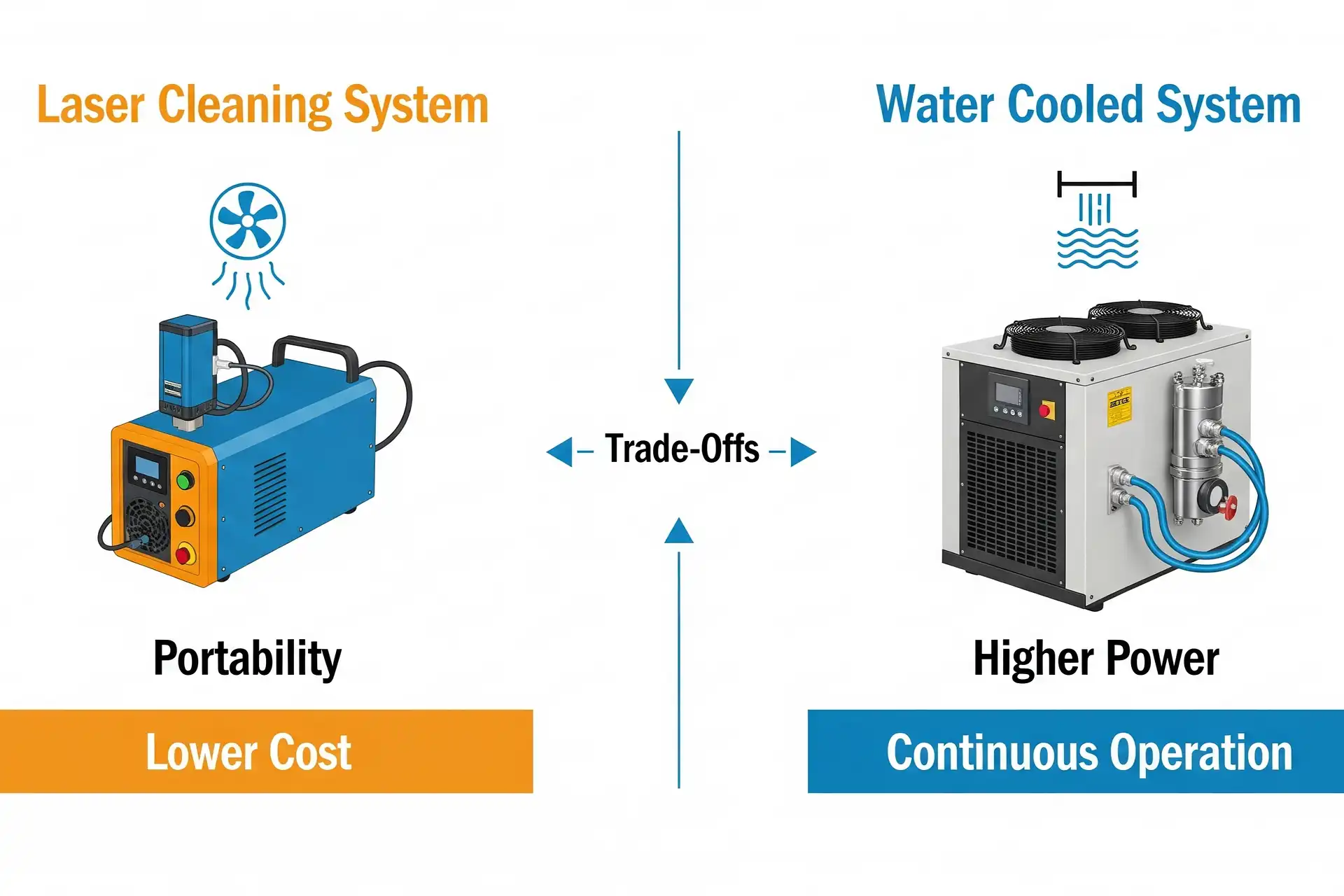

If you want something easy to move and use, pick air-cooled systems. Water-cooled systems are better for tough jobs and long cleaning times. What you choose depends on what matters most to you. You might care about how well it works, how much it costs, how hard it is to take care of, or how easy it is to move. Air-cooled laser cleaning tools help with fixing cars or taking off paint. Water-cooled systems are used in big factories or for airplane projects. Think about how much power you need and where you will work before you choose.

Key Takeaways

- Air-cooled systems are light and easy to carry. They work well for small jobs. You can move them without trouble.

- Water-cooled systems cool better than air-cooled ones. They are good for long and hard cleaning jobs. Factories use them for big tasks.

- Think about how much care each system needs. Air-cooled systems do not need much care. Water-cooled systems need checks for leaks and water levels.

- Look at how much money you want to spend. Air-cooled systems cost less to buy and fix. Water-cooled systems cost more.

- Pick the system that fits your job. Use air-cooled for quick jobs. Use water-cooled for tough jobs.

Quick Comparison

Key Differences

You can tell air-cooled and water-cooled laser cleaning systems apart by how they are built and how they work. The table below shows the main features for each one:

| Feature | Air-Cooled Laser Cleaners | Water-Cooled Laser Cleaners |

|---|---|---|

| Maintenance Requirements | Need less care; no water pumps or tanks | Need more care; must check for leaks and filters |

| Cooling Efficiency | Cooling is not as strong | Cooling works better |

| Portability | Small and light, easy to move | Bigger and heavier, best for staying in one place |

| Efficiency | Good for easy jobs, not for long use | Works well for hard jobs and long use |

| Cost | Cheaper to buy and keep working | Costs more because cooling is harder |

| Application Suitability | Great for simple, light jobs | Best for tough, long cleaning jobs |

This table makes it easy to see which system is good for your needs. Air-cooled systems use fans to cool the laser. Water-cooled systems use water pumps and tanks. This helps them cool better but makes them harder to use.

Main Advantages

When picking a laser cleaning system, you want to know what each one is best at. Here are the top reasons to pick each type:

- Air-Cooled Laser Cleaners

- They are easy to carry because they are small and light.

- You do not need to spend much time or money on care.

- They work well for small jobs, like cleaning tools or taking off rust.

- Water-Cooled Laser Cleaners

- They work well for long or hard jobs.

- You can use them for big cleaning jobs in factories or on large machines.

- They do not get too hot, even when used with lots of power.

Tip: If you want something easy to move for quick cleaning, air-cooled systems are a good choice. For big jobs that need lots of power, water-cooled systems work better.

Laser Cleaning Performance

Power and Consistency

When you pick a laser cleaning system, you should know how strong it is and if it works well all the time. Power is important because it shows how quickly you can clean things. It also tells you what jobs the system can do. Consistency means the system does not get too hot or slow down.

Here is a table that shows the highest power for each system:

| System Type | Maximum Power Rating |

|---|---|

| Air-Cooled | 500W |

| Water-Cooled | 1500W |

Water-cooled systems can use more power. You can use them for hard cleaning jobs. They stay cool even if you use them for a long time. Air-cooled systems are better for easy jobs. They might get too hot if you use them for big jobs or for many hours.

Note: If you need to clean big areas or thick rust, water-cooled systems give you more power and work better for a long time.

Material Suitability

Laser cleaning can be used on many things. You need to pick the right system for your job. Some systems clean metal, paint, or rust. Others are better for soft surfaces or special dirt.

Look at the table to see how cleaning methods work on different dirt:

| Cleaning Technique | Effectiveness on Contaminants |

|---|---|

| Steam Laser Cleaning | Good for removing dust and small bits |

| Dry Laser Cleaning | Works well for cleaning oil and stains |

Steam laser cleaning helps you take away dust and tiny pieces. Dry laser cleaning is good for oil, grease, or stains from living things. You should choose the best way to clean based on what you need.

- If you clean metal tools or car parts, dry laser cleaning can take off rust and paint.

- If you clean things in food factories or labs, steam laser cleaning helps you remove small bits.

Laser cleaning is safe and does not use chemicals. It keeps the material safe and does not hurt it. You also save time because laser cleaning is quick and accurate.

Tip: Always check what material you have and what kind of dirt is on it before you pick your laser cleaning system. This helps you clean better and keeps your tools working well.

Reliability and Maintenance

Cooling Efficiency

You want your laser cleaning system to work well every time you use it. Cooling efficiency plays a big role in this. Air-cooled systems use fans to move heat away from the laser. These fans work best in clean, cool spaces. If you use your machine in a hot or dusty place, the fans might not cool the laser enough. This can make the system slow down or stop working for a while.

Water-cooled systems use water to take heat away from the laser. Water moves heat better than air. This means water-cooled systems keep the laser at a steady temperature, even during long or tough jobs. You can use these systems for hours without worrying about overheating. If you need to clean large areas or work in a factory, water-cooled systems give you more reliable cooling.

Tip: If you plan to use your laser cleaning machine for long periods or in hot places, water-cooled systems offer better cooling and help prevent breakdowns.

Maintenance Needs

You should think about how much care your system needs. Air-cooled systems have fewer parts. You only need to check the fans and clean out dust. This makes them easy to take care of. You can fix most problems quickly.

Water-cooled systems need more attention. You must check the water level, look for leaks, and change filters. If you forget these steps, the system might overheat or break. You may need to call a technician for some repairs.

Here is a quick list to help you compare:

- Air-cooled: Clean fans, remove dust, check airflow.

- Water-cooled: Check water, inspect hoses, replace filters, watch for leaks.

Note: Regular maintenance keeps your laser cleaning system safe and working well. Always follow the care guide from the maker.

Cost and Portability

Initial and Operating Costs

When you look at the price of laser cleaning systems, you see a big difference between air-cooled and water-cooled models. Air-cooled systems cost less to buy and keep running. Water-cooled systems cost more because they need extra parts for cooling and more care over time.

Here is a table that shows the average price for each type:

| System Type | Initial Purchase Cost |

|---|---|

| Water-Cooled | $8,000 – $10,000 |

| Air-Cooled | $4,600 – $5,500 |

You also need to think about how much it costs to use and fix these machines. Air-cooled systems use less energy and need less care. You clean the fans and check for dust. Water-cooled systems need you to check water levels, look for leaks, and change filters. This means you spend more money and time on care.

- Air-cooled systems:

- Lower maintenance costs

- Less energy use

- May slow down if used for long, hard jobs

- Water-cooled systems:

- Higher maintenance costs

- More energy use

- Stay strong during long, tough jobs

Tip: If you want to save money, air-cooled systems help you spend less at the start and over time. Water-cooled systems cost more but work better for big jobs.

Portability Factors

Portability matters when you need to move your laser cleaning machine. Air-cooled systems are easy to carry. They do not need water pumps or tanks. You can use them in many places, like workshops or outside.

Water-cooled systems are bigger and heavier. They have more parts for cooling. You use them best in one spot, like a factory.

Look at the weights of different machines:

| System Type | Weight (KG) |

|---|---|

| Hand-held Fiber Laser Cleaning Machine (1000W) | 150 |

| Hand-held Fiber Laser Cleaning Machine (1500W) | 150 |

| Hand-held Fiber Laser Cleaning Machine (2000W) | 180 |

| Suitcase Type Portable Laser Cleaning Machine (100W) | 28 |

- Air-cooled systems:

- Compact design

- Easy to move for field work

- Suitcase type weighs only 28 kg and fits on trains or planes

- Water-cooled systems:

- Heavy and bulky

- Best for staying in one place

Note: If you need to travel or work in different places, air-cooled systems give you more freedom. Water-cooled systems work best when you do not need to move them.

Laser cleaning gives you choices for cost and portability. You pick the system that fits your budget and your work style.

Laser Cleaning Applications

Industrial Use

Water-cooled laser cleaning systems are used in big factories. These machines clean parts in cars, planes, and energy plants. Water-cooled systems keep the laser cool for long jobs. They help you clean faster and stop less often. Workers stay safer because these systems lower toxic substances. If you need to clean large machines or use lots of power, water-cooled systems work best.

- Water-cooled systems keep lasers cool for long jobs.

- They can handle more heat, so you use them for hours.

- You see them where cleaning must be quick and safe.

Tip: Pick water-cooled laser cleaning for big factories or when you need strong power and steady work.

Field and Workshop Use

Air-cooled laser cleaning systems are good for small shops or outdoor jobs. These machines are light and easy to carry. You can set them up fast for work on-site or far away. Air-cooled systems are best for short jobs and places you cannot control well.

Here is a table to show how air-cooled and water-cooled systems work for field jobs:

| Feature | Air-Cooled Systems | Water-Cooled Systems |

|---|---|---|

| Portability | Easier to move and set up | Bigger and harder to move |

| Heat Dissipation | Not as good at cooling | Cools better and handles more heat |

| Ideal Use | Good for moving and field jobs | Best for staying in one place |

| Power Application | Not great for high power | Works well with high power |

| Typical Use Cases | On-site jobs, remote work | Big jobs in steady places |

Water-cooled systems are harder to use in small shops or outside. You need good conditions and must check them often. Sometimes you need antifreeze. These machines do not like hot or wet places. If you work near things that can catch fire, you must be careful because sparks can be dangerous.

- Air-cooled systems are simple to use in many places.

- Water-cooled systems need more care and steady conditions.

Note: For jobs that move or small shops, air-cooled laser cleaning systems help you work quickly and safely.

Pros and Cons

Air Cooled Systems

Air cooled systems are light and easy to move. They are good for small jobs and do not need much care. You do not have to check water pumps or worry about leaks. Many people think these systems are better for the environment because they do not waste water.

Here is a table that shows the main good and bad points:

| Advantages | Disadvantages |

|---|---|

| Portability: Compact and lightweight design | Limited cooling efficiency for heavy-duty tasks |

| Lower maintenance requirements | Potential inadequacy for high-temperature use |

| Environmental sustainability: No water waste |

Air cooled systems can be loud. They use fans that make more noise than water-cooled systems. If you work in a quiet place, this noise might bother you. Air cooled systems do not cool as well when it is hot. They might slow down or stop if you use them for a long time in high heat.

Tip: Pick air cooled systems if you need to move your machine a lot and want easy care.

Water-Cooled Systems

Water-cooled systems give strong cooling. You can use them for big jobs or when you need to clean for many hours. These machines work best in factories or places where you need a lot of power. They also make less noise than air cooled systems.

Look at this table for the main good and bad points:

| Pros of Water-Cooled Systems | Cons of Water-Cooled Systems |

|---|---|

| Better cooling efficiency | Higher maintenance requirements |

| Suitable for heavy-duty applications | Less portability |

| Ideal for extended use in high-temperature tasks | Requires upkeep to maintain cooling system |

Water-cooled systems need more care. You must check water levels, look for leaks, and change filters. If you use them in a place with lots of moisture, water can form on the parts. This can cause short circuits or rust. Air cooled systems do not have this problem.

- Water-cooled systems work better in hot places.

- Air cooled systems are less likely to have problems in wet air.

Note: Choose water-cooled systems if you need strong, steady power and do not need to move your machine often.

You now know the main differences between air-cooled and water-cooled systems. Air-cooled models work best for small jobs and easy moving. Water-cooled systems handle tough tasks and long hours. Think about what matters most to you before you choose a laser cleaning system. You can talk to suppliers or try out machines to see what fits your needs.

FAQ

What is the main difference between air-cooled and water-cooled laser cleaners?

You will see that air-cooled systems use fans to keep the laser cool. Water-cooled systems use water and pumps. Water-cooled machines handle more heat and power.

Can I use an air-cooled laser cleaner for long jobs?

You can use air-cooled systems for short or light jobs. If you run them for a long time, they may overheat. For long or tough jobs, water-cooled systems work better.

Which system is easier to maintain?

You will find air-cooled systems easier to maintain. You only need to clean the fans and remove dust. Water-cooled systems need you to check water levels, look for leaks, and change filters.

Are air-cooled laser cleaners safe to use outdoors?

Yes, you can use air-cooled laser cleaners outdoors. They are light and easy to move. Make sure you keep them away from rain and dust for best results.

How do I choose the right system for my needs?

Think about your job size, how often you move the machine, and your budget. Air-cooled systems fit small, quick jobs. Water-cooled systems work best for big, heavy-duty tasks.

See also

The Ultimate Guide to Parameter Requirements for Fiber Laser Cleaning

Exploring the Science Behind Ship Rust Removal Using Lasers

What must be checked before starting the laser cleaning machine