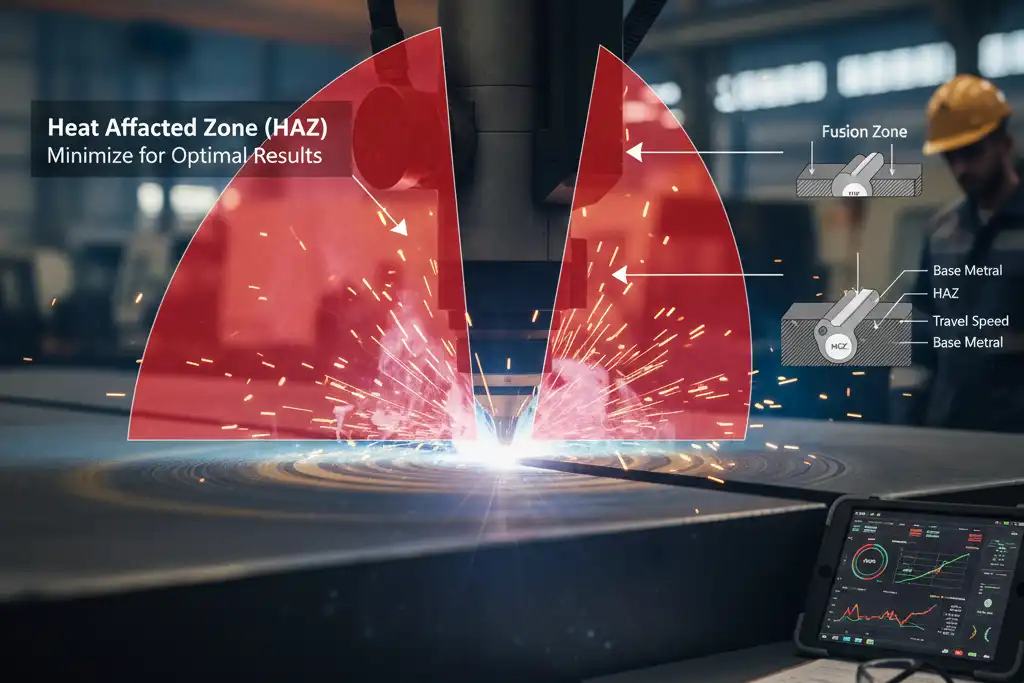

The heat affected zone (HAZ) in laser welding is the part of the metal next to the weld. This area gets hot but does not melt. You should watch the HAZ because it can change how strong or tough the welded joint is. The HAZ can make the metal harder or softer. It may also make the metal more likely to crack or rust.

| Impact Factor | Description |

|---|---|

| Microstructural Changes | The HAZ goes through grain growth and phase changes. This can change how strong the metal is. |

| Hardness Variations | Hardness can go up or down. This can make the metal brittle or weak. |

| Residual Stresses | These stresses can make the metal less able to handle repeated use. They can also start cracks. |

| Corrosion Susceptibility | The HAZ can get rusty more easily. This makes the metal not last as long. |

| Toughness Reduction | The HAZ can lose its ability to take hits. This makes it easier to break. |

Key Takeaways

- The heat affected zone (HAZ) is the area next to the weld that gets hot but does not melt. It can change the strength and toughness of the metal.

- Factors like laser power, welding speed, and metal type affect the size of the HAZ. Higher power or slower speed increases the HAZ size.

- Inspect the HAZ after welding to identify issues like cracks or brittleness. This ensures the weld remains strong and reliable.

- Use cooling methods and adjust laser settings to minimize the HAZ. This helps maintain the metal’s strength and prevents defects.

- Understanding the HAZ is crucial for creating strong welds. Control it well to avoid problems like cracking and rust.

HAZ Definition in Laser Welding

What is the heat affected zone

When you use laser welding, the heat affected zone (HAZ) is the part of the metal that gets hot but does not melt. This area sits right next to the melted part of the weld. The HAZ is important because it changes when exposed to high temperatures. According to welding standards, the HAZ is the region of the base material that stays solid during welding but still goes through changes in its properties. You might see the metal become harder or softer in this area. The HAZ can also show different levels of toughness and strength compared to the rest of the metal.

Note: The HAZ in laser welding is crucial because it defines the area of the base material that remains solid but experiences changes in its material properties due to high temperature exposure.

You can think of the HAZ as a border zone. It does not melt like the fusion zone, which is the part that turns liquid and then solidifies. The HAZ only gets hot enough to change its structure. The rest of the metal, called the unaffected base material, keeps its original properties.

- The HAZ does not melt like the fusion zone.

- The HAZ experiences changes in material properties due to high temperatures.

- The fusion zone is where the material melts and solidifies, while the unaffected base material keeps its original properties.

- The HAZ can show altered hardness and toughness.

- Residual stress levels in the HAZ can affect how strong the welded part is.

Where the HAZ occurs

You will find the HAZ right next to the weld bead in laser welding. The weld bead is the line or area where the metal has melted and joined together. The HAZ forms in the area that surrounds this bead. In laser welding, the HAZ is usually small. This happens because the laser works quickly and focuses heat in a tight spot. Less heat spreads out, so the HAZ does not get very wide.

- The HAZ is the area that has not melted but has changed because of high temperatures.

- In laser welding, the HAZ is typically small because the process is fast and focused.

- This small HAZ sits right next to the weld bead, in the area around the weld that has been affected by heat.

The width of the HAZ can change. If you use lower laser power, the HAZ gets smaller. If you move the laser farther from the surface, the HAZ can get wider. You should always check where the HAZ is because it can affect how strong and tough your welded part will be.

Formation and Influencing Factors

How the HAZ forms

When you use laser welding, the heat affected zone forms because the metal near the weld gets very hot. This heat does not melt the metal, but it changes the way the metal looks and acts. The heat causes the grains in the metal to grow larger. In some metals, you might see the structure change from one type to another. For example, in special alloys like NiTi, the structure can change from austenitic to martensitic, and small particles can form at the grain edges. These changes happen because the heat from the laser moves quickly through the metal.

The size and severity of the HAZ depend on how fast heat moves through the metal. Metals like stainless steel have a narrow HAZ because heat does not travel quickly. Metals like copper and aluminum have a wider HAZ because heat spreads out faster.

Factors affecting HAZ size

Several things decide how big the HAZ will be. You can see the main factors in the table below:

| Factor | Description |

|---|---|

| Laser Power | More power means more heat, which makes the HAZ bigger. |

| Welding Speed | Faster welding gives the metal less time to heat up, so the HAZ is smaller. |

| Focus Position | Changes in focus can make the heat spread out more or less. |

| Pulse Characteristics | The way the laser pulses can change how much heat goes into the metal. |

- If you use high laser power, the HAZ gets bigger.

- If you weld quickly, the HAZ gets smaller.

- The way you focus the laser and the type of pulse you use also matter.

Role of material properties

The type of metal you use changes the HAZ. Metals with high thermal conductivity, like aluminum, let heat move fast, so the HAZ gets wider. Stainless steel has low thermal conductivity, so the HAZ stays narrow. The thickness of the metal also matters. Thicker metals can spread heat more, which can change the HAZ size.

- High thermal diffusivity means the HAZ cools quickly and stays narrow.

- Low thermal diffusivity means heat stays longer, making the HAZ wider.

- Aluminum has a much higher thermal conductivity than stainless steel, so you see a bigger HAZ in aluminum.

If you know what kind of metal you are working with, you can guess how the HAZ will look and how it might affect your weld.

Effects on Material Properties

Changes in strength and hardness

When you use laser welding, the heat affected zone changes the strength and hardness of the metal. You will notice that the HAZ can become either harder or softer than the base metal. This happens because the metal cools at different rates in different areas. Sometimes, the HAZ gets stronger, but it can also lose ductility, which means it does not bend as easily. Here are some common changes you might see:

- The laser melts and fuses metal pieces, but most of the heat stays close to the weld, so the HAZ is small.

- If more heat spreads into the HAZ, the metal can become brittle, which lowers the tensile strength.

- Microhardness tests show that the HAZ and fusion zone often have higher strength, but the welded joint may not stretch as much as the original metal.

- Hardness can change in the HAZ. Softer spots may not hold heavy loads, while very hard spots can crack under stress.

Brittleness and corrosion resistance

The HAZ can also affect how brittle the metal is and how well it resists rust. You may see the following effects:

| Description | Impact |

|---|---|

| The HAZ can soften, which lowers yield strength and makes the metal break more easily. | Increased brittleness |

| Fast heating and cooling in laser welding can make the HAZ more brittle than with other welding methods. | Higher risk of brittle failure |

| Very quick cooling can create brittle structures in the HAZ. | More likely to crack |

The HAZ can also lower corrosion resistance. Changes in the metal’s structure can make it rust faster, especially in tough environments like aerospace or oil and gas.

- The HAZ can change the microstructure and reduce strength.

- You may see more brittleness and less corrosion resistance in the HAZ.

Impact on weld integrity

The HAZ plays a big role in how strong and reliable your weld is. You need to watch for changes in the HAZ because they can lead to problems like cracks or weak spots. Here is what you should know:

- The HAZ changes its structure when heated, which affects strength, ductility, and how well the weld holds up over time.

- Factors like laser power, welding speed, and the type of metal all change the HAZ.

- If you do not control the HAZ, you might see defects such as cracks, porosity, or even burn-through.

Tip: Always check the HAZ after welding to make sure your joint is strong and free from defects.

Evaluating and Minimizing HAZ in Laser Welding

Inspection and testing methods

There are different ways to check the heat affected zone in laser welding. These ways help you see if the metal is harder or softer, find cracks, and notice changes in the metal’s structure. The table below lists some common ways to inspect the HAZ:

| Inspection Method | Description |

|---|---|

| Microhardness Testing | Checks how hard the weld bead, HAZ, and base metal are. This helps find spots that might have problems. |

| Visual Inspections | Looks for cracks or color changes on the surface. These can show if the metal got too hot. |

| Metallurgical Analysis | Uses a microscope to look at grain changes in the HAZ. This shows if the metal is still strong. |

Non-destructive testing (NDT) lets you find problems in the HAZ without breaking the weld. You can use visual tests to find cracks on the surface. Magnetic particle testing finds small cracks in metals that stick to magnets. Ultrasonic testing finds deep cracks inside the metal. Each test has things it does well and things it cannot do. For example, ultrasonic testing finds inside cracks but needs someone trained to use it.

Strategies to reduce HAZ

You can do things to make the HAZ smaller and get better welds. Here are some ideas:

- Change the laser’s power, speed, and focus to control the heat.

- Warm up the metal before welding to keep the temperature steady.

- Use cooling, like water or special gas, to slow down cooling and stop the metal from getting brittle.

- Use gases like argon or carbon dioxide to keep the weld clean and stop rust. Argon makes the weld stronger. Carbon dioxide helps the weld bend more.

Tip: Cooling with liquid nitrogen and using the right amount of shielding gas can help keep the HAZ small and the weld strong.

Application-specific considerations

Different jobs need special ways to control the HAZ. In car making, you must think about what the metal is made of, how much carbon it has, and how fast it cools. Warming up the metal and changing welding settings help stop cracks and control changes in the metal. The table below shows important things for car welding:

| Consideration | Description |

|---|---|

| Material Properties | What the metal is made of, like how much carbon, changes how easy it is to weld and how the HAZ looks. |

| Pre-heating | Warming up the metal slows cooling and helps stop cracks in the HAZ. |

| Carbon Content | More carbon makes the HAZ easier to break, so you need to be careful. |

| Cooling Rate | How fast the metal cools changes what forms in the HAZ and how strong the weld is. |

| Experimental Parameters | You need to test different settings for each metal and shape to get the best weld. |

In airplanes, you must keep the HAZ small to make sure the metal stays strong and safe. You should look for problems using visual checks and microscopes. Controlling how much energy you use and how well the metal moves heat helps stop the weld from bending or breaking.

You should know about the heat affected zone (HAZ) in laser welding. This helps you make welds that are strong and last longer. If you control the HAZ well, you can stop problems like bending, cracks, and breaking. Here are some simple tips you can use:

- Change the laser’s power, speed, and focus to make the HAZ smaller.

- Check and test your welds so you can find problems early.

- Use cooling and pulse welding to help control the heat.

New tools make it easier to control the HAZ:

| Advancement Type | Description |

|---|---|

| Fiber Laser Modules | Give focused energy and make the HAZ smaller. |

| Beam-Shaping Optics | Help you control the laser and stop the metal from bending. |

| Intelligent Control Systems | Let you watch and change settings while you weld. |

Try these steps in your work to get better welds and stronger metal.

FAQ

What is the main purpose of the heat affected zone in laser welding?

You see the heat affected zone because the metal near the weld gets hot. This area does not melt but changes in structure. The HAZ shows you where the metal’s properties may differ from the rest.

What problems can the HAZ cause in welded parts?

You might find cracks, brittleness, or rust in the HAZ. These problems can make your weld weaker. Always check the HAZ to keep your weld strong and safe.

What makes the HAZ bigger or smaller?

Laser power, welding speed, and the type of metal change the HAZ size. High power or slow speed makes the HAZ bigger. Fast welding or low power keeps it small.

What can you do to control the HAZ during laser welding?

You can adjust the laser’s power and speed. Use cooling methods or shielding gas. These steps help you keep the HAZ small and protect the metal’s strength.

What you should know about CNC machine tools and laser cutting

6 Downsides of Laser Welding for Manufacturers