aerospace, Automotive, Medical |

| Stick Welding | Construction, Maintenance, Heavy Equipment Repair |

MIG welding is used in car factories and for metal furniture. TIG welding helps make airplanes and medical tools. Stick welding is used for building and fixing big machines.

Note: You can choose the best welding method by looking at your project’s material, where you work, and how you want it to look. Each method has its own strengths for your job.

Precision and Quality

Laser Welding Precision

You want your welds to look neat and strong. Laser welding is very exact. The laser heats only a tiny spot. This makes the seam small and smooth. You can control the laser for tiny joints. Factories use laser welding for faster and better work.

- Laser welding makes jobs quicker and more exact.

- Production can be 40% faster with laser welding.

- A strong laser heats a small spot for smooth seams.

- Laser welding makes seams in millimeters, not centimeters.

- The process is up to four times faster, so you finish quickly.

Tip: If you want a clean look and perfect fit, pick laser welding. You get less heat damage and better results.

Traditional Weld Quality

Traditional welding like MIG, TIG, and Stick has been trusted for years. These welds are used for big jobs like buildings and bridges. Welders follow strict rules for safe and strong joints.

| Standard | Description |

|---|---|

| AWS D1.1 | Covers steel welding for buildings and bridges. |

| ISO 3834 | Makes sure welding is reliable for aerospace and energy. |

| ASME Section IX | Sets rules for welding and brazing for boilers and pipelines. |

You see these rules where safety is very important. Welders check their work to meet these standards. If your project needs to be inspected or hold heavy things, traditional welding is a good choice.

Note: Traditional welding is best for thick materials and important jobs. You get strong welds that meet industry rules.

Speed and Efficiency

Laser Welding Speed

You want your project to finish quickly. Laser welding helps you save time. This method uses a focused beam to join materials fast. You can complete jobs much faster than with older welding methods. In factories, laser welding is about four times faster than TIG welding. It is also twice as fast as MIG welding. You can see the difference when you need to make many parts or finish a big job.

- Laser welding systems are easy to use. You spend less time training workers.

- The process makes clean welds. You do not need to fix mistakes or clean up much after.

- Handheld laser welders let you work in many places. You can start jobs quickly and move from one task to another.

- You finish projects faster and can take on more work.

Tip: If you want to speed up your project and get neat results, laser welding is a smart choice.

Traditional Welding Speed

Traditional welding methods like MIG, TIG, and Stick take more time. You need to set up the equipment and train workers for each type. TIG welding is slow because you must guide the torch and add filler by hand. MIG welding is faster than TIG, but it still needs careful setup and clean metal. Stick welding works well outside, but it is the slowest and needs cleaning after each weld.

- You spend more time preparing the metal and cleaning up after.

- Training takes longer for new workers.

- You may need to redo welds if there is too much spatter or mistakes.

Traditional welding is a good choice for thick materials and outdoor jobs. If you do not need to finish quickly, these methods work well. You get strong welds, but you must plan for longer project times.

Cost Factors

Equipment and Setup Costs

When you plan a welding project, you must think about costs. Laser welding machines are much more expensive than traditional ones. You pay more because laser welding uses advanced technology. Traditional welding, like MIG or TIG, costs less to start. You can pick a simple setup or pay more for extra features.

| Category | Laser Welding | Traditional Welding (TIG, MIG) |

|---|---|---|

| Initial Investment | $30,000 – $500,000+ | $2,000 – $5,000 (basic setup) |

| $10,000 – $50,000 (advanced) | ||

| Energy | $3,000 – $6,000 | $1,000 – $3,000 |

| Consumables | $1,500 – $7,000 | $5,000 – $15,000 |

| Maintenance | $1,000 – $25,000 | $500 – $2,500 |

| Facility Modifications | $500 – $1,000 | N/A |

| Installation Fees | N/A | N/A |

You might need to change your workspace for laser welding. Safety covers and better air systems can cost $500 to $1,000 more. You may also pay more for a pro to set up your laser machine. For traditional welding, you do not need these changes.

Tip: If you want to spend less at first, pick traditional welding. Laser welding costs more but gives you special features.

Operating Expenses

After you buy your welding machine, you still have to pay for other things. You need to pay for energy, supplies, and fixing your machine. Laser welding uses fewer materials and works faster. This means you spend less on repairs and waste. You make fewer mistakes and your machine does not break as much. If you take care of your laser welder, it will last longer and need less fixing.

Traditional welding needs more care and fixing. You spend more on gas and safety gear. You have to fix the machine more often, which can cost more over time. Some new machines can tell you when they need repairs. This helps you save money and time.

- Laser welding costs more to fix but lasts longer.

- Traditional welding needs more repairs and uses more supplies.

- Laser welding saves money by making less waste and working faster.

Note: If you want to save money in the long run, laser welding can help. Traditional welding is cheaper at first but can cost more later.

Ease of Use

Training for Laser Welding

Learning laser welding is not very easy. The machines use advanced technology. You need special training to use them safely. The controls are hard to understand. You must know how to set the laser for each job. Many companies want you to take classes first. You may need to work with a skilled technician before starting.

- You need special training because the machines are tricky.

- You must learn safety rules for strong light beams.

- You spend more time learning than with older welding.

Tip: If you want to use laser welding, plan for extra training. You must learn new skills before working alone.

Skill for Traditional Welding

Traditional welding methods are easier for most people. You can start with basic lessons and simple projects. Many schools and workshops teach these methods. You do not need to know about complex machines. You can learn the basics quickly. You get better as you practice.

Here is a quick look at how learning compares:

| Aspect | Traditional Welding | Laser Welding |

|---|---|---|

| Learning Curve | Easier for new technicians | Needs special training |

| Familiarity | Well-known and used for years | Newer technology, less familiar |

| Training Requirements | Simple, easy to train | Complex, needs skilled technicians |

| Initial Investment | Lower equipment costs | Higher costs for equipment and training |

| Automation | Easier to automate | Harder to automate |

Note: You can learn traditional welding faster. You do not need to spend much money or time on training. Many people start with stick welding because it is simple.

If you want to start welding soon, traditional methods may be best. You can build your skills step by step. You can work on many types of projects.

Material Compatibility

Best Materials for Laser Welding

Laser welding works on many kinds of materials. It is good when you want clean and strong joints. You get better results if you pick the right material. You also need to prepare the joint before welding. Some materials that work well are:

- Stainless steel

- Carbon steel

- Aluminum

- Copper

- Alloy steel

- Titanium

- Plastics

Laser welding makes neat seams and is fast with these materials. You should check how thick the pieces are. Thin and medium-thick pieces work best. The joint must be clean before you start. If the material is thick or the joint is not ready, you may have problems. You need special training to use the machine safely and get good welds.

Tip: You get the best welds with thin or medium-thick metals. Make sure the joint is clean and ready.

Best Materials for Traditional Welding

Traditional welding works on many metals. It is good for thick pieces and strong joints. People use these methods for building, repairs, and heavy equipment. The table below shows which metals fit each method:

| Material | Characteristics | Suitable Welding Methods |

|---|---|---|

| Steel | Strong, bendable, and cheap; comes in stainless, carbon, and low-carbon | Stick, flux wire, gas metal arc, resistance spot, DC-TIG |

| Cast Iron | Melts at low heat; used for bridges, fences, and kitchen tools | Stick welding |

| Other Metals | Need special ways; includes magnesium alloys, brass, copper, titanium | AC-TIG for magnesium, DC-TIG for brass, copper, titanium |

You can weld steel with almost any method. Cast iron is best with stick welding. For magnesium, brass, copper, or titanium, you need TIG welding with the right settings. These methods give you strong and safe joints.

Note: Pick the welding method that matches your material and project. You get better results if you use the right process for each metal.

Safety and Distortion

Safety Considerations

You must always think about safety when you weld. Laser welding and traditional welding both have risks, but the dangers are not the same. Laser welding uses a powerful beam of light. This can hurt your eyes and skin if you do not use the right gear. You also need to watch out for gases and fumes. Traditional welding has its own risks, like burns, electric shock, and breathing in smoke.

Here is a table that shows the main safety risks for laser welding:

| Safety Risk | Description |

|---|---|

| Radiation | Powerful infrared and ultraviolet light can damage your skin and eyes. |

| Skin Burns | The laser gets very hot and can burn you or melt metal onto your skin. |

| Eye Damage | Looking at the laser or its reflection can cause vision loss. |

| Compressed Gas Risks | Shielding gases can explode or cause you to stop breathing if not handled right. |

| Electrical Hazards | High-voltage parts can shock you if you do not check them often. |

| Fire Hazards | The heat from the laser can start fires if things nearby catch fire easily. |

| Toxic Fumes | Melting metal makes fumes that can hurt your lungs. |

| Mechanical Hazards | Machines can trap or crush your hands if you do not stay alert. |

Tip: Always wear safety glasses, gloves, and the right clothes. Make sure your work area has good airflow and no flammable items nearby.

Heat-Affected Zone and Distortion

When you weld, the heat changes the metal around the weld. This area is called the heat-affected zone (HAZ). Laser welding gives you a much smaller HAZ. The laser moves fast and heats only a tiny spot. This means the rest of your metal stays cool and strong. You get less bending and warping.

Traditional welding, like MIG or TIG, heats a bigger area. The metal cools down slowly, so the HAZ is wider. This can make your metal softer or harder in spots, and it can bend or twist more. You may need to fix the shape after you finish welding.

Note: If you want your project to keep its shape and strength, laser welding is a better choice. You get less heat damage and a cleaner finish.

Weld Appearance

Visual Finish

You want your welds to look clean and smooth. Laser welding gives you a very neat finish. The laser makes a thin, even seam. You see almost no spatter or rough spots. The weld line is narrow and shiny. You often do not need to grind or polish the joint.

Traditional welding, like MIG or TIG, can leave more marks. You may see spatter, bumps, or a wider bead. Stick welding often leaves slag on top of the weld. You must chip or brush this away. TIG welding gives a cleaner look than MIG or Stick, but it still may not match the smoothness of laser welding.

Here is a quick comparison:

| Feature | Laser Welding | Traditional Welding (MIG, TIG, Stick) |

|---|---|---|

| Seam Width | Very narrow | Wider |

| Spatter | Minimal | Moderate to high |

| Surface Smoothness | High | Varies |

| Need for Cleaning | Low | Moderate to high |

Tip: If you want a weld that looks almost invisible, laser welding is your best choice.

Post-Weld Processing

After welding, you may need to clean or finish the joint. Laser welding saves you time here. The weld is so clean that you often skip grinding or sanding. You can move straight to painting or assembly.

With traditional welding, you usually need more steps. You may have to remove slag, grind the bead, or sand the surface. These steps take extra time and effort. If you want a smooth finish, you must work longer.

- Laser welding: Less cleanup, faster finishing.

- Traditional welding: More cleanup, more time needed.

Note: Laser welding helps you finish projects faster because you spend less time on post-weld work.

Choosing the Right Method

Project Checklist

You want to choose the best welding method. Use this checklist to help you decide. Go through each point and see what fits your project.

- Material Type and Thickness

Look at what metal or material you have. Laser welding works well for thin metals. Traditional welding is better for thick metals. - Required Weld Quality and Appearance

Think about how neat and strong you want your welds. Laser welding gives a smooth and clean look. Traditional welding is good for strong welds. - Production Volume and Speed

Decide how many parts you need to weld. Laser welding is fast for big jobs. - Budget and Cost Structure

Check your budget. Laser welding costs more at first. It can save money later. Traditional welding costs less to start. - Joint Tolerance and Accuracy

See if you need tight joints and exact fits. Laser welding helps with small gaps. - Safety Needs

Make sure you have the right safety gear. Laser welding needs special eye protection. Traditional welding needs gloves and good airflow. - Utilities and Workspace

Check if you have enough power and gas. Laser welding may need extra equipment. - Inspection and Quality Control

Plan how you will check your welds. Laser welding can track seams as you work. Traditional welding may need checking after you finish. - Changeover and Flexibility

Think about how often you switch jobs. Laser welding changes programs and optics. Traditional welding swaps torch tips and nozzles.

Tip: Go through each checklist item. Match your project needs with the right welding method. This helps you avoid mistakes and get better results.

Common Misconceptions

Here is a table that clears up some myths about welding:

| Misconception | Fact |

|---|---|

| Laser welding is not versatile | You can use laser welding on many materials like aluminum, copper, and glass. |

| Laser welding is less precise | Laser welding gives you higher precision and less material deformation. |

| Laser welding is more expensive | Laser welding saves money with less waste and faster welding times. |

Example Scenarios

You can see how different projects use each welding method. Here are some real examples:

- Car factories use laser welding for chassis and battery parts. This makes work faster and more exact, especially for electric cars.

- Aerospace companies use laser welding for titanium and light alloys. This gives strong and steady welds.

- Electronics makers use laser welding for tiny sensors and circuits. It helps them get small, exact welds and avoid heat damage.

- Medical device makers use laser welding for tools and implants. The welds are clean and meet safety rules.

Other projects use traditional welding:

- Construction teams use MIG and Stick welding for thick steel beams and outdoor repairs. These methods make strong joints and work well outside.

- Heavy equipment repair shops use Stick welding for cast iron parts. This method works for thick and rough materials.

- Metal furniture makers use MIG welding for fast work and strong welds.

Note: Experts say you should look at your material thickness, design needs, and weld quality before you choose. Laser welding is best for thin materials and jobs that need high precision. Traditional welding is better for thick materials and strong, flexible joints.

Quick Reference Table

| Project Type | Best Welding Method | Why? |

|---|---|---|

| Thin, precise electronics | Laser welding | High accuracy, minimal heat damage |

| Medical implants/tools | Laser welding | Clean welds, meets safety standards |

| Car body panels | Laser welding | Fast, neat, strong joints |

| Thick steel beams | Traditional welding | Handles heavy materials, strong welds |

| Outdoor repairs | Traditional welding | Works in tough conditions |

| Metal furniture | MIG welding | Fast, cost-effective |

Tip: Use this table to match your project with the right welding method. You get better results when you choose based on your needs.

You can make the best choice by using your checklist and these examples. This helps you finish your project faster and with better quality.

You can spot big differences between laser welding and traditional welding. Laser welding is more exact. It works faster and causes less heat damage. Traditional welding is better for thick pieces and most jobs.

| Feature | Traditional Welding | Laser Welding |

|---|---|---|

| Precision | Lower | Higher |

| Speed | Slower | Faster |

| Thin Metals | Less suitable | Highly suitable |

Laser welding is best for thin and fragile parts. It is also good when you want to finish quickly. Traditional welding is best for thick metals. If you want more help, look at the American Welding Society’s resources.

FAQ

What materials work best with laser welding?

You get the best results with stainless steel, aluminum, titanium, and thin metals. Laser welding also works on plastics. You should use clean and flat surfaces for strong joints.

Is laser welding safe for beginners?

Laser welding needs special training. You must wear safety glasses and protective clothing. You should learn safety rules before you start. Beginners should work with a trained technician.

Can you use traditional welding outdoors?

You can use stick welding outdoors. It works well in windy or dirty places. MIG and TIG welding need clean conditions, so you should use them inside.

Does laser welding cost more than traditional welding?

Laser welding costs more at first. You pay for advanced equipment and training. You save money later because you finish jobs faster and use fewer supplies.

Comparison of efficiency between laser cleaning and manual polishing

Laser cleaning vs. dry ice cleaning: which is more environmentally friendly

Which Cleaning Method Wins Fiber Laser or Ultrasonic

How to Adjust Galvanometer Scanning Speed for Superior Cleaning