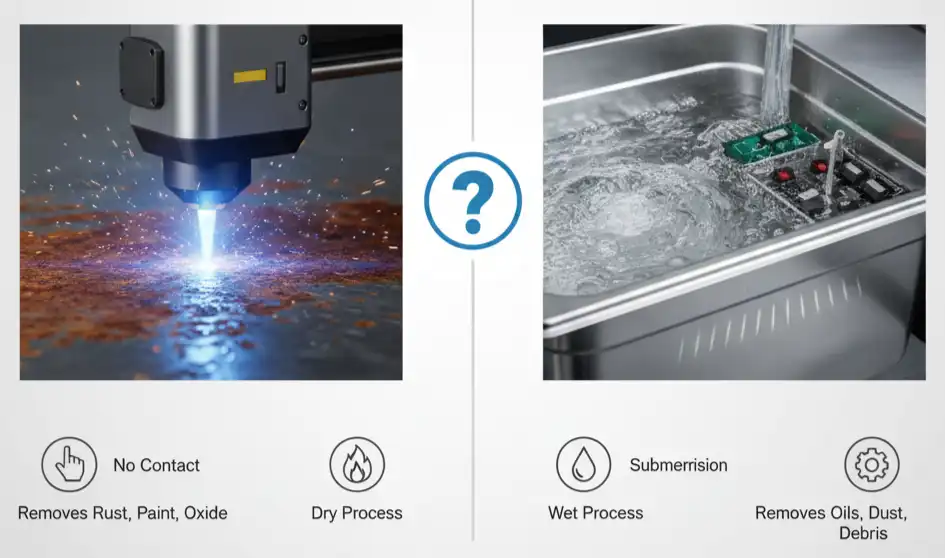

Have you ever had a hard cleaning job at your workshop or factory? You may ask if a Fiber Laser Cleaning Machine or an ultrasonic cleaner is better. Both ways have good and bad points. Laser cleaning does not make liquid waste. It works well on big and small surfaces. Ultrasonic cleaning is great for small parts and hidden spots. It cleans them very well. You should pick based on part size, how many parts you need to clean, and your budget.

| Factor | Laser Cleaning | Ultrasonic Cleaning |

|---|---|---|

| Cost | Costs a lot at first, but uses little electricity | You pay for cleaning solutions, water, and electricity |

| Environmental Impact | No liquid waste, good for the environment | Needs special soaps, and you must get rid of dirty water |

| Efficiency | Works well on big and small surfaces | Works well on small parts, but not for big jobs |

Tip: Pick your cleaning method based on your job, your materials, and your business goals to get the best results.

Key Takeaways

- Pick the cleaning method by looking at part size, how dirty it is, and your budget. Fiber laser cleaning works well for big surfaces. Ultrasonic cleaning is best for small and detailed parts.

- Fiber laser cleaning machines cost a lot at first. They save money over time because they are cheap to run. Ultrasonic cleaners cost less to buy but need you to keep buying cleaning solutions.

- Think about the environment. Fiber laser cleaning makes very little waste and does not use chemicals. This makes it better for the planet than ultrasonic cleaning. Ultrasonic cleaning creates dirty water and needs special soaps.

- Check how well each method cleans. Fiber laser cleaning is quick and good for tough dirt. Ultrasonic cleaning works well for tricky shapes and hidden spots but takes more time.

- Safety is important. Fiber laser cleaning needs you to wear protective gear because of the laser. Ultrasonic cleaning needs you to be careful with liquids and chemicals.

Which Method Wins?

Overall Verdict

You want the best cleaning method for your work. Fiber laser cleaning machines and ultrasonic cleaners both have good sides. Fiber laser cleaning machines clean fast and do not use chemicals. Ultrasonic cleaning can reach places you cannot see or touch. Think about your part size, how dirty it is, and your budget before you choose.

Here is a table that shows how each method is different:

| Feature | Fiber Laser Cleaning Machine | Ultrasonic Cleaning |

|---|---|---|

| Best Use | Cleans dirt from open surfaces | Cleans parts with tricky shapes |

| Cleaning Mechanism | Laser beam burns away dirt | Parts soak in a cleaning bath |

| Precision | Targets small spots | Cleans all surfaces at once |

| Impact on Parts | Gentle, does not touch the part | Bubbles can wear down parts |

| Start-Up Cost | High | Low to medium |

| Running Cost | Low | High (needs chemicals and water) |

| Waste | Dry dust and fumes | Dirty water and soap |

| Automation | Easy to use with robots | Often needs manual work |

| Safety | Needs safety gear for lasers | Needs safety gear for chemicals |

Note: Always pick the cleaning method that fits your job. Think about the part shape, how clean you want it, and your budget.

When Fiber Laser Cleaning Machine Leads

Fiber laser cleaning machines work best for big surfaces or tough dirt. The laser does not touch the part, so it does not hurt it. This method is good for delicate things that need gentle cleaning. You save time because the laser works quickly.

- You can use fiber laser cleaning machines for tire molds. The laser cleans hot molds while production keeps going. This helps you make better products and less downtime.

- The machine is easy to move. You can take it to different places.

- You do not need chemicals, so you help the environment and save money.

- The laser works well with robots, so you can clean many parts at once.

Here is another table that shows the good points:

| Advantage | Fiber Laser Cleaning Machine | Ultrasonic Cleaning |

|---|---|---|

| Speed | Very fast | Slower |

| Environmental Impact | No chemicals | Needs cleaning agents |

| Precision | Good for delicate parts | Less precise |

| Cost to Operate | Low | High |

| Efficiency | High | Medium |

Tip: Use fiber laser cleaning machines for big jobs, delicate parts, and when you want to save time and money.

When Ultrasonic Cleaning Excels

Ultrasonic cleaning is best for small parts or items with tiny spaces. The machine uses sound waves to make bubbles in the cleaning bath. These bubbles go into hidden spots and clean dirt without touching the part.

- You can clean medical tools with tricky shapes. The bubbles reach every spot and make sure the tools are very clean.

- Ultrasonic cleaning works on many materials. You can use it for metal, plastic, or glass.

- The process does not hurt delicate surfaces. You can clean items with fine details safely.

Here are some reasons to pick ultrasonic cleaning:

- You need to clean parts with holes, grooves, or tight spaces.

- You want to clean many small items at once.

- You need a gentle cleaning method for fragile parts.

Note: Ultrasonic cleaning is a good choice for small batches, complex shapes, and when you need to clean every surface.

Cleaning Principles Explained

Fiber Laser Cleaning Machine: How It Works

A Fiber Laser Cleaning Machine uses light energy to clean surfaces. It removes dirt, rust, or paint. The machine sends a strong laser beam to the dirty spot. The laser heats the dirt very fast. This heat makes the dirt break apart or turn into gas. This is called thermal ablation. Sometimes, the laser makes a small plasma cloud. The cloud helps lift the dirt away.

Here is how cleaning happens step by step:

- The laser beam shines on the dirt or rust.

- The dirt gets hot quickly from the laser.

- The heat makes the dirt swell and break off.

- The machine cleans the part without touching it.

You can change the laser’s power for different dirt or surfaces. This helps you clean well and not harm the part. Fiber Laser Cleaning Machine technology is much better now. New machines are more accurate and work faster. Some machines use AI to clean smarter. You can also get portable machines for cleaning in many places.

| Advancement Type | Description |

|---|---|

| Increased Precision | Cleans better and saves money. |

| Efficiency | Helps factories and workshops work faster. |

| Sustainability | Cleans without chemicals and is safer for nature. |

| Mobile and Portable Machines | Easy to carry for cleaning anywhere. |

| Integration of AI and Automation | AI helps make cleaning better and plan repairs. |

| Advanced Monitoring Technologies | Smart sensors help clean better and waste less. |

Tip: Fiber Laser Cleaning Machines clean fast, safely, and are good for the planet.

Ultrasonic Cleaning: How It Works

Ultrasonic cleaning uses sound waves to clean things. You put the items in a tank with cleaning liquid. The machine sends fast sound waves through the liquid. These waves make tiny bubbles in the solution. The bubbles get bigger and then pop. This is called cavitation. When bubbles pop, they make small water jets. These jets push dirt off the items.

Ultrasonic cleaning works for metals, glass, ceramics, jewelry, and electronics. You can clean things with holes, grooves, or tiny details. The cleaning power depends on the frequency you pick. Lower frequencies like 25 kHz clean thick dirt. Higher frequencies like 68 kHz or 170 kHz are gentle for delicate things.

| Mechanism | Description |

|---|---|

| Cavitation | Bubbles pop in the liquid and make jets that clean every part. |

| Effective Materials | Metals, glass, ceramics, jewelry, and electronics. |

| Cleaning Task | Suggested Equipment |

|---|---|

| Remove coarse contaminants | 25 kHz or 40 kHz units |

| Heavy-duty cleaning | 40 kHz and 45 kHz units |

| Fine cleaning sensitive surfaces | 80 kHz units |

Note: You get the best cleaning when you use the right frequency for your job.

Key Comparison Factors

Cleaning Efficiency & Speed

You want a cleaning method that is quick and does a good job. Fiber Laser Cleaning Machine works much faster than ultrasonic cleaning. The laser removes dirt fast from big surfaces. You can clean more parts in less time. Ultrasonic cleaning is better for small batches and tiny parts. It uses sound waves to reach hidden spots, but it takes longer for big jobs.

Tip: Use laser cleaning if you need speed and have lots to clean. Use ultrasonic cleaning for small, detailed items.

Cost: CAPEX vs OPEX

You should think about both the price to buy and the cost to use each machine. Fiber Laser Cleaning Machine costs more at first, but you spend less on electricity and fixing it. Ultrasonic cleaning costs less to buy, but you pay more each month for chemicals, water, and repairs.

| Category | Price Range |

|---|---|

| Entry-Level (20–150 W) | $5,000–$15,000 |

| Mid-Range Industrial (150–1,000 W) | $15,000–$50,000 |

| High-End Automated (>500 W) | $50,000–$150,000+ |

| Maintenance (Laser optics) | $500–$1,500/year |

| Maintenance (HEPA filters) | $1,000–$2,000/year |

| Annual savings vs. sandblasting/chemical | $10,000–$30,000 |

Ultrasonic cleaning machines cost about $540 each month. Over five years, you may save $90,000 with laser cleaning because it needs less fixing.

Consumables & Maintenance

You need to think about what you will use and how often you must fix your machine.

- Ultrasonic cleaning machines use water, cleaning solutions, and need regular filter changes.

- Fiber lasers need less fixing. You only replace filters and clean laser optics sometimes.

Common maintenance jobs include:

- Changing filters and fiber heads.

- Cleaning laser optics to keep the beam strong.

- Checking the cooling system to stop overheating.

Surface Damage Risk

You want to keep your parts safe. Fiber Laser Cleaning Machine does not touch the part, so it keeps delicate surfaces safe. Ultrasonic cleaning uses vibrations. These can sometimes hurt fragile materials.

| Cleaning Method | Characteristics |

|---|---|

| Fiber Laser Cleaning | Non-contact, high accuracy, good for delicate structures. |

| Ultrasonic Cleaning | Efficient, but may damage fragile materials with strong vibrations. |

Laser cleaning keeps surfaces smooth and works well for molds and optical devices.

Cleaning Range & Flexibility

You need a method that fits your part size and shape. Ultrasonic cleaning works well for complex shapes and tiny gaps. It needs a liquid bath. Fiber Laser Cleaning Machine cleans big areas and fine details. It works on tough dirt and is good for expensive parts.

| Cleaning Method | Advantages | Applicability |

|---|---|---|

| Ultrasonic Cleaning | Microscopic cleaning, gentle, non-contact, energy-efficient | Needs liquid, good for tiny gaps and inside parts |

| Laser Cleaning | Precise, controllable, non-destructive, deep cleaning | Good for complex shapes and stubborn dirt |

Laser cleaning can reach any part of an object, even tricky shapes.

Environmental & Safety Considerations

You want a safe and clean workspace. Fiber Laser Cleaning Machine makes little waste and does not use chemicals. You must wear safety gear and keep laser beams contained. Ultrasonic cleaning uses water and chemicals, which means more waste and emissions. You need to control noise and handle liquids safely.

| Aspect | Fiber Laser Cleaning | Ultrasonic Cleaning |

|---|---|---|

| Emissions | Minimal, no hazardous chemicals | Water and chemicals, more emissions |

| Waste Generation | Very little, no secondary waste | More waste from water and chemicals |

| Operator Safety | Needs laser safety protocols | Needs safety for liquids and noise |

Note: Always follow safety rules and wear protective equipment for both methods.

Pros and Cons

Fiber Laser Cleaning Machine: Pros & Cons

You might wonder why people pick a Fiber Laser Cleaning Machine. It has good points and some problems. Many users say it saves money because it needs little fixing. You can use it for many jobs and materials. The machine gives the same results every time. You can set it up to work by itself. But it costs a lot at first. You need to know how to set it up right. If you do not use it the right way, you could hurt the part. You must follow safety rules. Some jobs take longer with this machine. It needs electricity to run. If you want to use it outside, you need a portable one.

Tip: Make sure your team learns how to use the Fiber Laser Cleaning Machine. Safety and skill are very important.

Ultrasonic Cleaning: Pros & Cons

Ultrasonic cleaning works well for small parts and tricky shapes. It cleans without touching the items. You can clean fragile things if you use the right settings. It is quick and cleans every spot. You help nature because you use fewer strong chemicals. But there are some things to watch out for. The machine can be loud. You need to fix it often. If you use the wrong settings, you might hurt delicate items. The tank size means you cannot clean big things.

Note: Always read the cleaning instructions for your items. Pick the best frequency and cleaning solution for your job.

Industry Applications

Automotive & Manufacturing

Factories use fiber laser cleaning machines and ultrasonic cleaners. Fiber laser cleaning takes off oxide layers from carbon steel. It strips old coatings from stainless steel. It cleans grease from aluminum alloy parts. Ultrasonic cleaning is good for small parts and tricky shapes. You use it for delicate engine parts and complex molds.

| Material Type | Laser Cleaning Application | Ultrasonic Cleaning Application |

|---|---|---|

| Carbon Steel | Removes oxide layers to help welding | Cleans small parts |

| Stainless Steel | Strips old coatings for better sticking | Cleans tricky components |

| Aluminum Alloy | Removes grease without hurting the part | Cleans delicate engine parts |

Tip: Pick fiber laser cleaning for big surfaces and tough dirt. Use ultrasonic cleaning for small, detailed parts.

Electronics & Precision Parts

Electronics and precision parts need gentle cleaning. Ultrasonic cleaning reaches tiny spaces and blind holes. You use it for circuit boards, sensors, and micro-parts. Fiber laser cleaning takes away small bits of dirt. This helps keep instruments working well.

| Application | Description |

|---|---|

| Ultrasonic Cleaning Systems | Cleans parts with blind holes and tricky shapes. |

| Laser Cleaning Technology | Removes tiny dirt, making instruments last longer. |

Restoration & Conservation

You use special cleaning tools to protect history. Fiber laser cleaning takes off dirt and oxidation from old things and building materials. You use it for restoring, treating surfaces, and removing paint. It does not need water or chemicals. This helps you follow strict rules for the environment.

- Takes off dirt without hurting surfaces

- Easy to carry and use

- Good for nature, no bad waste

- Saves money, costs less to run

- Lets you clean only what you want

Note: Change laser settings to clean certain dirt and keep fragile things safe.

Aerospace & Medical Devices

Aerospace and medical devices need very clean parts. Fiber laser cleaning makes aircraft and medical parts better and safer. Ultrasonic cleaning uses sound waves to clean tricky parts like catheters and engine pieces. Both ways help you keep instruments accurate and lasting longer.

| Cleaning Technology | Cleaning Mechanism | Industry Application |

|---|---|---|

| Fiber Laser Cleaning | Removes dirt with strong vibrations | Makes aerospace and medical parts better |

| Ultrasonic Cleaning | Moves cleaning liquid with fast sound waves | Cleans tricky parts in medical and aerospace jobs |

| Laser Cleaning Technology | Takes away tiny dirt, helping tools last longer | Makes measurements better and tools last longer |

Tip: Pick the cleaning method that fits your industry’s safety, accuracy, and reliability needs.

Choosing the Right Method

Key Questions to Ask

You want to pick the best cleaning method for your job. Start by asking yourself these questions:

- What type of material do you need to clean?

- How dirty are your parts?

- Are the parts big or small?

- Do you need to clean many items at once or just a few?

- What is your budget for buying and running the machine?

- Do you need a gentle cleaning process for fragile items?

- Is it important to avoid chemicals or liquid waste?

Tip: Write down your answers. This helps you see which method fits your needs.

Matching Method to Application

You can match the cleaning method to your job by looking at your answers. Use the table below to help you decide:

| Situation | Best Method |

|---|---|

| Large, flat surfaces | Fiber Laser Cleaning |

| Small parts with tiny spaces | Ultrasonic Cleaning |

| Need fast cleaning | Fiber Laser Cleaning |

| Fragile or detailed items | Ultrasonic Cleaning |

| Want to avoid chemicals | Fiber Laser Cleaning |

| Cleaning many small items | Ultrasonic Cleaning |

If you clean big batches or want to save time, fiber laser cleaning works well. If you clean small, tricky parts, ultrasonic cleaning is better.

Budget & Operational Considerations

You need to think about costs and how you will use the machine. Fiber laser cleaning costs more to buy, but you spend less on running it. Ultrasonic cleaning costs less at first, but you pay for water and cleaning solutions every month.

Checklist for Choosing:

- Check your budget for buying and running the machine.

- Look at your part size and shape.

- Think about how many parts you clean each day.

- Decide if you want to avoid chemicals.

- Choose the method that matches your answers.

Note: If you still feel unsure, talk to a cleaning expert. They can help you pick the right machine for your business.

You have learned that fiber laser and ultrasonic cleaning each offer unique strengths. Your best choice depends on your part size, cleaning needs, and business goals. Use this checklist to decide:

- Know your material and dirt type.

- Check your budget.

- Think about batch size and speed.

If you feel unsure, talk to a cleaning expert. You can make a smart decision and improve your cleaning results.

FAQ

What materials can you clean with a fiber laser cleaning machine?

You can clean metals like steel, aluminum, and copper. It also works on stone, concrete, and some plastics. Always check if your material is safe for laser energy before you start.

Is ultrasonic cleaning safe for electronics?

Yes, you can use ultrasonic cleaning for electronics. Take out batteries before cleaning. Dry the parts well after you finish. Pick the right frequency and cleaning solution to keep delicate pieces safe.

How much maintenance do these machines need?

Fiber laser cleaning machines need filter changes and lens cleaning. Ultrasonic cleaners need tank cleaning and solution changes often. Both machines last longer if you follow the maintenance schedule.

Can you use these methods for painted surfaces?

Fiber laser cleaning can take off paint without hurting the base. Ultrasonic cleaning is best for dirt or grease, not paint. Try cleaning a small spot first.

Which method is better for cleaning small, detailed parts?

Ultrasonic cleaning is best for small, detailed parts. Sound waves reach tiny spaces and clean every surface. Fiber laser cleaning works better for big or flat surfaces.

See also

Analysis of reasons for cleaning and damage of laser lenses

Laser Cleaning Made Simple with Smart Control Tech