Industrial handheld laser welding machine

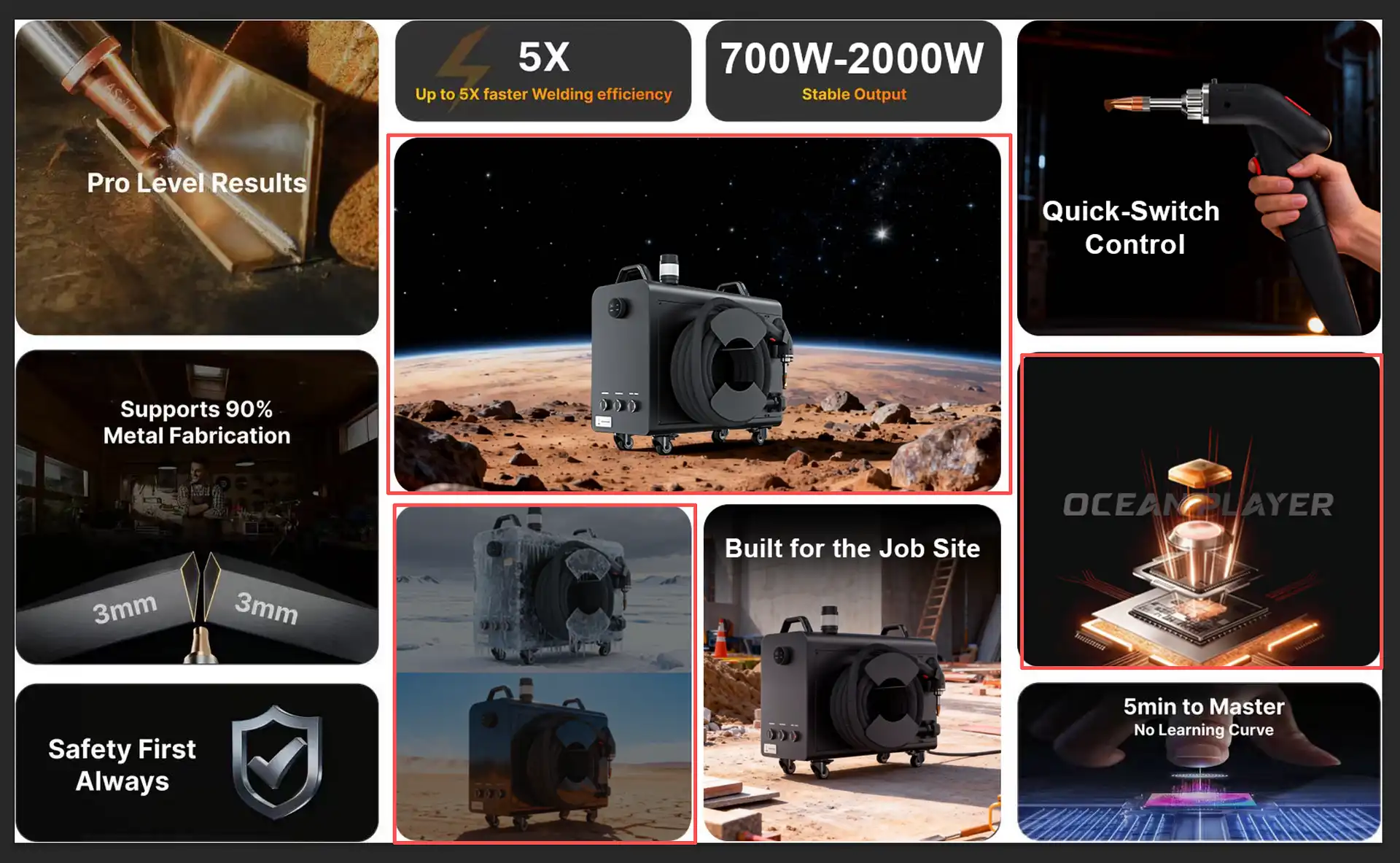

Stop relying on expensive skilled labor. Our intelligent handheld laser welder makes welding 4X faster and easier than TIG, with zero deformation.

Deep Penetration

Full penetration up to 8mm for stainless and carbon steel.

Flawless Finish

Creates smooth, uniform weld seams instantly

Certified Safety

Equipped with nozzle contact sensors and dual-trigger locks

4X Faster Speed

120mm/s welding speed for instant efficiency

5-Minute Training

Built-in process library. No welding license required.

2-in-1 Versatility

Seamlessly switch between Welding and Cutting.

Comparison of welding methods

Compare the results instantly: Traditional methods leave scars and warping, while Ocean Player laser welding creates flawless, high-strength joints with zero post-processing.

Traditional Welding (TIG/MIG)

Ocean Player laser welding

Find a suitable laser welding machine for your job

Compare the results instantly: Traditional methods leave scars and warping, while Ocean Player laser welding creates flawless, high-strength joints with zero post-processing.

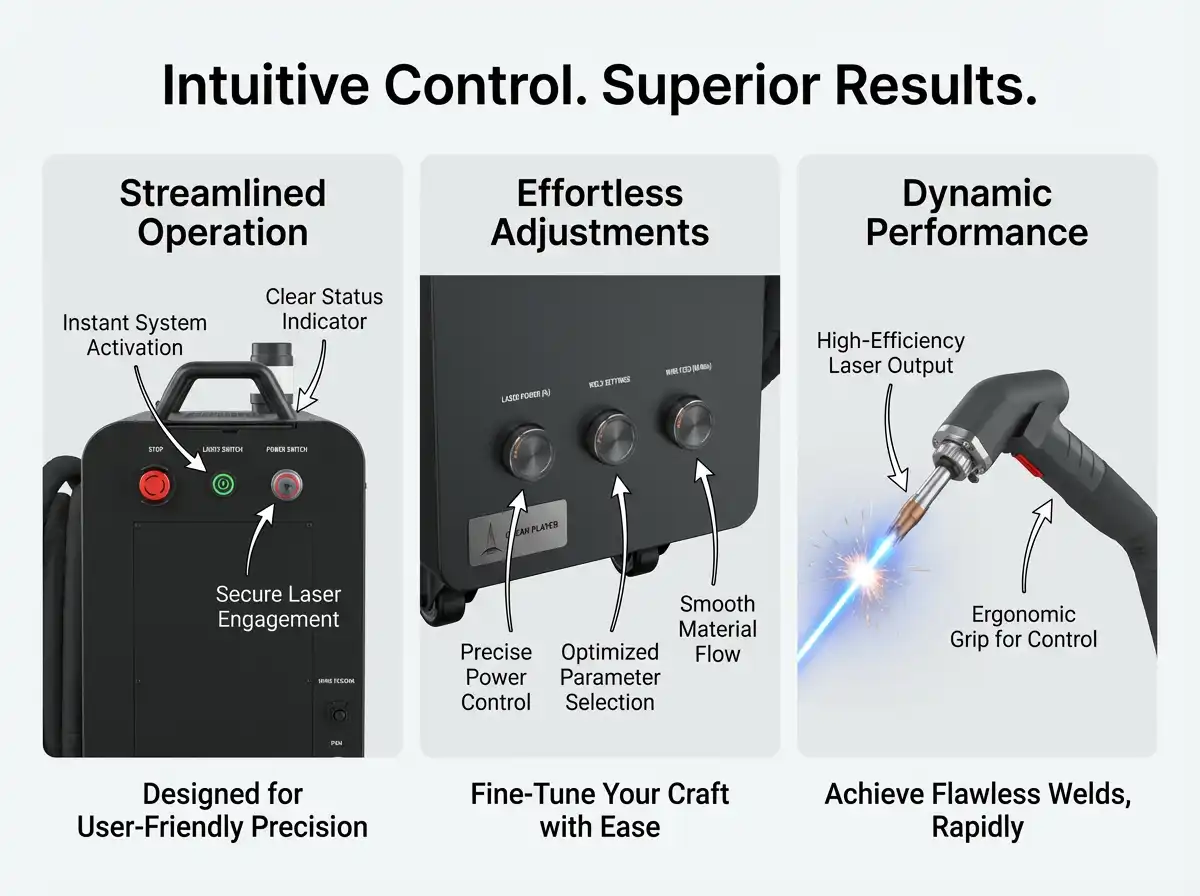

Core Function Display

Multi-Material Welding Capability

Don’t let material limitations slow you down. Ocean Player laser welders provide stable, high-quality joints for:

✅ Stainless Steel (Shiny & Smooth)

✅ Carbon Steel (Deep Penetration)

✅ Aluminum & Brass (High Reflectivity Handled)

| Laser Power | Carbon Steel | Stainless Steel | Aluminum | Brass/Copper |

|---|---|---|---|---|

| 700W | ≤ 2.0 mm | ≤ 2.0 mm | ≤ 1.0 mm | Not Recommended |

| 1000W | ≤ 3.0 mm | ≤ 3.0 mm | ≤ 2.0 mm | ≤ 1.0 mm |

| 1500W | ≤ 4.5 mm | ≤ 4.5 mm | ≤ 3.0 mm | ≤ 1.5 mm |

| 2000W | ≤ 6.0 mm | ≤ 6.0 mm | ≤ 4.0 mm | ≤ 2.0 mm |

| 3000W | ≤ 8.0 mm | ≤ 8.0 mm | ≤ 6.0 mm | ≤ 3.0 mm |

Your trusted laser welding machine manufacturer

Since 2015, Ocean Player has empowered metal fabricators worldwide from our 5,000m² facility in Shenzhen. We specialize in producing industrial-grade handheld welders designed to replace traditional TIG/MIG methods, ensuring you get factory-direct quality and solving your skilled labor shortages.

🏭 5,000m² Production Base

👨🔧 10+ Years Industry Expertise

🌍 50+ Countries Exported

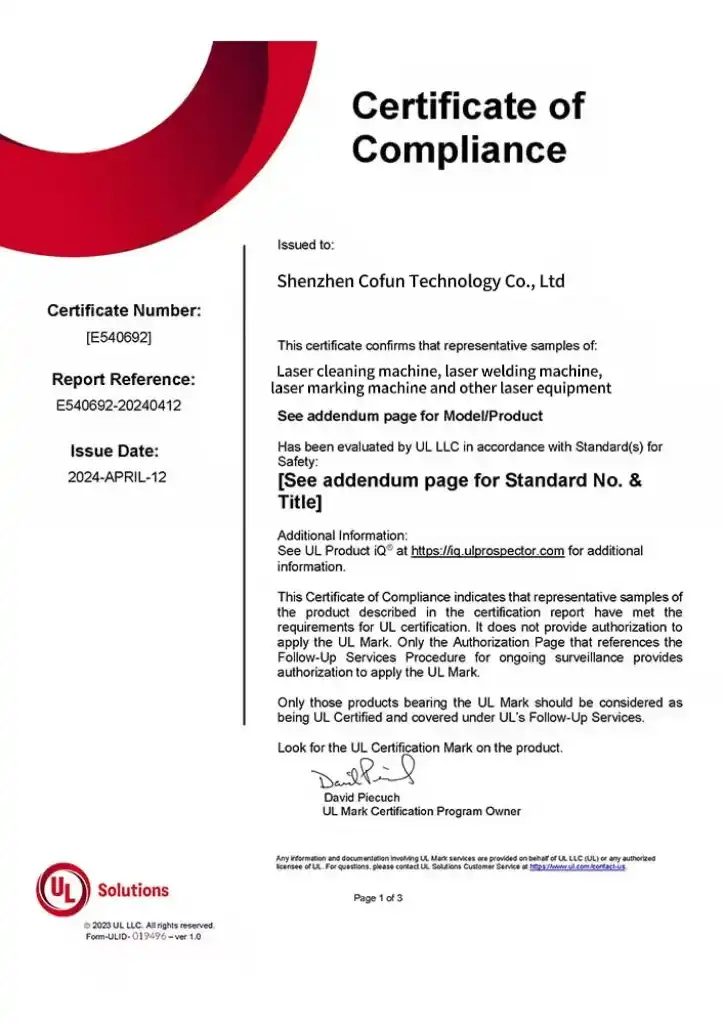

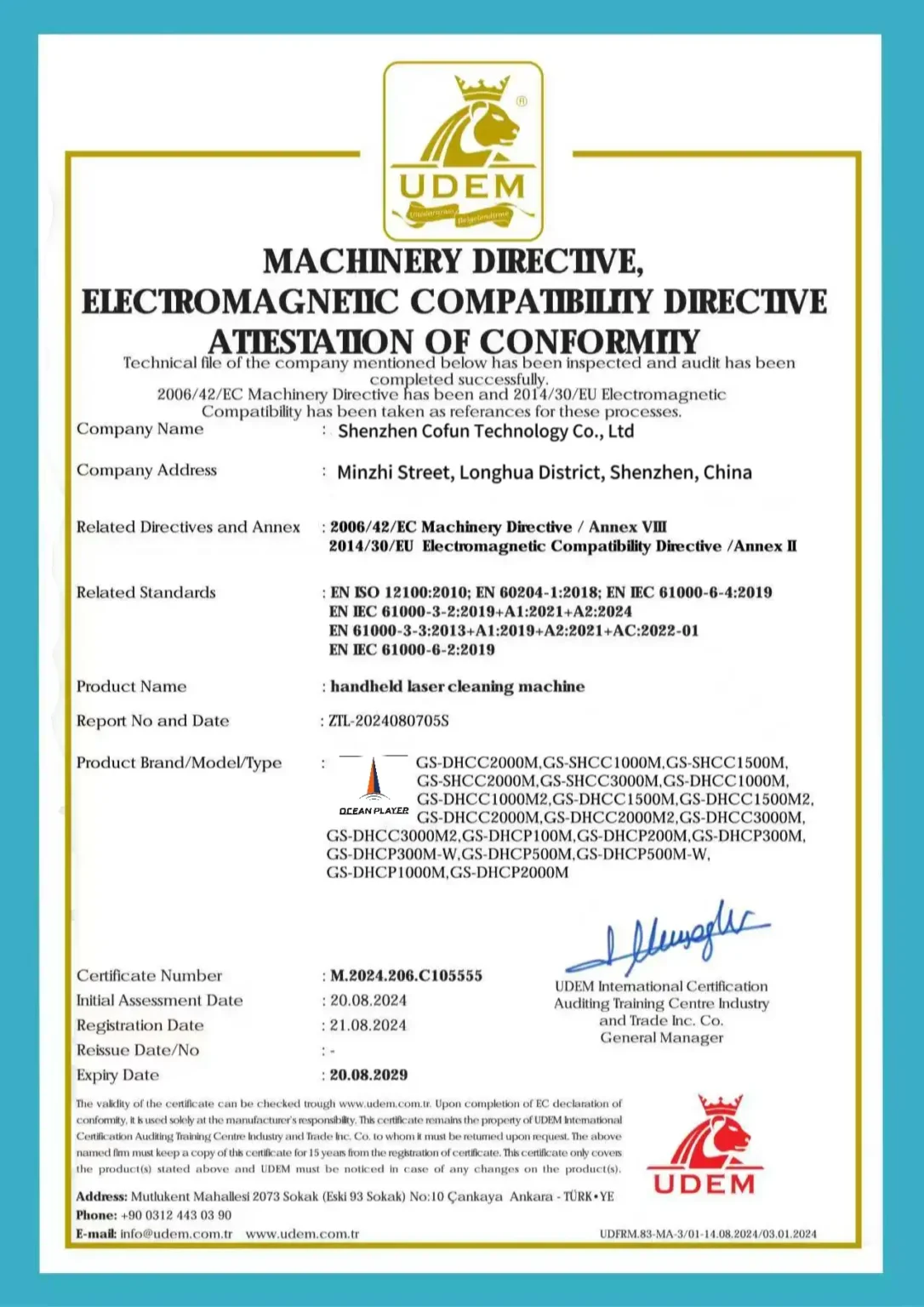

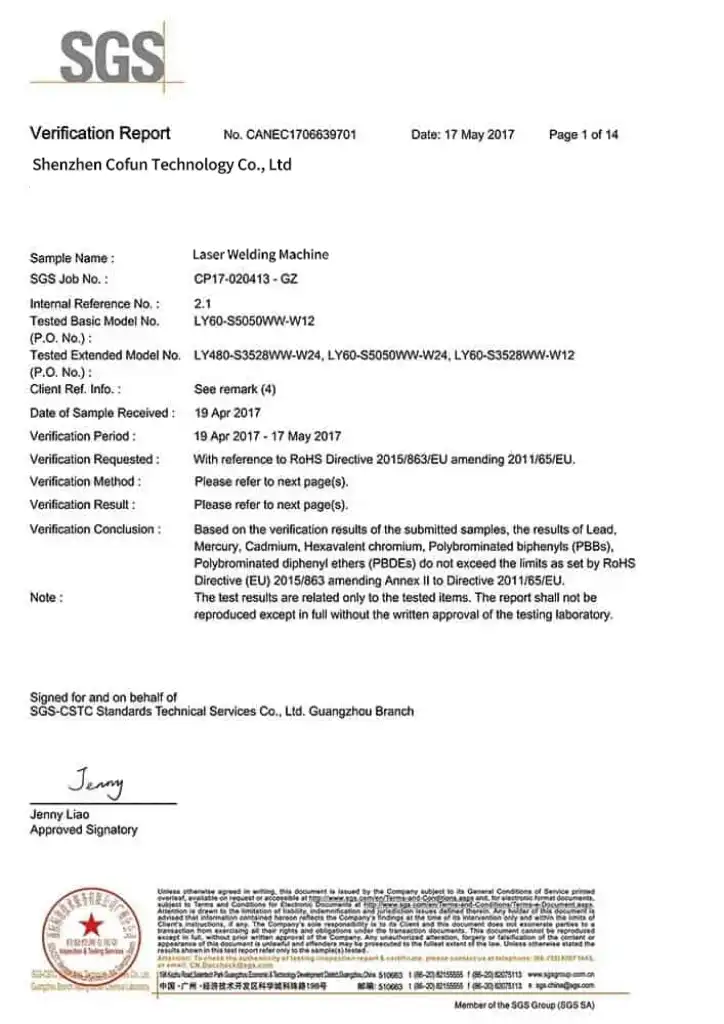

Certification

We have passed TUV’s CE certification, ROHS certification, FDA certification, ETL CSA certification, and comply with European and American standards.

Trusted by Metal Fabricators Worldwide

See how Ocean Player handheld laser welders help businesses solve labor shortages and boost production speed by 400%.

FAQ

Do I need a professional welder to operate this machine?

No, absolutely not. This is the biggest advantage of laser welding. The machine has a built-in process library (presets). An ordinary worker without any welding experience can master the operation within 10-30 minutes. It solves your difficulty in hiring skilled welders.

Is the wire feeder included? What kind of wire should I use?

Yes, the Automatic Wire Feeder is included for FREE. It supports standard welding wires (Stainless Steel, Carbon Steel, Aluminum) with diameters of 0.8mm / 1.0mm / 1.2mm / 1.6mm. You can easily buy these wires locally.

What consumables do I need to buy?

The running cost is very low. You only need:

Shielding Gas: Argon or Nitrogen (to prevent oxidation).

Copper Nozzles: Replace every 1-2 months depending on usage.

Protective Lens: Replace when dirty (usually 1-2 weeks). We include a starter pack of nozzles and lenses with the machine.

Can it weld Aluminum and Galvanized sheets?

Yes, perfectly.

For Aluminum: The laser beam controls heat input precisely, preventing burn-through and deformation even on thin sheets.

For Galvanized Steel: Our specialized mode minimizes zinc splatter, ensuring a strong and clean joint.

Is handheld laser welding safe?

Yes, we have triple safety protection.

Safety Clip: The laser ONLY fires when the nozzle touches the metal and the ground clamp is connected.

Protective Glasses: We provide certified laser safety glasses for the operator.

Emergency Stop: A physical button to cut power instantly.

What is the warranty policy?

We offer a 2-Year Warranty for the Laser Source and a 1-Year Warranty for the whole machine. If any part fails, our engineers will diagnose it via video call and ship the replacement part by air immediately (DHL/FedEx).