You may ask which types of paint work best with laser removal. Not all types of paint react the same to this method. Some types of paint come off easily, while others are harder to remove or can damage the surface below. Always check what type of paint is on the object first. Also, find out what material is under the paint. This helps you avoid bad results and keeps your project safe.

Key Takeaways

- Find out what kind of paint you have before using laser removal. Different paints act in different ways with lasers.

- Laser removal works best on acrylic, epoxy, polyurethane, enamel, and latex paints. Always try it on a small spot first.

- Metals like steel, aluminum, and copper are great for laser paint removal. You can also clean non-metals like wood and glass if you are careful.

- Change the laser settings for the paint type and surface condition. This helps remove paint well without causing damage.

- Laser paint removal is good for the environment. It makes less waste and does not use harmful chemicals.

- Wear the right safety gear, like laser goggles and flame-resistant clothes, to keep safe during the process.

- Think about hiring experts for hard jobs. They know how to do laser removal safely and well.

- Know that laser equipment can cost a lot at first. But it can save money over time.

Types of Paint Removable by Laser

If you want to use laser removal, you should know which paints work best. Some paints come off easily with a laser, but others do not. This part tells you which paints and coatings you can take off with a laser and which ones might be hard to remove.

Common Paint Types

Laser removal works on many paints you see often. Here are some main types you can remove:

Acrylic

Acrylic paint dries fast and does not wash away with water. You can find it on metal, plastic, and wood. Laser removal can break down acrylic paint without hurting what is under it. This makes acrylic easy to take off with a laser.

Epoxy

Epoxy paint makes a strong, hard layer. You see it on floors, machines, and cars. Lasers can take off epoxy by breaking the paint’s hold on the surface. You get a clean look without using strong chemicals.

Polyurethane

Polyurethane paint keeps surfaces safe from damage and chemicals. It is used on machines and cars. Laser removal works well because the laser breaks down the tough paint.

Enamel

Enamel paint looks shiny and smooth. You see it on appliances, metal, and signs. Lasers can take off enamel paint, but you may need to change the laser for thick paint.

Latex

Latex paint is water-based and easy to put on. You see it on walls, ceilings, and furniture. Laser removal can take off latex paint fast, especially if it is a thin layer.

Tip: Laser cleaning, also called laser coating removal, uses a laser beam to take off coatings from many things. This way does not hurt what is under the paint.

Coatings and Specialty Layers

Some special coatings also come off with a laser. These include:

Powder Coating

Powder coating is a dry finish for metal. It makes a thick, strong layer. Lasers can take off powder coating by heating and turning it into gas.

E-Coating

E-coating, or electrocoating, keeps metal from rusting. You see it in cars and appliances. Laser removal can take off e-coating without hurting the metal.

Phosphate Coating

Phosphate coatings get metal ready for paint or stop rust. Lasers can take off these coatings so you can treat the metal again.

Insulating Coating

Insulating coatings keep out heat and electricity. You see them in power plants and electronics. Lasers can take off these layers safely and quickly.

- In aerospace, you may need to take off branding or protective coatings.

- In car factories, lasers help take off dangerous coatings, like those with lead or asbestos.

- Power plants use lasers to take off coatings that must be removed safely and fast.

Paints Less Suitable for Laser Removal

Some paints do not work well with laser removal. Some have chemicals that do not react well to lasers. For example:

- Paints with hydrocarbons or siloxanes may not come off well. The laser may not take them off all the way.

- Some pigments, like lead white and vermilion, can change color or disappear when hit by a laser. You may need to use other ways first, like micro-airabrasion.

- If you try to take off vermilion pigment with a laser, you might see color changes or lose the paint.

Note: Always test a small spot before using a laser on a new paint. This helps you avoid damage or bad results.

You can use a laser to take off acrylic, epoxy, polyurethane, enamel, latex, powder coatings, e-coating, phosphate, and insulating coatings. Some special coatings in aerospace and car making also come off well. But paints with some pigments or chemicals may not work. Always check the paint and test first to get the best results.

Laser Paint Removal Process

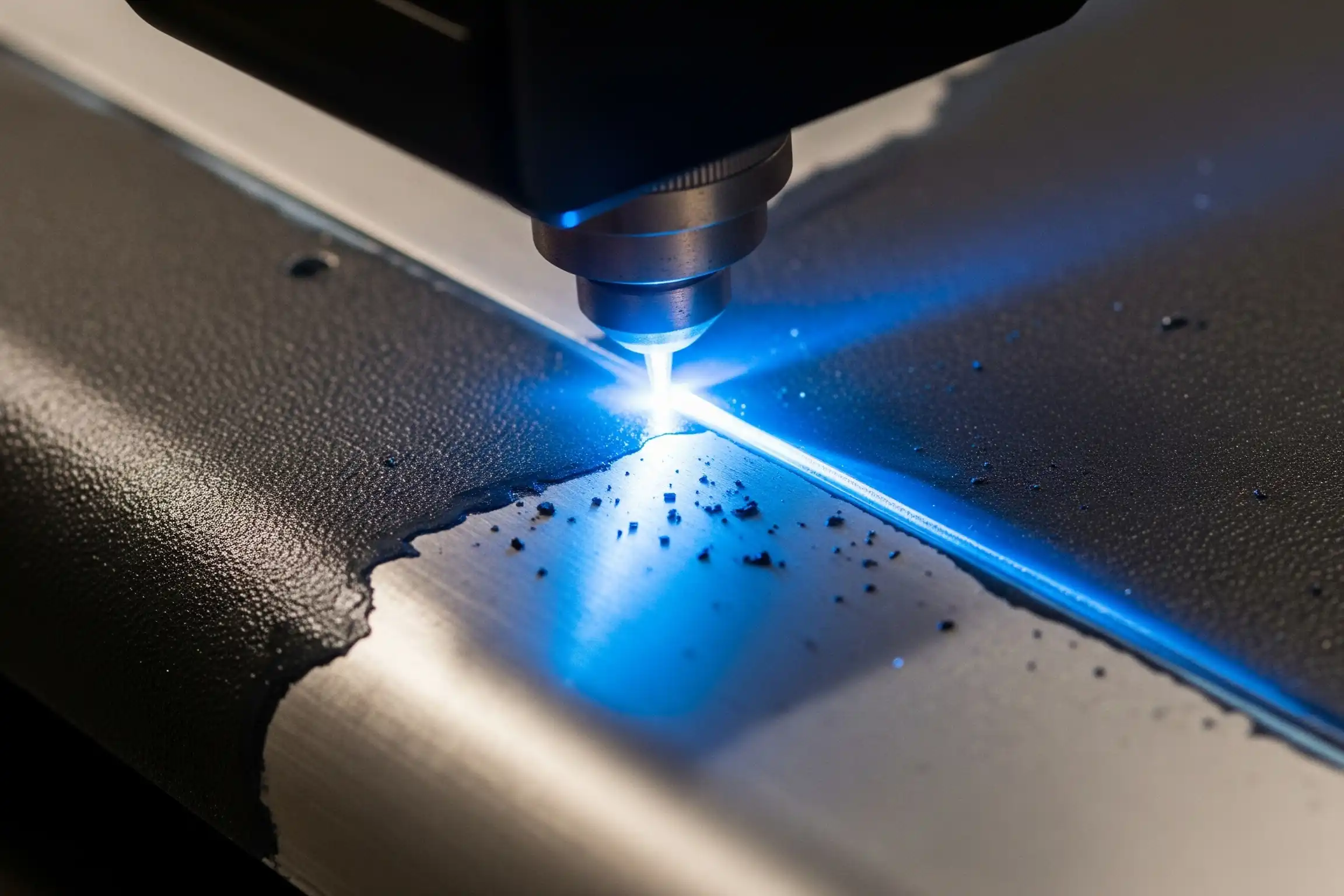

How Laser Ablation Works

Laser ablation is a process that uses a pulsed laser to remove paint from a surface. When you point the laser at the paint, it delivers energy in short bursts. This energy heats the paint quickly. If the energy is strong enough, the paint turns into vapor or gas and leaves the surface. Scientists call this the ablation threshold. You need to reach this level for the paint to come off cleanly. If you do not reach the threshold, the paint stays in place. If you go too high, you might damage what is under the paint. The goal is to use just enough energy to remove the paint without harming the surface.

Tuning Lasers for Different Paints

You can adjust the laser to work better with different types of paint. Each paint reacts in its own way to the laser. Some need more power, while others need less. The laser’s wavelength, pulse duration, and power all matter. For example, a study showed that using a continuous wave diode laser on epoxy polyester paint works best when you find the right power and time. Too little power does not remove the paint. Too much can hurt the surface. Another study found that high repetition rates help remove paint and primer faster. The table below shows how different lasers and settings work with different paints:

| Study | Laser Type | Paint Type | Key Findings |

|---|---|---|---|

| Barletta et al. | CW Diode Laser | Epoxy Polyester | Best removal at the right power and time; too little or too much is not good. |

| Schmidt et al. | CW Diode Laser | Epoxy Resin, Chlorinated Rubber | Removal rate goes up with more power; full removal possible. |

| Coutouly et al. | Pulsed CO2 Laser | Synthetic Resin | Works the same on aluminum and steel. |

| Brygo et al. | Nd:YAG Laser | Marine Paint | Some settings give low removal and rough surfaces. |

| Roberts et al. | Various | Paint and Primer | High repetition rate makes removal faster. |

Tip: Always test your laser settings on a small area first. This helps you find the best setup for your paint and surface.

Factors Affecting Effectiveness

Many things can change how well laser paint removal works. The thickness of the paint is important. Thick or dark coatings need more energy. The type of surface under the paint also matters. Soft metals, like aluminum, need short laser pulses to avoid heat damage. The shape of the object can make a difference. If you have a complex shape, you may need to use a smaller laser spot and move slowly. Cleanliness is key. Good fume extraction keeps the air and optics clean during the process.

| Factor | What You Set | Why It Matters |

|---|---|---|

| Coating type | Power and frequency | Thick or dark paint needs more energy |

| Substrate | Pulse width | Soft metals need short pulses to avoid damage |

| Geometry | Scan pattern | Complex shapes need small spots and slow moves |

| Throughput | Speed | Faster speed needs higher power |

| Cleanliness | Fume extraction | Keeps optics and air clean |

Research shows that the thermal stress from the laser is the main reason paint comes off. The material under the paint, like metal or plastic, changes how the laser works. For example, removing epoxy polyester paint from aluminum works best when you control the heat from the laser. Always think about the types of paint and the surface before you start.

Suitable Surfaces for Laser Removal

Metals

Laser paint removal works on many metals. Metals can take the heat from lasers without getting hurt. Here are some metals that work best with this method:

- Steel: Steel is used in buildings, cars, and machines. Lasers take paint off steel fast and leave it clean.

- Aluminum: Airplanes, cars, and bikes often use aluminum. Lasers remove paint from aluminum and keep the metal safe.

- Copper: Copper is found in wires and pipes. Lasers can take paint off copper without scratching it.

You get a smooth finish on these metals with lasers. You do not need strong chemicals or rough tools. This makes laser removal safe and good for metal jobs.

Non-Metals (Wood, Glass, Masonry)

Lasers can also take paint off some non-metals. You must use less power so you do not hurt the surface. Here is what you should know about each one:

- Wood: Lasers take paint off wood without burning it. This is great for fixing old furniture and cabinets. The wood keeps its look and you do not use harsh chemicals.

- Glass: Lasers can clean paint off glass. Using less power stops cracks or marks. This helps you clean windows or art glass safely.

- Masonry: Brick, stone, and concrete have tiny holes. Lasers take paint off masonry and do not leave stains. The surface keeps its real feel.

Tip: Always get a trained person for non-metal jobs. The right settings stop color changes or heat damage.

Graffiti and Wall Paints

Laser removal works well for graffiti and wall paint. You can use it on brick, concrete, and painted walls. It helps thin black marker lines and remove black spray paint. Here is what you should know:

| Challenge/Success | Description |

|---|---|

| Effectiveness of Laser Cleaning | Laser cleaning works better than old ways for graffiti. |

| Equipment Adaptability | Laser tools are not easy to use everywhere yet. |

| Time-Consuming Process | Laser cleaning takes a long time, which can slow you down. |

| Need for Chemical Integration | Best results come when you use chemicals after lasers to clean up. |

| Success Rate | Fiber lasers work well for thinning black markers and removing black spray paint. |

You get the best results if you use lasers and chemicals together for hard graffiti. Laser removal is exact for cleaning walls, but it can take longer than other ways.

Surface Condition Considerations

When you plan to use laser paint removal, you need to look closely at the condition of the surface. The state of the surface changes how well the laser works. Clean, smooth surfaces give you the best results. If you see rust, corrosion, or bumps, you may face problems.

Laser cleaning works well because it does not touch the surface. You can remove paint, rust, and other layers without scratching the material. You can adjust the laser’s wavelength and pulse duration to match the job. This helps you take off heavy oxides or thin films. You get a clean surface that is ready for welding or new paint.

Surface roughness matters a lot. Scientists use a number called Ra to measure how rough a surface is. If the surface is rough, the laser may not remove all the paint or oxide. You might see spots where paint stays. This uneven cleaning can lower the quality of your work. You may notice problems with how the surface looks or how it works later.

Tip: Always check for bumps, pits, or rust before you start. You can use a brush or cloth to clean loose dirt. If you see deep rust or thick paint, you may need to adjust the laser or use another method first.

Here are some things you should look for before using a laser:

- Corrosion: Rust or heavy oxidation can block the laser. You may need more power or extra passes.

- Unevenness: Bumps and pits make it hard for the laser to reach all areas. You may see leftover paint.

- Old Paint Layers: Thick or cracked paint can slow down the process. You may need to test a small spot first.

- Residue: Oil, grease, or dust can stop the laser from working well. Clean the surface before you start.

| Surface Issue | Impact on Laser Removal | What You Can Do |

|---|---|---|

| Rust/Corrosion | Needs more energy; may leave spots | Use higher power or pre-clean |

| Uneven Surface | Uneven cleaning; paint may stay | Adjust laser or use manual cleaning |

| Thick Paint | Slower removal; may need testing | Test a small area first |

| Dirt/Residue | Blocks laser; lowers quality | Clean before starting |

You need to know that surface condition affects more than just looks. If you leave paint or rust behind, you may see problems with corrosion resistance or wear. The surface may not work well for new paint or welding. You get the best results when you start with a clean, smooth surface and adjust the laser for each job.

Benefits of Laser Paint Removal

Precision and Control

Laser paint removal lets you work with great accuracy. You can pick which paint layers to take off. This means you can choose how thick the layer is. The surface under the paint stays safe. Laser ablation uses a strong beam to break up paint and rust. You can change the laser settings for each paint type. This helps when you work on fragile things, like art or airplane parts. You can clean soft or heat-sensitive materials without touching them. The laser uses light to turn paint into gas, so the finish looks clean.

- You only take off the layer you do not want.

- The original surface stays safe.

- You can work on small designs or sharp corners.

- You do not need harsh tools or chemicals.

Environmental and Safety Advantages

Laser paint removal is better for the environment and safer for people. You do not make extra waste like sandblasting or using chemicals. You do not need sand or other rough stuff, so you make less trash. Laser machines suck up dust and fumes to keep the air clean.

| Environmental Benefit | Description |

|---|---|

| Reduction of hazardous waste | No chemical solvents, so less waste. |

| CO₂ emissions reduction | Steel mills cut CO₂ by 85% after using lasers. |

| Water savings | No water is used, so you save all of it. |

| Solid waste reduction | You can lower solid waste by up to 95%. |

Laser cleaning also makes the workplace safer. You do not have to use toxic chemicals or breathe in dust. The process is safe and only needs simple safety gear. You do not need a special plan for exposure.

| Aspect | Laser Cleaning | Sandblasting |

|---|---|---|

| OSHA Compliance | Low risk, basic safety gear | Needs a plan for exposure |

| Environmental Impact | No toxic waste | Makes dangerous waste and dust |

| Operator Safety | No chemical fumes or dust | High risk for breathing problems |

You get a safer place to work and help the planet.

Surface Protection

Laser paint removal keeps the surface safe compared to other ways. The laser does not touch the material, so you do not scratch it. You keep small details and the original look. Laser cleaning leaves the surface ready for new paint.

| Property | Laser Removal | Chemical Stripping | Mechanical Methods (Sanding) |

|---|---|---|---|

| Surface Impact | No damage | Can leave residue | Can scratch the surface |

| Effect on Details | Keeps patterns | Can blur details | Can ruin fine details |

| Waste Product | Dust and fumes | Toxic sludge | Dust in the air |

You can use lasers for art, cars, or old buildings. The surface keeps its real look and feel. You do not have to worry about leftover chemicals or scratches.

Tip: Always test a small spot first. This helps you get the best results for your surface and the paint you want to remove.

Limitations and Drawbacks

Laser paint removal has many good points, but there are some downsides. You should know about these before you start. Knowing the limits helps you see if this method is right for your job.

Cost Factors

Laser paint removal machines can be very expensive. Small, portable machines cost a few thousand dollars. Big machines for factories can cost tens or even hundreds of thousands. The price changes with the power and size of the machine. Here is a table that shows the usual prices for different machines:

| Equipment Type | Price Range (USD) |

|---|---|

| Smaller, portable units | A few thousand |

| Larger, industrial systems | Tens to hundreds of thousands |

Machines with more power cost more money. Stronger machines can do bigger jobs.

| Power | Price (USD) | Best For |

|---|---|---|

| 1500W | $2,985 – $3,435 | General industrial paint removal |

| 2000W | $3,415 – $4,420 | Mid-heavy duty jobs |

| 3000W | $4,845 – $6,900 | Heavy industrial usage |

You also have to think about other costs. If you have a big area, you need a stronger machine. This makes the job cost more. Some paints take longer to remove, which adds to the price. If the surface is damaged, you need to do more work. You also pay for the people who run the machines and get the surface ready.

- Surface area: Bigger jobs need stronger machines.

- Type of coating: Some coatings take longer to remove.

- Surface condition: Damaged surfaces need more work.

- Labor: Skilled operators increase costs.

Paint and Surface Compatibility

Laser paint removal does not work for every job. The paint and the surface must work well with the laser. If the paint and surface are too much alike, the laser may not work well. You have to set the laser just right. Some paints and surfaces do not react well to the laser. You might see spots where the paint stays or need to go over it again. Always test a small spot first to see what happens.

Equipment and Skill Requirements

You need special skills to use laser paint removal machines. You must know how lasers work and follow safety rules. You have to learn how to use and take care of the machine. Training and certificates help you stay safe. You should know about safety at work and what to do in an emergency. Here are some skills you need:

- Understanding laser technology

- Safety protocols and personal protective equipment (PPE)

- Machine operation and maintenance

- Continuous learning and certifications

- Emergency preparedness

You also need hands-on skills. You must know how lasers work and how to use the machine. You have to follow safety and environmental rules. You need to check and fix the machine often to keep it working.

Laser paint removal is not easy. You need the right machine, skills, and knowledge to do a good job. If you do not have these, you could have problems or spend more money.

Assessing Paint and Surface

Before you start laser paint removal, you need to know what kind of paint you have and what surface you are working with. This helps you get the best results and avoid damage.

Identifying Paint Types

You can find many types of paint on different surfaces. Each paint reacts in its own way to laser removal. You might see acrylic, epoxy, polyurethane, enamel, or latex paint. Some surfaces have powder coating or e-coating. You need to look at the color, texture, and shine of the paint. Sometimes, you can use a small knife to scrape a hidden spot. If the paint comes off in flakes, it might be enamel or latex. If it feels rubbery, it could be polyurethane. You can also check old records or ask the manufacturer. Knowing the paint type helps you pick the right laser settings.

Tip: If you are not sure about the paint, take a photo and ask a paint store or a professional for help.

Testing a Small Area

You should always test a small area before you use the laser on the whole surface. This step helps you see how the paint and surface react. You can follow a simple process to make sure you get good results:

| Step | Description |

|---|---|

| 1 | Work with a laser company to choose the right laser power, pulse time, and spot size for your paint and surface. |

| 2 | Use the laser on a small, hidden spot. Check if the paint comes off and if the surface stays safe. Change the settings if needed. |

| 3 | When you find the best settings, use them for the whole job. Make sure you keep the same method for every part. |

Testing a small area lets you avoid mistakes. You can see if the laser leaves marks or misses spots. You can also check if the paint changes color or if the surface gets too hot. If you see problems, you can stop and try a new method.

Note: Always wear safety gear and keep the area clean when you test.

Consulting Professionals

Sometimes, you need help from experts. Professionals know what to look for and how to use the laser safely. You should check if the company or person has the right skills. Look for these key areas:

| Key Areas of Competence | Description |

|---|---|

| Management of Hazardous Paint Removal Projects | Shows they can handle jobs with safety and care. |

| Technical Capabilities Related to Hazardous Paint Removal | Proves they have the right tools and know-how. |

| Personnel Qualifications and Training | Means their team has the right training and skills. |

| Safety and Environmental Compliance Programs | Tells you they follow safety and environmental rules. |

A good professional will answer your questions and show you their training. They will also have a plan for safety and waste. You can ask for proof of their work on similar jobs. This helps you trust that your project will go well.

Tip: Always ask for a written plan and check reviews before you hire a professional.

Safety Considerations

Laser paint removal uses strong technology. You need to follow safety steps. Protect yourself and others nearby. The right gear and setup help you stay safe.

Personal Protective Equipment

You must wear special gear for laser paint removal. This gear keeps you safe from burns, fumes, and eye harm. Here is what you should wear:

- Laser Safety Goggles – These goggles block the laser’s light. Use goggles with the right OD for your laser’s wavelength.

- Flame-Resistant Clothing – Wear clothes that cover you and resist fire. This keeps your skin safe from heat and sparks.

- Thermal-Protective Gloves – Wear gloves that can take high heat. These protect your hands from hot things.

- Face Shields – A face shield gives extra safety for your face. It helps if there is laser scatter or reflection.

- Respiratory Protection – If you see dust or fumes, wear a mask or respirator. This stops you from breathing in bad stuff.

Tip: Always check your gear before you start. Replace broken gear right away.

Ventilation and Fume Control

Laser paint removal can make fumes and tiny bits. You need good airflow to keep the air clean. Good fume control keeps you healthy and the tools working.

| Component | Description |

|---|---|

| Capture Hoods or Nozzles | Put these close to the work to catch fumes fast. |

| Flexible Ducting | Lets you move the hose to fit your work’s shape or spot. |

| HEPA and Activated Carbon Filters | HEPA filters catch tiny bits. Activated carbon filters take out gases and smells. |

| Adjustable Flow Control | Keeps suction steady without messing up the laser or cleaning. |

You should use air monitors too. These check for dust and gases all the time. They warn you if the air is not safe. This helps you find problems with airflow or filters before they get bad.

- Air monitors keep the workspace safe.

- Monitors help you spot broken systems or filter issues.

- Real-time alerts warn you about too much dust or fumes.

Safe Laser Operation

You must know how to keep laser work safe. The right setup and habits lower accident risks.

| Safety Measure | Description |

|---|---|

| Protective Eyewear | Protects your eyes from laser light. |

| Designated Laser Safe Area | Keeps laser use in a marked, safe space. |

| Minimal Safety Wear | Only wear the gear you need. |

Laser machines are easy to use, quiet, and reliable. They cost little to run and need little fixing. Always keep the laser in a safe spot. Only trained people should use it. Follow all safety signs and rules in the area.

Note: Never look at the laser beam. Keep others out of the laser area.

You can use lasers to take off many kinds of paint. These include:

- Acrylic, epoxy, polyurethane, alkyd, and fluorocarbon coatings

- Special coatings used in cars and airplanes

Laser removal works best if you match the paint and the surface. Studies show that things like how often you use the laser and the angle you hold it matter for good results.

| Benefits | Limitations |

|---|---|

| Safe for people and nature | Costs more at first |

| Makes little smoke | Needs good airflow |

| Does not touch the surface | Only works on some materials |

Think about these steps before you begin:

- Talk to an expert about your project.

- Try the laser on a small spot to see if it is safe and works well.

FAQ

What types of paint can you remove with a laser?

You can remove acrylic, epoxy, polyurethane, enamel, latex, powder coatings, e-coating, phosphate, and insulating coatings with a laser. Always test a small area first to check how the paint reacts.

What surfaces work best for laser paint removal?

You get the best results on metals like steel, aluminum, and copper. You can also use lasers on wood, glass, and masonry. Always check the surface condition before starting.

What safety gear do you need for laser paint removal?

You need laser safety goggles, flame-resistant clothing, thermal gloves, and a face shield. Use a respirator if you see dust or fumes. Always check your gear before you start.

What are the main benefits of using a laser to remove paint?

Lasers give you precise control. You protect the surface and avoid harsh chemicals. You make less waste and keep the work area safer for everyone.

What are the limits of laser paint removal?

Laser paint removal costs more at first. Some paints or surfaces do not work well with lasers. You need special skills and training to use the equipment safely.

What should you do before starting laser paint removal?

You should identify the paint type and surface. Test a small area with the laser. Clean the surface and check for rust or bumps. Ask a professional if you are unsure.

What happens if you use the wrong laser settings?

You might damage the surface or leave paint behind. Always start with a test spot. Adjust the laser settings until you see clean removal without harming the material.

See also

How to Operate a Handheld Laser Cleaning Machine Safely

How to combine laser cleaning machine with industrial robots

What You Need to Know About Laser Cleaning Machine Certification

What Is the Range of Laser Cutting Thickness for Common Materials