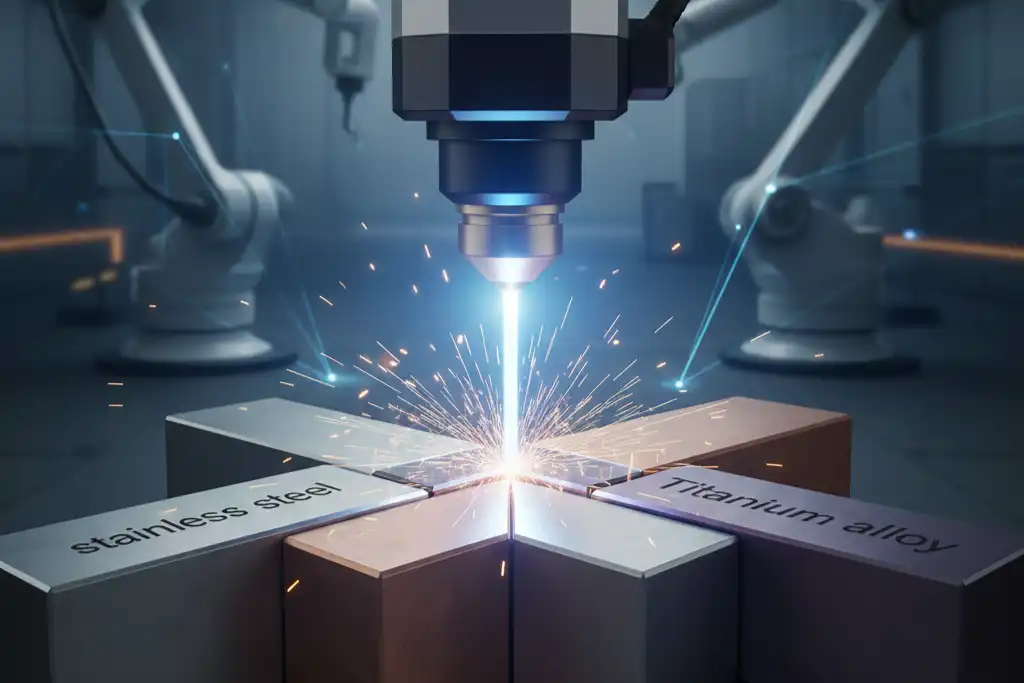

You can use laser welding on many metals. Some common metals are stainless steel, carbon steel, alloy steel, die steel, aluminum (mostly the 6000 series), copper, titanium, nickel alloys, and precious metals. Each metal acts in its own way during welding. The table below lists the main metals used in laser welding for making things:

| Metal | Description |

|---|---|

| Stainless Steel | People use it a lot because it welds very well. |

| Titanium | It is needed in planes and medicine for its strength and safety. |

| Aluminum | It is picked for being light and good at carrying electricity, but it is tough to weld. |

You can see that every metal has good points and hard parts. Laser welding is very exact and does not bend the metal much. This makes it great for special alloys and parts that need care.

Key Takeaways

- Laser welding can join many metals like stainless steel, aluminum, and titanium. Each metal is different and this changes how welding works.

- Preheating is very important for high-carbon and alloy steels. It stops cracks and makes welds stronger.

- Always clean the metal before you start welding. Cleaning helps stop problems and makes the weld better.

- Pick the right filler for aluminum so it does not crack. The 6000 series aluminum needs special fillers for strong welds.

- Change laser settings for the metal’s thickness and type. Each metal needs its own power and speed for best results.

Steel Alloys for Laser Welding

Stainless and Carbon Steel

You can use laser welding on many types of steel. Stainless steel is one of the most popular choices. It works well because it resists rust and keeps its strength after welding. You will find several families of stainless steel, and each one acts differently when you weld it. The table below shows what you need to know:

| Stainless Steel Family | Weldability | Thermal Expansion | Thermal Conductivity | Additional Notes |

|---|---|---|---|---|

| Austenitic | Excellent | High | Low | Prone to distortion |

| Ferritic | Moderate | Low | Moderate | Risk of grain growth |

| Martensitic | Difficult | Moderate | Low | High risk of cold cracking |

| Precipitation-Hardening (PH) | Good | Moderate | Moderate | Depends on heat treatment |

| Duplex | Good | Moderate | Moderate | Sensitive to phase imbalance |

You should know that austenitic stainless steel is the easiest to weld. It does not crack easily, but it can bend or twist because it expands a lot when heated. Ferritic and martensitic types need more care. They can crack or grow large grains if you do not control the heat. Duplex and PH stainless steels also work well, but you must watch the heat and cooling steps.

When you weld carbon steel, you must pay attention to the amount of carbon in the metal. The carbon content changes how hard, strong, and flexible the steel becomes. It also affects how easy it is to weld. Here is a simple breakdown:

- Low-carbon steel (0.05% to 0.25% carbon): You will find this type easy to weld. It stays flexible and does not crack much.

- Medium-carbon steel (0.30% to 0.50% carbon): This type balances strength and flexibility. You may need to preheat it before welding.

- High-carbon steel (0.60% to 1.00% carbon): This steel is very strong and hard. It can crack if you do not preheat and cool it slowly.

Tip: If you work with high-carbon steel, always check the Carbon Equivalent (CE) value. A high CE means you must preheat and sometimes treat the weld after you finish.

You will often see laser welding used for stainless and low-carbon steels in industries like food processing, medical tools, and construction. These metals give you strong, clean welds with little extra work.

Alloy and Die Steel

Alloy steel and die steel are special types of steel that have extra elements like chromium, nickel, or molybdenum. These elements make the steel stronger or more resistant to wear. You can use laser welding on these steels, but you must follow some rules to get good results.

- Preheating is very important. You should heat the steel to about 100-150 °C before you start welding. This step helps stop cracks from forming.

- The right preheating temperature depends on the carbon and alloy content, the thickness of the metal, how fast you weld, and even the temperature in your workspace.

- If you skip preheating, you may see cold cracks or weak welds.

You will find laser welding of alloy and die steels in many industries:

- Automotive: You can join steel parts in cars and trucks. The welds are strong and precise.

- Aerospace: You need high-quality welds for airplane parts. Laser welding gives you clean joints with little heat damage.

- Heavy machinery: You can keep big machines strong by welding thick steel parts with this method.

- Manufacturing: You get high-quality welds with little bending or warping.

Note: Always check the type of steel and its carbon or alloy content before you start. This step helps you choose the right preheating and welding settings.

Laser welding gives you many options for joining steel alloys. You can make strong, neat welds if you match your process to the type of steel you use.

Aluminum and Laser Welding

6000 Series and Filler Material

Aluminum is used a lot in cars, planes, and electronics. The 6000 series aluminum alloys are strong and easy to shape. Laser welding can join these alloys, but you must use the right filler material. The filler stops cracks and makes the weld strong.

Here is a table that shows which filler materials work best for 6000 series aluminum:

| Filler Material | Type |

|---|---|

| 4045 | Suitable |

| 5356 | Suitable |

Pick the filler based on the alloy and the job you have. The right filler keeps the weld from cracking and gives a smooth finish.

Tip: Always check the alloy number before you start welding. Using the wrong filler can make the weld weak or cause cracks.

Welding Challenges

Aluminum has some problems when you use laser welding. You need to know what makes it different from other metals.

- Aluminum reflects a lot of the laser beam. This makes it hard for the metal to get enough energy for a deep weld.

- Aluminum spreads heat very fast. You must control the heat to keep the weld pool steady.

- An oxide layer forms on the surface and blocks the laser. You need to clean the metal before welding to stop defects.

- Tiny holes called porosity can form in the weld. These holes make the joint weaker and less safe.

- The pieces must fit together tightly. Laser welding cannot fill big gaps, so you must prepare the parts well.

- Cracks and bending can happen because aluminum cools quickly. You need to watch how fast it cools to stop these problems.

- The filler material must match. The wrong filler can cause cracks or weak spots.

You can use some ways to control heat and make better welds:

- Change the laser power, speed, and focus to control heat.

- Use pulse welding to let the metal cool between bursts.

- Use cooling, like water or gas, to take away extra heat.

- Pick the right thickness for the metal. Thin pieces heat up fast and can bend.

- Control the temperature before and after welding to keep the metal even.

- Use thermal sensors to watch the weld quality. This helps you find problems early.

Note: Cleaning the aluminum before welding removes the oxide layer. This step helps the laser go deeper and gives fewer defects.

You can get strong and clean welds with aluminum if you follow these steps. Laser welding works well for aluminum, but you must pay close attention to the details.

Copper and Laser Welding

Suitability and Limitations

Copper is used in many electrical and heat jobs. It carries heat and electricity very well. Laser welding copper is tricky. Copper moves heat away from the weld very fast. This makes it hard to keep the weld hot and steady. The table below shows how copper’s features change welding:

| Property | Impact on Laser Welding |

|---|---|

| High Thermal Conductivity | Heat leaves quickly. It is hard to make a strong weld. Cracks and weak spots can show up. |

| Oxidation | Copper gets a brittle oxide layer. This can cause holes and weak welds. |

| Low Viscosity Weld Pool | Melted copper is very runny. It is hard to control the weld’s shape and spot. |

Copper also bounces back a lot of laser energy. This is true for infrared lasers. Less energy goes into the weld. You may see welds that are not steady. Fast heating and cooling can trap gases in the melted copper. This can make holes and cracks. Getting deep and even welds is tough. The keyhole can move or change shape.

Application Tips

You can get better copper welds with some special steps. Here are some tips to help you:

- Pre-heat copper to about 100℃ to 300℃. This helps lower stress and keeps the weld pool steady.

- Control how fast copper cools after welding. Slow cooling keeps copper soft and lowers stress inside.

- Use sensors to watch the weld. They help you find problems early and make sure the weld is strong.

- Try lasers with green or blue light. These help copper take in more energy and make welding steadier.

- Use beam wobble when welding. This keeps the keyhole steady and lowers holes in the weld.

- Change the laser’s power, pulse, and speed. Careful control helps stop splatter and keeps the weld even.

Tip: Clean copper before welding. Take off oxides and dirt. This helps the laser go deeper and makes a cleaner weld.

These steps help you make copper welds stronger and safer. With the right methods, you can fix copper’s problems in laser welding.

Titanium, Nickel, and Precious Metals

Laser Welding Suitability

Laser welding works for titanium, nickel alloys, and precious metals. These metals have special traits that help with careful joining. You need to think about a few things before you start:

- Material traits like absorption, conductivity, and melting point change how the metal reacts to the laser.

- Process choices like shielding gas, power, joint shape, and beam movement change how good the weld is.

- Shielding gas keeps the weld clean and stops dirt from getting in.

- Power controls how deep and strong the weld is.

- Joint shape should fit the laser for a strong weld.

- Moving the beam helps spread heat and lowers mistakes.

- Managing heat, like preheating and cooling, stops cracks in sensitive metals.

Titanium and nickel alloys take in laser energy well and melt at high heat. Precious metals like gold, silver, and platinum can be welded too. You need to change the process for each metal.

Special Considerations

You need to watch the environment and settings when welding these metals. For titanium and nickel alloys, argon is the best gas. Helium works well too. Nitrogen is not good because it can make the weld weak. You should not use nitrogen for these metals.

Tip: Always pick argon or helium for titanium and nickel alloys. This keeps the weld strong and stops bad reactions.

When you weld precious metals, set the machine to at least 6 kilowatts for silver. Do not polish the metal before welding. Leave the surface rough or tarnished to help the laser work better. If you weld jewelry with gemstones, watch the heat so you do not hurt the stones.

Here is a table for shielding gas choices:

| Metal Type | Recommended Shielding Gas |

|---|---|

| Titanium | Argon, Helium |

| Nickel Alloys | Argon, Helium |

| Precious Metals | Argon |

You can get strong and clean welds if you follow these steps. Always get the surface ready and control the heat for the best results.

Factors Affecting Weld Quality

Material Thickness and Preparation

How thick the metal is changes how well you can weld it. Thin metal needs less laser power. Thick metal needs more power to weld deep. For example, a 1 mm piece needs about 2 kW of laser power. An 8 mm piece needs up to 8 kW to weld deep and stop spatter. Each metal acts differently with laser light. Copper and aluminum reflect light and take in heat in their own way. You must change your settings for these metals.

You should always clean the metal before welding. Clean metal helps you make strong welds. Laser cleaning gives even results and does not hurt the metal. It is safe for the environment and saves money. You do not need chemicals, so you do not make extra waste. Laser cleaning also keeps the metal safe. This is important for jobs that need care.

Tip: Always clean and get your metal ready before welding. This helps you stop problems and keeps your welds strong.

Surface and Laser Settings

The surface of the metal changes how well you can weld. Dirt and rust can cause holes, weak spots, and uneven heat. Studies show clean metal has fewer holes and is stronger. If the metal is rough or dirty, the weld pool can move too much. You may not control the heat well.

Laser settings are important too. You must pick the right power, speed, and wavelength for each job. The table below shows good settings for different thicknesses:

| Material Thickness | Laser Power | Remark |

|---|---|---|

| <2 mm | 500W | Good for surface melting (conduction welds) |

| 2–5 mm | 1000–2000W | Balances heat and speed for solid penetration |

| >5 mm | 2000–3000W | Needed for deep welds and heating the base material |

Different metals need different laser settings. Stainless steel is easy because it does not move heat fast. Copper and aluminum need special settings. They take in and reflect heat in their own way.

You can check welds with tests. Looking at the weld helps you find surface problems. Radiographic and ultrasonic tests find hidden holes and cracks. Rules like EN ISO 13919-1 and ASTM E 8M-99 help you check welds the right way.

Note: Good cleaning and the right laser settings help you stop problems like cracking and holes.

You can use laser welding on many metals, but each one needs special care. The table below shows what you should know about different metals:

| Metal Type | Key Characteristics |

|---|---|

| Carbon Steel | Good welds; preheat if carbon is high. |

| Stainless Steel | Easy to weld; strong, clean joints. |

| Copper | Needs high energy and preheating. |

| Aluminum | Reflects light; needs careful prep. |

| Other Metals | Works for titanium, nickel, and more. |

You should always check thickness, surface, and fit before welding. For best results, test your welds with hardness or leak checks. When you face new jobs, talk to experts or run tests to make sure your welds are safe and strong.

FAQ

What metals work best with laser welding?

You get the best results with stainless steel, low-carbon steel, 6000 series aluminum, titanium, and nickel alloys. These metals absorb laser energy well and form strong, clean welds.

What problems can you face when laser welding aluminum?

You may see cracks, porosity, and weak joints. Aluminum reflects laser light and forms an oxide layer. You must clean the surface and use the right filler to avoid these issues.

What makes copper hard to weld with a laser?

Copper moves heat away fast and reflects most laser light. You need high power and sometimes a special laser color. Preheating and cleaning help you get better welds.

What should you check before starting laser welding?

You should check the metal type, thickness, and surface cleanliness. Make sure the parts fit tightly. Pick the right laser settings for your metal. Clean the surface to avoid defects.

Laser Cleaning Made Simple with Smart Control Tech

6 Key Reasons Your Laser Fiber Gets Damaged

Laser cleaning: which is better, air cooled or water-cooled

The influence of laser head structure design on cleaning effect