When you pick laser cleaning or sandblasting, you want a safe and good way to clean. Laser cleaning is best for gentle surfaces. It makes almost no waste. Sandblasting is good for hard dirt but needs special safety equipment. You can see the main differences in the table below:

| Criteria | Laser Cleaning | Sandblasting |

|---|---|---|

| Safety | Safer for the environment and needs few safety steps | Can be risky and needs special handling |

| Waste Generation | Makes very little or no waste | Makes a lot of waste |

| Speed | Faster for small spots | Better for big areas |

| Suitability | Great for gentle materials | Works well for tough dirt |

You should choose the cleaning method that fits your materials and needs for the best results.

Key Takeaways

- Laser cleaning is safer and makes almost no waste. This helps the environment. Sandblasting works well for thick rust and paint. But it needs special safety gear because of dust. Use laser cleaning for delicate surfaces and careful jobs. It keeps the material safe. Sandblasting is good for big areas and tough dirt. But it can hurt soft materials. Think about your budget. Laser cleaning costs more at first. But it saves money on waste later. Both methods have special uses. Laser cleaning is best for aerospace and electronics. Sandblasting is better for building and cars. Always put safety first. Laser cleaning needs little gear. Sandblasting needs full safety equipment. Look at your project needs. Pick the best cleaning method for your materials and goals.

Quick Comparison Table

You might wonder which cleaning method is better for your work. The table below helps you compare laser cleaning and sandblasting. It shows how they differ in safety, waste, speed, cost, and how well they clean.

| Feature | Laser Cleaning | Sandblasting |

|---|---|---|

| Safety | Only eye protection needed. Safer for workers. | Dust is dangerous. You need full safety gear. |

| Waste Output | Almost no waste. No leftover cleaning stuff. | Makes lots of solid waste. Needs careful cleanup. |

| Speed | Fast on big, flat areas (10-20 sq m/hr). | Slower for large spaces. Faster for small parts. |

| Cost | Costs more to buy. Cheaper to run later. | Cheaper to start. You keep paying for supplies. |

| Effectiveness | Very exact. Good for light rust and coatings. | Strong. Takes off thick rust and heavy coatings. |

Pros and Cons

Think about the good and bad sides before you pick. Here are the main pros and cons for each way to clean:

Laser Cleaning

- 👍 Good for the environment. You do not have leftover waste.

- 👍 Exact and gentle. You can clean soft surfaces safely.

- 👍 Needs little fixing. You save time and money.

- 👎 Costs a lot at first. Machines are expensive.

- 👎 You need to learn how to use it.

- 👎 Not great for thick rust or paint.

Sandblasting

- 👍 Takes off thick rust, paint, and coatings fast.

- 👍 Works on many shapes and sizes. Big or small parts.

- 👍 Saves money for one-time jobs. Cheaper at the start.

- 👎 Can be unsafe. Dust can hurt your lungs. You need full gear.

- 👎 Makes lots of waste. You must clean up used stuff.

- 👎 You keep paying for supplies and fixing equipment.

Safety Tip: Sandblasting makes silica dust. This dust can cause bad lung sickness. Over 2 million workers in the U.S. face this danger. Laser cleaning only needs eye protection and makes less harmful waste.

Best Uses

Pick the cleaning way that fits your job for the best results. Here are the top things each method is good for:

| Cleaning Method | Best Use Cases | Industries |

|---|---|---|

| Laser Cleaning | Thin dirt or rust, soft metals, sensitive surfaces | Aerospace, electronics, medical tools |

| Sandblasting | Thick rust, heavy coatings, large surfaces, texturing | Shipyards, construction, auto shops |

- Use laser cleaning for airplane parts, circuit boards, and medical tools. It is gentle and gives a clean finish.

- Pick sandblasting for ship parts, steel beams, and car frames. It removes tough dirt quickly and gets surfaces ready for paint.

Effectiveness

On Different Materials

Metals

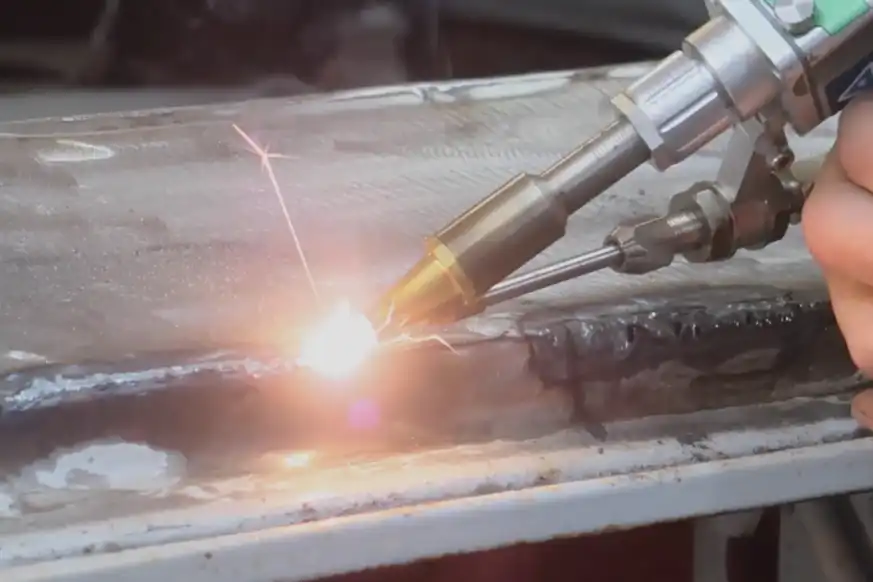

Many industries use metal parts. Laser cleaning is very exact. It takes off rust and dirt without hurting the metal. It turns the rust into gas. Sandblasting is strong. It removes thick rust and old paint. But if you use too much force, it can harm the metal.

| Method | Effectiveness on Metals |

|---|---|

| Laser Cleaning | Removes rust by vaporizing corrosion without damage |

| Sandblasting | Highly effective for heavy rust and corrosion removal |

Plastics and Composites

Plastics and composites are soft. They need gentle cleaning. Laser cleaning can take off paint and dirt. It does not hurt the surface. Sandblasting is fast at removing paint. But it can scratch or break soft parts. Use laser cleaning for fragile pieces. Use sandblasting for strong, tough jobs.

| Method | Effectiveness on Plastics | Effectiveness on Composites |

|---|---|---|

| Laser Cleaning | Can remove paint without affecting substrate | Moderate |

| Sandblasting | Strips multiple layers of paint | High |

You can look at the chart below to see how both ways work on different materials:

| Surface Type | Laser Cleaning Compatibility | Sandblasting Compatibility |

|---|---|---|

| Metals | High | Moderate to High |

| Stone & Masonry | High | Low |

| Ceramics & Glass | Moderate | Low |

| Polymers & Composites | Moderate | High |

| Wood & Organics | High | Low |

Contaminant Removal

Rust and Oxides

Rust and oxides make metal weak. Laser cleaning uses a strong light to turn rust into gas. It works well on metals, ceramics, and stones. Sandblasting is quick for thick rust. But it makes dust. You may need to clean again after.

- Laser cleaning takes off rust and oxides from metals, ceramics, and stones.

- Sandblasting works on big areas but makes dust that can stick again.

Paint and Coatings

Paint and coatings protect things. Sometimes you need to take them off. Laser cleaning lets you control how much you remove. It does not hurt the base. Sandblasting takes off many layers fast. It is best for hard coatings on strong surfaces.

- Laser cleaning takes off paint and coatings from metals and plastics without damage.

- Sandblasting removes many layers of paint and coatings, good for big or hard jobs.

Oil and Grease

Oil and grease make surfaces slippery. Laser cleaning can take off oil and grease from metals and other things. Sandblasting can also do this, but it is less exact. You may have to clean up dust and bits after.

- Laser cleaning uses focused light to remove oil and grease from metal.

- Sandblasting is fast and cheap but may need more cleaning after.

| Method | Contaminant Removal Efficiency | Surface Damage | Waste Volume Reduction |

|---|---|---|---|

| Laser Cleaning | 99.9998% (two passes) | Negligible | 25% of removed material |

| Sandblasting | Lower efficiency | Higher damage | Greater waste volume |

Surface Finish

You want your surface to look nice and stay strong. Laser cleaning keeps the surface looking new. It does not scratch or crack the material. Sandblasting changes how the surface feels. It can make tiny cracks and take away some of the material. Use laser cleaning for soft or delicate things. Use sandblasting when you need a rough surface.

| Method | Surface Finish Quality | Effects on Substrate Integrity |

|---|---|---|

| Laser Cleaning | Preserves original surface finish, ideal for delicate surfaces | Non-contact, non-abrasive, does not remove base material |

| Sandblasting | Alters surface profile, can introduce microcracks and surface damage | Mechanical abrasive, can remove base material |

Tip: If you want to keep your material looking and feeling the same, pick laser cleaning. For tough jobs where you do not care about the look, sandblasting is a good choice.

Laser Cleaning: Safety and Environment

Worker Safety

When you use laser cleaning, you work in a safer environment than with sandblasting. You do not need to wear heavy suits or full-face masks. Most of the time, you only need eye protection. Still, you must follow some important safety steps to keep everyone safe:

- A Laser Safety Officer (LSO) must watch over the work area and make sure you follow all safety rules.

- You must set up a controlled area to keep laser beams from reaching other people.

- The LSO will train you and your team on how to use the equipment safely.

- You need to use the right protective gear, like special glasses.

- The LSO will check safety steps often to make sure nothing is missed.

- You should get regular health checks, including eye exams.

- You cannot use Class IV lasers at public events.

- You should avoid letting the laser beam touch your skin for a long time.

Sandblasting has more risks. Breathing in dust can cause lung diseases like silicosis. Loud noise from blasting can hurt your hearing. Flying bits of material can injure your eyes and skin. You must wear full safety gear, including masks, gloves, and ear protection.

Tip: Laser cleaning keeps you safer and makes your job easier. You do not have to deal with as much dust or noise.

Waste and Pollution

Laser cleaning creates very little waste. You do not use sand, grit, or chemicals. This means you do not have to clean up piles of used material. You save time and money because you do not need to handle or throw away much waste. Sandblasting, on the other hand, leaves behind a lot of used abrasive material. This waste can include harmful substances that need special disposal.

When you use laser cleaning, you help the environment. You lower the amount of waste your job creates. You also reduce the risk of spreading dangerous dust or chemicals.

Regulatory Considerations

You must follow certain rules when you use laser cleaning or sandblasting. In the United States, the ANSI Standard Z136.1 tells you how to use lasers safely. In Europe, EN 60825-1 and IEC-60825 give similar rules. These standards help you set up safe work areas and train your team.

| Region | Standard | Description |

|---|---|---|

| United States | ANSI Z136.1 | Rules for safe use of lasers in the U.S. |

| Europe | EN 60825-1 | European rules for laser safety, similar to ANSI Z136.1 |

| Europe | IEC-60825 | Guidance for finding and controlling laser hazards in Europe |

You may also need to follow local rules. For example, in Germany, BGV B2 covers laser beams. In the U.S., the FDA’s CDRH requires you to label laser equipment and follow safety steps. Sandblasting has its own rules. OSHA requires you to have a plan for dust, wear protective clothing, and get medical checks. You must also make sure you have good ventilation and a way to get rid of waste safely.

Note: Laser cleaning has fewer rules about waste and pollution. Sandblasting needs more steps to protect workers and the environment.

Cost and Efficiency

Equipment and Setup

When you choose a cleaning method, you need to think about the cost of equipment and setup. Laser cleaning and sandblasting both require special machines. You must plan for the money you spend at the start. The table below shows the average initial investment for small and medium businesses:

| Equipment Type | Average Initial Investment |

|---|---|

| Sandblasting Equipment | $25,000–$500,000 |

| Laser Cleaning Equipment | $35,000–$500,000 |

Laser cleaning machines often cost more at the beginning. You pay for advanced technology and safety features. Sandblasting equipment can be cheaper, but prices go up if you need large systems or extra safety gear. You also need to set up a safe workspace for both methods. Laser cleaning needs a controlled area with safety signs and barriers. Sandblasting requires strong ventilation and dust control systems.

Tip: If you want to save money at the start, sandblasting may look better. Laser cleaning costs more, but it gives you cleaner results and safer working conditions.

Operating Costs

You must think about the money you spend to keep your cleaning system running. Laser cleaning has higher ongoing costs. You need to pay for regular maintenance and replace laser optics. The machines use a lot of electricity. These costs add up over time. Sandblasting costs less to operate. You buy abrasive materials like sand or grit. You also pay for fixing worn-out parts. The main expenses come from buying new media and keeping the equipment in good shape.

Laser cleaning needs more care and uses more power. Sandblasting uses up materials quickly, so you keep buying supplies. Both methods need you to check and fix machines often. You spend more on laser cleaning for repairs and energy. Sandblasting costs less each month, but you must handle and dispose of waste.

Note: Laser cleaning saves you money on waste disposal. Sandblasting makes more waste, which can cost extra to remove.

Speed and Productivity

You want to finish your cleaning jobs fast and get good results. Laser cleaning works quickly on small spots and delicate surfaces. You can clean up to 20 square meters per hour on flat areas. The process is exact and does not harm the material. Sandblasting is better for big surfaces and tough dirt. You can clean large parts faster, but you need to stop and clean up waste.

Laser cleaning lets you work without stopping for cleanup. You spend less time setting up and moving equipment. Sandblasting needs more breaks to change media and clear dust. You may finish big jobs faster with sandblasting, but you spend more time on safety and cleanup.

- Laser cleaning gives you steady results and less downtime.

- Sandblasting helps you tackle heavy-duty jobs and large surfaces.

If you want speed and a clean workspace, laser cleaning is a smart choice. For rough jobs and thick coatings, sandblasting gets the work done quickly.

Application Suitability

Industrial Applications

Manufacturing

Both laser cleaning and sandblasting are used in factories. Each one is good for different jobs. Laser cleaning is best when you need to be careful. It takes off light rust or coatings from machine parts. The surface stays safe and smooth. Sandblasting works better for tough jobs. It strips thick paint or cleans big metal frames.

Some things help you pick the right method:

- Material Sensitivity: Use laser cleaning for soft surfaces. Sandblasting is for strong materials.

- Contaminant Type: Laser cleaning removes light dirt. Sandblasting takes off heavy rust or thick paint.

- Precision Requirements: Laser cleaning is exact. Sandblasting cleans large areas.

- Environmental and Safety Concerns: Laser cleaning makes less waste and is safer.

- Budget and Time Constraints: Sandblasting costs less at first and is fast. Laser cleaning saves money later.

Automotive

Car makers want to clean parts without damage. Laser cleaning is used to remove rust, paint, or grease from car parts. It keeps metal strong and smooth. Sandblasting is still used for big jobs. It cleans car frames or gets surfaces ready for paint. You must wear full safety gear with sandblasting.

Aerospace

Airplane companies need very exact cleaning. Laser cleaning is the best choice. It takes off coatings and dirt from airplane parts. The shape and strength do not change. Sandblasting is not used much. It can hurt sensitive parts.

Here is a table showing which industries like each method:

| Industry | Preferred Method |

|---|---|

| Aerospace | Laser Cleaning |

| Automotive | Laser Cleaning |

| Manufacturing | Laser Cleaning |

| Heritage Restoration | Laser Cleaning |

Laser cleaning is picked when safety and precision are most important.

Restoration and Conservation

You may work with old buildings or statues. Laser cleaning gives you control and accuracy. It removes rust or dirt but does not harm the original material. This is great for delicate historical items. Sandblasting can scratch or change the surface. Experts do not use it for valuable artifacts.

Tip: Pick laser cleaning for restoration jobs. It protects the look and shape of old things.

DIY and Small Business

If you have a small shop or do home projects, you have special needs. Laser cleaning is very exact and keeps your space clean. It is safe and good for the planet. But the machines cost a lot. Sandblasting is cheaper to start and works for many jobs. It makes dust and needs more cleaning.

| Benefit/Challenge | Laser Cleaning | Sandblasting |

|---|---|---|

| Precision | Very exact, few mistakes | Less exact, can cause damage |

| Environmental Impact | Good for the planet, no chemicals | Makes dust and waste |

| Health Risks | Safer for health | Needs safety gear |

| Cost | Costs more at first | Cheaper to start |

| Flexibility | Less flexible, often custom-made | More flexible, fits many jobs |

| Surface Suitability | Good for soft surfaces | Can hurt soft surfaces |

| Cleanup | Needs little cleaning after | Needs lots of cleaning after |

Laser cleaning may not work for every small business. The price is high and setups are custom. Sandblasting can be too rough for soft things. It also means more cleaning and finishing work. Always think about your needs, budget, and what you want to clean.

Decision Guide

Choosing the Right Method

You want to pick the cleaning method that fits your job. Start by looking at your budget. Laser cleaning costs more at first, but you save money on waste and safety gear. Sandblasting is cheaper for big jobs, but you keep buying supplies.

Think about what you need to clean. If you work with soft metals or delicate surfaces, laser cleaning gives you control and keeps the material safe. Sandblasting works better for thick rust or paint on strong surfaces. You get fast results on large areas.

Check your project specifications. You need to know the type of material, the kind of dirt, and the size of the area. Laser cleaning is best for small, precise jobs. Sandblasting is good for big, tough tasks.

Industry standards matter. If you work in aerospace or electronics, you must follow strict rules. Laser cleaning meets these standards because it is exact and safe. Sandblasting may not fit the rules for sensitive parts.

You should also think about other factors. Site access can change your choice. If you work in a small space, laser cleaning is easier to set up. Sandblasting needs more room and strong ventilation. The sensitivity of the surface, the amount of waste, and the noise level all play a part.

Here is a quick checklist to help you decide:

- What is your budget for equipment and supplies?

- What type of material do you need to clean?

- How big is the area?

- Do you need to follow industry standards?

- Is the surface sensitive or delicate?

- How much waste can you handle?

- How much noise and dust is allowed?

Tip: If you want precision and safety, choose laser cleaning. For heavy-duty jobs and large surfaces, sandblasting is often the better choice.

Common Mistakes

You can avoid problems by knowing the common mistakes people make when choosing a cleaning method.

- Ignoring material sensitivity: Some users pick sandblasting for soft surfaces. This can cause scratches or damage. Always check if the material can handle abrasive cleaning.

- Overlooking waste management: Sandblasting creates a lot of waste. If you do not plan for cleanup, you may face extra costs and safety risks.

- Skipping safety steps: You must use the right safety gear. Sandblasting needs masks and suits. Laser cleaning needs eye protection and a controlled area.

- Not checking industry standards: Some jobs have strict rules. If you ignore these, you may fail inspections or damage parts.

- Choosing based only on cost: The cheapest method is not always the best. Think about long-term costs, safety, and results.

Note: You get better results when you match the cleaning method to your needs. Take time to review your project before you start.

You have two good ways to clean things. Each way is better for different jobs.

- Laser cleaning is best for gentle work. It is good for the planet and very exact. You get a smooth look and do not need much fixing.

- Sandblasting works well on big areas. It is quick and does not cost a lot. You might need to polish the surface after you finish.

| Method | Advantages | Disadvantages |

|---|---|---|

| Laser Cleaning | Does not scratch, good for nature, exact | Costs more at first |

| Sandblasting | Quick, good for large jobs | Can hurt material, not as exact |

Think about your job and what is most important. For tricky jobs, ask someone who knows a lot. Pick the way that gives you the best results.

FAQ

What safety gear do you need for laser cleaning?

You only need special safety glasses for laser cleaning. You do not need heavy suits or masks. Always follow safety rules and keep the work area controlled. A Laser Safety Officer should train you and check your equipment.

Can you use sandblasting on soft materials?

Sandblasting works best on hard surfaces. You should avoid using it on soft materials like plastics or wood. It can scratch or damage these surfaces. Laser cleaning is safer for delicate items.

Does laser cleaning remove thick rust or paint?

Laser cleaning works well for light rust and thin coatings. You may need several passes for thicker layers. Sandblasting removes heavy rust and paint faster. Choose the method based on the thickness of the material you want to clean.

Which method costs less over time?

Sandblasting costs less at first. You pay more for supplies and waste disposal later. Laser cleaning costs more to buy, but you save money on waste and maintenance. Over time, laser cleaning can be more cost-effective for frequent use.

Is laser cleaning safe for the environment?

Laser cleaning creates almost no waste. You do not use chemicals or abrasive materials. This method helps protect the environment. You lower pollution and reduce cleanup time.

Can you use these methods for home projects?

You can use sandblasting for many DIY jobs. It is cheaper and easier to set up. Laser cleaning works well for small, precise tasks, but the equipment costs more. You should choose based on your budget and project needs.

How do you choose between laser cleaning and sandblasting?

Check your material, job size, and budget. Use laser cleaning for delicate surfaces and precise work. Pick sandblasting for tough dirt and large areas. Always think about safety, waste, and long-term costs before you decide.

See also

What Are the Common Hazards When Using Laser Cleaning

Laser Cleaning Machine Process Explained in 5 Simple Steps