Download product brochure

Download our product series documentation for detailed technical information and frequently asked questions. We can also provide you with customized solutions.

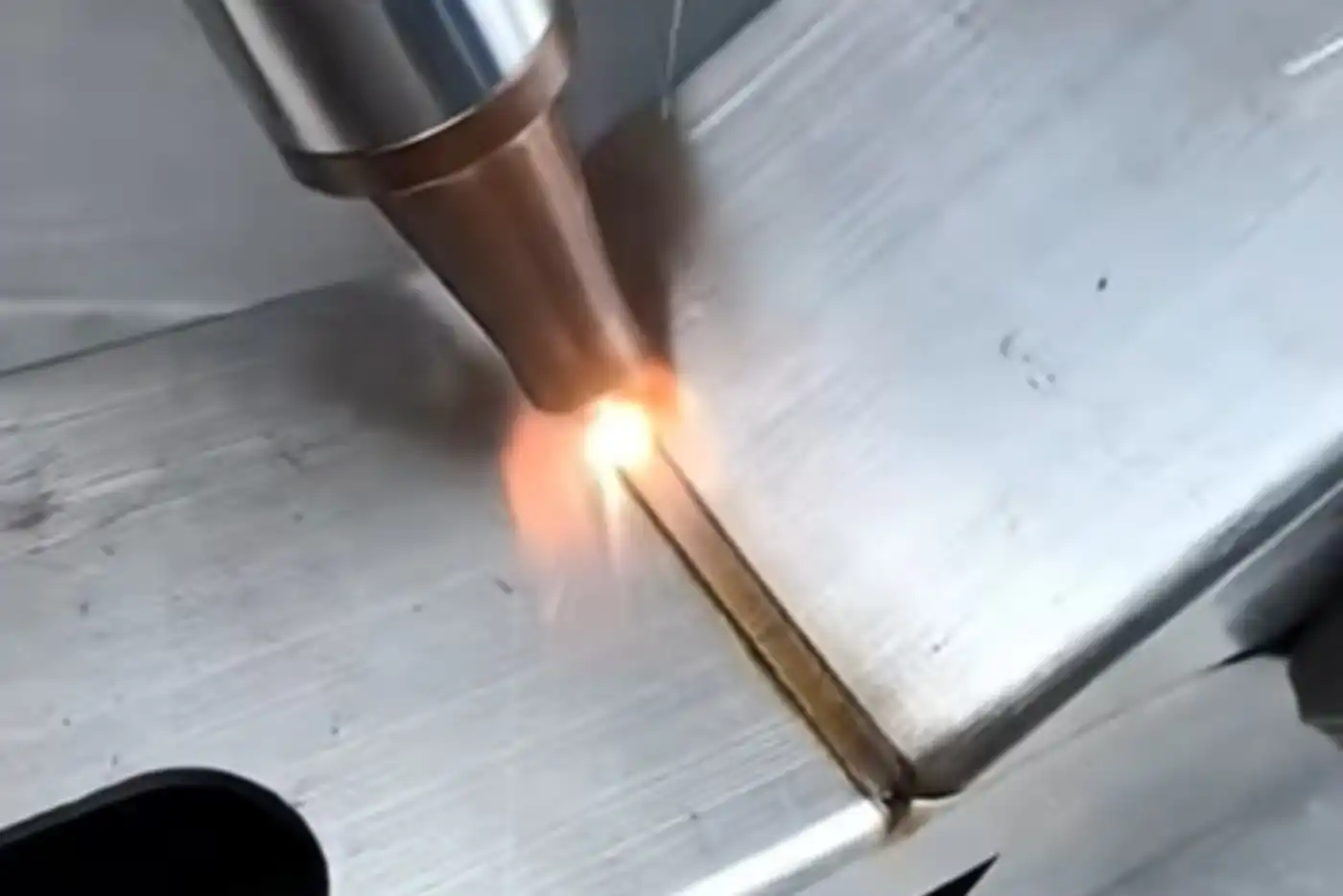

Laser welding

Are you still troubled by the low efficiency, unsightly welds, and significant thermal impact of traditional welding methods? Cofen Laser provides you with professional laser welding solutions. We use advanced fiber laser technology to achieve high-precision, high-speed, and low deformation welding effects, suitable for various metal materials such as stainless steel, aluminum alloy, carbon steel, etc. Whether it’s precision welding of complex structural components or automated welding on mass production lines, Coffin can provide you with an efficient, stable, and environmentally friendly welding experience.

Our service advantages

We are not only a supplier of handheld laser welding equipment, but also your trusted technical partner. Oceanplayer combines advanced fiber laser welding technology with years of industry experience, and has a professional team of engineers who can provide customized solutions based on your workpiece material, welding method, and production scenario. We are committed to making every welding precise, firm, and aesthetically pleasing, while significantly improving production efficiency, ensuring weld quality and material integrity, and bringing you an efficient, intelligent, and reliable laser welding experience.

Efficient and flexible welding

Handheld design makes operation more convenient and can easily handle large workpieces, irregular shapes, or outdoor work scenarios. No need for fixed fixtures, flexible and versatile welding positions, greatly improving production efficiency and operational freedom.

Deep penetration welding effect

Using high-power fiber laser technology, the welding depth is large, the strength is high, and the weld seam is dense. It can easily achieve high-quality connections to metals such as stainless steel, aluminum alloy, and carbon steel, ensuring a firm and reliable welding effect.

Smooth and beautiful weld seam

Laser heat input is small, deformation is low, and the weld seam does not require excessive polishing treatment. The appearance is smooth and delicate, without obvious welding marks, effectively reducing the later polishing process and improving the overall appearance and product quality of the workpiece.

Energy-saving design

No need for welding wire or additional solder, low energy consumption, minimal smoke and dust, almost no noise or splashing during operation, reducing material waste and creating a more environmentally friendly, clean, and safe working environment.

Core products and application areas

We focus on the research and manufacturing of laser welding technology, committed to providing efficient and high-quality metal connection solutions for various industries. The Kefeng handheld laser welding machine has the advantages of firm welding, flexible operation, low thermal impact, and easy maintenance, and can be widely used for various metal materials such as stainless steel, aluminum alloy, carbon steel, etc. With advanced fiber laser technology, Kefeng helps customers achieve more efficient, aesthetically pleasing, and environmentally friendly welding processes, assisting enterprises in building intelligent and high-quality production systems.

- High precision welding

- Maintenance free, no consumables

- Fast and efficient performance

- Environmentally friendly manufacturing process

- Flexible and applicable to multiple industries

- Intelligent control and easy operation

Our handheld laser welding machine is widely used in industries such as stainless steel cabinets, metal doors and windows, guardrails and handrails, kitchen equipment, automotive parts, advertising signs, mold repair, etc. It can efficiently complete various processes such as thin plate docking, corner welding, stacking welding, and filling welding. The weld seam is smooth, beautiful, firm and deformation free, reducing the need for later polishing and finishing processes. With flexible and convenient operation methods and excellent welding quality, handheld laser welding machines help enterprises achieve efficient production, reduce labor costs, and promote the transformation of manufacturing processes towards intelligence and high quality.

Popular questions

What are the advantages of handheld laser welding machines compared to traditional argon arc welding?

Laser welding has faster speed, more beautiful welds, smaller heat affected zone, and almost no need for polishing treatment. At the same time, it has lower energy consumption, simpler operation, and more convenient maintenance, greatly improving production efficiency.

Is it difficult to operate a handheld laser welding machine? Do you need professional skills?

The operation is very simple, and most users can get started after 1-2 hours of basic training. The equipment is equipped with intelligent control system and safety protection design, with intuitive operation, safety and reliability.

Is welding wire required during the welding process?

According to the process requirements, you can choose between the “silk” or “no silk” mode. For workpieces with larger gaps or requiring higher strength, it is recommended to use a wire feeding system to ensure firm welding.

Will handheld laser welding cause deformation or burn through?

Compared to traditional welding, laser heat input is small, welding is more concentrated and controllable, and there is basically no significant deformation or burn through problem, especially suitable for thin plates or high-precision workpieces.

How long is the service life of a laser welding machine?

The lifespan of fiber lasers usually exceeds 100000 hours, and the overall design of the equipment is stable and reliable. Under normal maintenance, it can operate efficiently for a long time, greatly reducing maintenance costs.

Can handheld laser welding machines be used for outdoor or large workpieces?

Absolutely possible. Its lightweight design and flexible operation make it particularly suitable for large workpieces, fixed equipment, or outdoor construction scenarios, with easy mobility and flexible operation.

How to choose the power of a handheld laser welding machine?

Common powers include 1000W, 1500W, 2000W, 3000W, etc.

For general thin plates, 1000-1500W is recommended, while for medium thick plates, 2000W or more is recommended. The specific amount needs to be determined based on the material thickness and production requirements.