When choosing a cleaning tool for your work, it’s important to consider whether a continuous laser cleaning machine or a pulse laser cleaning machine is the right fit. For example, if you work in a car factory or restore antique art, your decision between a continuous laser cleaning machine and a pulse laser cleaning machine will impact the speed, safety, and cost of your project. Large factories typically rely on continuous laser cleaning machines for heavy-duty cleaning tasks. In terms of market share, North America leads with 35%, followed by Europe at 30%, and Asia-Pacific at over 25%. Matching the right machine to your specific job and material is crucial. Take the time to learn whether a continuous laser cleaning machine or a pulse laser cleaning machine is best for your needs.

- Continuous laser cleaning machines are most commonly used in large factories

- Market share: North America (35%), Europe (30%), Asia-Pacific (25%)

Key Takeaways

- Pick a continuous laser cleaning machine for big, hard jobs. It cleans large areas fast and well.

- Use a pulse laser cleaning machine for gentle items. It is precise and keeps fragile surfaces safe from heat.

- Think about the material before you pick a machine. Continuous lasers work best on metals. Pulse lasers are good for non-metals and soft materials.

- Look at what you need to clean. Continuous machines are quicker. Pulse machines give you more control for small details.

- Know the costs. Continuous machines cost less at first. They may use more energy and cost more to run.

- Always check if the material is sensitive. Change the machine settings so you do not harm it while cleaning.

- Use the checklist to help you choose. Think about what you need to clean, the material, and safety.

- Learn about new trends. New laser cleaning machines are safer and work better.

Quick Answer: Which to Choose

Summary Table

You might ask which machine is best for your cleaning job. The table below shows different situations and which machine works well. This makes it easier to pick quickly.

| Scenario Description | Recommended Machine Type |

|---|---|

| Large-area cleaning tasks | Continuous Laser Cleaning Machine |

| Light to medium contamination (dust, grease, thin paint layers) | Continuous Laser Cleaning Machine |

| Suitable for flat or large workpieces (e.g., steel plates, pipelines) | Continuous Laser Cleaning Machine |

| Replacing sandblasting for heavy equipment (e.g., dump trucks, snowplows) | Continuous Laser Cleaning Machine |

| Cleaning of precision components | Continuous Laser Cleaning Machine |

| Delicate surface cleaning (artwork, electronics) | Pulse Laser Cleaning Machine |

| Removing thick rust or paint from sensitive materials | Pulse Laser Cleaning Machine |

| Restoration of antiques or historic items | Pulse Laser Cleaning Machine |

| Cleaning microelectronics or medical devices | Pulse Laser Cleaning Machine |

Tip: If you need to clean big, flat surfaces or heavy machines, you will probably use a continuous laser cleaning machine. If you work with fragile things or need very careful cleaning, a pulse laser cleaning machine is a better choice.

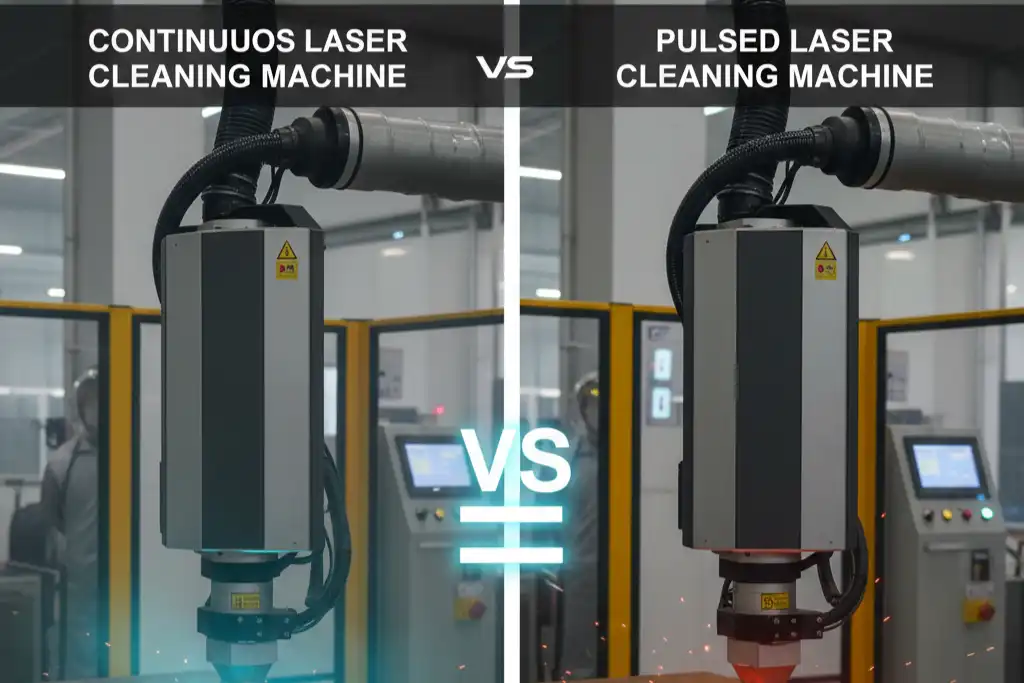

Continuous Laser Cleaning Machine and Pulse Laser Cleaning Machine: Overview

There are two main cleaning machines. One is a continuous laser cleaning machine. The other is a pulse laser cleaning machine. Each machine works in its own way. They are good for different cleaning jobs. Knowing how these machines work helps you pick the right one.

What Is a Continuous Laser Cleaning Machine

A continuous laser cleaning machine uses a steady beam of laser light. The beam shines on the surface you want to clean. The laser heats up the dirt, rust, or paint. This makes it come off. You can use this machine on big surfaces. It works well on steel plates and heavy equipment. The machine cleans fast and covers large areas quickly. It can make a lot of heat. This heat might hurt sensitive materials. Most factories use continuous laser cleaning machines for hard jobs. Speed is more important than gentle cleaning for them.

What Is a Pulse Laser Cleaning Machine

A pulse laser cleaning machine works in a different way. It sends out short bursts of laser energy. These bursts hit small spots for a short time. This gives you more control and accuracy. You can clean tiny details or fragile surfaces. Artwork and electronic parts are good examples. The machine does not make much heat. This keeps delicate things safe. Pulse laser cleaning machines cost more money. They protect sensitive materials and do a better job for careful cleaning.

Note: The biggest difference is how each machine gives out energy. One uses a steady beam. The other uses quick bursts.

Here is a table that shows the main differences:

| Parameter | Continuous Laser Cleaning | Pulse Laser Cleaning |

|---|---|---|

| Laser Operation | Constant, steady beam | Short, high-energy bursts |

| Cleaning Speed | Fast for large areas | Slower, more precise |

| Heat Generation | Higher | Minimal |

| Precision Level | Moderate | High |

| Cost Efficiency | Lower initial cost | Higher upfront cost |

| Material Suitability | Metals, thick coatings | Delicate, sensitive items |

When you look at both machines, you see they have special uses. Think about your material and cleaning needs before you choose.

Key Differences

How They Work

There are two main laser cleaning machines. Each one removes dirt in its own way. A continuous laser cleaning machine uses a steady beam of light. The beam hits the surface and heats up the dirt. The heat makes the dirt or rust break off. This machine works well for big surfaces and hard jobs.

A pulse laser cleaning machine works in another way. It sends out short bursts of laser energy. These bursts hit small spots for a short time. You can control where the energy goes. This helps you clean delicate surfaces without hurting them. You can use it for artwork, electronics, or thin coatings.

If you need to clean a large metal plate, use a continuous laser cleaning machine. If you want to clean a fragile antique, use a pulse laser cleaning machine.

Energy Delivery

How each machine gives out energy is important. It changes how well the cleaning works. Look at the table below to see the main differences:

| Feature | Continuous Laser Cleaning Machines | Pulsed Laser Cleaning Machines |

|---|---|---|

| Energy Emission | Steady beam of high-energy laser | Short bursts of concentrated energy |

| Heat Accumulation | More heat builds up, which can hurt the material | Less heat builds up, good for delicate things |

| Cleaning Efficiency | Good for big areas and tough stains | Works well for rust, oil, and thin layers with less damage |

| Industrial Suitability | Best for cleaning in factories | Better for things that can be hurt by heat |

A continuous laser cleaning machine gives a steady stream of energy. It builds up more heat. This can hurt sensitive materials. A pulse laser cleaning machine keeps heat low. You can clean fragile items safely.

Cleaning Process

The cleaning process depends on the machine you use. With a continuous laser cleaning machine, you move the laser over the surface. The steady beam melts and lifts thick rust, paint, or grime. You finish big jobs fast. You do not miss spots on large surfaces.

With a pulse laser cleaning machine, you work on small areas. The laser bursts remove thin layers without heating everything. You can clean tiny details and keep the base safe. You work slower but get more accuracy.

- Continuous laser cleaning machine and pulse laser cleaning machine have different strengths.

- Match the cleaning process to your material and job size.

Tip: Pick the machine that fits your cleaning needs. Big, tough jobs need speed and power. Delicate work needs control and safety.

Pros and Cons: Continuous Laser Cleaning Machine

When you look for cleaning tools, you want to know why a continuous laser cleaning machine is special. This machine has good points, but it also has some problems you should think about before you choose.

Advantages

Speed and Efficiency

A continuous laser cleaning machine can clean big surfaces fast. The laser beam works quickly and removes rust, paint, and dirt faster than many old ways. If you have a big job and need to finish soon, this machine helps you save time.

Lower Equipment Cost

Many people see that using a continuous laser cleaning machine costs less than other ways. You do not spend much on fixing things because the laser does not damage surfaces. You also do not need to buy chemicals or rough materials. Over time, you save money on repairs and supplies.

Large-Scale Cleaning

Factories and workshops use continuous laser cleaning machines for big cleaning jobs. You can use them on steel plates, pipes, and heavy machines. The machine cleans wide areas and does not miss spots. This is great for places that need to clean large items every day.

Tip: You can use this machine on metals, plastics, and glass. It works on many materials and gives you good accuracy.

Here is a table with more good points from experts:

| Advantage | Description |

|---|---|

| Versatility | Cleans many materials like metals, plastics, and glass. |

| High Precision | Removes only dirt and keeps important parts safe. |

| Environmental Friendliness | Does not use strong chemicals, so it is better for the environment. |

| Cost-Effectiveness | Makes equipment last longer and lowers repair costs. |

Disadvantages

Risk of Material Damage

You need to be careful about heat. The laser beam can get very hot. If you use it on soft materials, you might hurt the surface. Thin layers, porous things, and fragile items can get damaged by too much heat.

Not for Delicate Surfaces

Continuous laser cleaning machines are not good for delicate surfaces. If you try to clean antiques, electronics, or things with tiny details, you might harm them. You may need another way for these jobs.

Here is a table with common problems found in factories:

| Disadvantage | Description |

|---|---|

| High Costs | The first price for a laser cleaning machine is high compared to older cleaning machines. |

| Safety Risks | Workers must wear special goggles because the laser beam is strong and can be dangerous if you do not use safety gear. |

| Limitations in Cleaning Materials | Laser cleaning machines cannot clean everything, like barnacles, thick oil, and soft materials, which may need other cleaning ways. |

| Specific Material Challenges | – Barnacles: Hard to remove without hurting the surface. |

- Thick Oil: Needs many tries or other ways to clean well.

- Sensitive Materials: Can get damaged by too much heat from the laser.

- Porous Surfaces: May leave dirt because it is hard to clean deep holes. |

Note: Continuous laser cleaning machine and pulse laser cleaning machine have their own good and bad points. Pick the machine that fits your cleaning needs for the best results.

Pros and Cons: Pulse Laser Cleaning Machine

Advantages

Precision and Control

A pulse laser cleaning machine lets you clean with great care. The laser sends out quick bursts of energy. These bursts let you aim at tiny spots. You do not have to touch the surface. You can take off dirt, rust, or coatings from small places. This machine is good for careful jobs like microelectronics or artwork.

- You can aim the laser at just the spot you want.

- The machine takes off thin or thick layers very accurately.

- The laser does not touch the material, so there is no stress.

You can clean very thin oxide layers or thick paint. The base material stays safe. This makes the machine great for jobs that need precision.

Low Thermal Impact

Pulse laser cleaning machines make very little heat. You do not have to worry about burning things. The short bursts keep the temperature low. This protects fragile things like antiques or medical devices.

Tip: Pick a pulse laser cleaning machine for delicate cleaning. You keep the item safe and avoid heat damage.

Suitable for Sensitive Materials

You can use this machine on sensitive materials. It works well for electronics, artwork, and thin coatings. You do not hurt the surface. The laser does not touch the item, so it stays safe.

Here is a table that shows why pulse laser cleaning machines are good for sensitive jobs:

| Feature | Benefit |

|---|---|

| Non-contact cleaning | No scratches or damage |

| Low heat generation | Keeps fragile surfaces safe |

| High precision | Cleans only the needed area |

Pulse laser cleaning does not use chemicals. You make less waste and help the environment.

Disadvantages

Higher Cost

A pulse laser cleaning machine costs more to buy. The price is higher than other machines. You pay more at first, but you save money later. You do not need many supplies or chemicals. The machine lasts a long time and needs less fixing.

- The first cost is high.

- You spend less later because you use fewer supplies.

Slower Cleaning

Pulse laser cleaning machines work slower than continuous ones. You clean small spots at a time. Big jobs take longer to finish. You get more accuracy and safety, but it takes more time.

Note: Think about what you need to clean. If you want fast cleaning for big areas, each machine has its own strengths. For delicate work, the pulse laser cleaning machine is the better choice.

Cleaning Effectiveness

Performance on Contaminants

When picking a laser cleaning machine, you want to know how well it cleans rust, paint, and oil. Continuous laser cleaning machines use a steady beam of energy. This beam burns away thick rust and paint fast. You can clean big areas quickly. If you work in a factory or clean heavy equipment, this method works well.

Pulse laser cleaning machines work in a different way. They send out short, strong bursts of energy. These bursts lift away dirt gently and do not heat the material much. You can clean delicate things like artwork or electronics without hurting them. Pulse lasers are great for jobs that need careful cleaning.

Here is a table that shows how each machine works on different contaminants:

| Feature | Pulse Laser Cleaning | Continuous Laser Cleaning |

|---|---|---|

| Operation | Short, intense bursts of laser energy | Constant beam of laser energy |

| Effectiveness | Better for delicate or sensitive substrates | Quick removal of material, less precision |

| Heat Generation | Lower surface temperature (50°C – 96°C) | Higher surface temperature (up to 400°C) |

| Best Use Case | Precision work, protecting underlying material | Large-scale jobs, fast rust removal |

| Environmental Impact | Generates less fume and smoke | Higher heat may lead to more fumes |

You can see that continuous lasers are best for tough cleaning jobs. Pulse lasers give you more control and keep sensitive materials safe.

Tip: Use a pulse laser cleaning machine for fragile items. For big, dirty surfaces, a continuous laser cleaning machine saves time.

You should also remember these points:

- Pulse laser cleaning uses short bursts to gently remove dirt without hurting the surface.

- Continuous laser cleaning uses a steady beam to burn away dirt but makes more heat.

- Pulse lasers are best for careful jobs, while continuous lasers are better for big areas and fast cleaning.

Depth and Uniformity

You want your cleaning job to be even and thorough. Continuous laser cleaning machines cover wide surfaces with a steady beam. You get even results on big metal plates or pipes. The heat from the laser melts thick layers, so you do not miss spots. This method is good for deep cleaning.

Pulse laser cleaning machines focus on small areas. You can control how deep you clean by changing the laser bursts. This helps you clean just the top layer or go deeper if you need. You protect the base material and avoid damage. Pulse lasers give a smooth finish on delicate items.

Here are some things to remember:

- Continuous lasers give fast, deep cleaning for big jobs.

- Pulse lasers let you control cleaning, so you clean just enough.

- Both machines help you get even results, but you should pick based on your material and job size.

Note: Always match your cleaning machine to your project. You will get better results and keep your materials safe.

Material Compatibility

Metals and Alloys

Factories and workshops often need to clean metals and alloys. Continuous laser cleaning machines work well on many metals. These machines clean surfaces fast and remove rust, paint, or grease. The steady laser beam helps finish big jobs quickly.

Here are some metals and alloys that work best with continuous laser cleaning machines:

- Aluminum

- Cast Iron

- Iron (Steel, Carbon Steel, Stainless Steel)

- Nickel

- Titanium

- Zinc

- Metal Alloys

You can also use these machines on ceramics, concrete, limestone, and stone. Continuous lasers take off oil, grease, and coatings from these materials. You get a smooth finish and save time.

Tip: If you clean large metal parts or heavy equipment, continuous laser cleaning gives you speed and power.

Non-Metals

Sometimes you need to clean non-metal materials at work. Pulse laser cleaning machines help clean these surfaces without damage. The short bursts of energy keep fragile items safe.

Non-metals that work best with pulsed laser cleaning machines include:

- Plastics

- Wood

- Stone

- Ceramics

- Composites

- Polymers

- Walls

- Tiles

You can clean artwork, electronics, and delicate surfaces with pulse lasers. The machine does not touch the material, so you avoid scratches and burns. You get precise cleaning for small details.

Note: Pulse laser cleaning is a smart choice for non-metals and fragile items. You protect the surface and get better results.

Heat-Sensitive Materials

You must be careful when cleaning heat-sensitive materials. Continuous laser cleaning machines use a steady beam that makes a lot of power. This can cause overheating and damage if you do not control the settings. You need to check the material before you start cleaning.

Risks of using continuous lasers on heat-sensitive materials:

- High power can cause overheating.

- Sensitive materials may get damaged without careful control.

- Heat buildup increases the risk of harm.

To protect heat-sensitive materials, you should:

- Check the surface and material first.

- Change laser settings for each material.

- Use special steps to keep the material safe.

Pulse laser cleaning machines help you avoid these risks. The short bursts keep the temperature low and protect fragile surfaces. You get safe cleaning for antiques, electronics, and medical devices.

⚠️ Always check the material before you start cleaning. Adjust your machine settings to match the sensitivity of the item.

Typical Applications

Industrial Cleaning

Factories and workshops use laser cleaning machines a lot. If you work with big metal parts, you need a strong cleaning tool. Continuous laser cleaning machines help take off rust, paint, and grease from steel plates and pipes. These machines clean large surfaces fast. You save time and do not need many chemicals.

Many industries use continuous lasers for jobs like:

- Taking old coatings off machines

- Cleaning welding seams before and after joining metals

- Getting surfaces ready for painting or coating

- Removing rust from big vehicles like trains or ships

Continuous laser cleaning is good when you want speed for big jobs. The process keeps your workspace cleaner. It makes less dust and waste.

Restoration and Conservation

Museums and historic buildings need to protect fragile items. Pulse laser cleaning machines give you control and safety for these jobs. You can clean artwork, sculptures, and old artifacts without hurting them.

Pulse lasers, especially MOPA types, have many benefits:

- Precision: You can clean small spots gently. This helps you avoid heat damage to fragile relics.

- Portability: Many pulse laser machines are easy to carry. You can bring them to far places or move them in tight spaces.

- Safety: The cleaning does not touch the item. You do not scratch or wear down the surface.

When you pick a pulse laser for restoration, follow these steps:

- Choose a 200-500W pulse laser to clean dirt and keep the relic safe.

- Use air-cooled machines for outdoor work. They are flexible and need less fixing.

- Look for digital controls, like a focal length display. This helps you keep the right distance and protect the surface.

Note: Pulse laser cleaning lets you fix valuable items safely. You protect history and keep each piece safe.

Electronics and Precision Work

Electronics and small parts need gentle cleaning. Pulse laser cleaning machines give you control for these jobs. You can remove thin layers of oxide, dust, or residue from circuit boards and sensors. The short bursts of energy keep things cool, so you do not hurt sensitive parts.

Some common uses in this field are:

- Cleaning solder pads on printed circuit boards (PCBs)

- Removing tiny dirt from semiconductor wafers

- Getting surfaces ready for bonding or coating in medical devices

Pulse lasers help you clean with high precision. You do not scratch or change the shape of each part. This makes pulse laser cleaning a smart choice for electronics and fine mechanical parts.

Tip: Always test your cleaning method on a small spot first. This helps you find the best settings for your materials.

Choosing the Right Machine

Selecting the best laser cleaning machine for your job can feel confusing. You want to make sure you get the right tool for your materials and cleaning needs. This section helps you understand the most important factors and guides you through a simple decision process.

Key Factors

When you compare continuous laser cleaning machines and pulsed laser cleaning machines, you should look at several key points. Each factor affects how well the machine works for your project.

Material Type

You need to know what material you want to clean. Some machines work better on metals, while others protect delicate surfaces.

- Pulsed lasers send short bursts of light. These bursts create high peak power and keep materials cool. You can use pulsed lasers on thin metals, wood, and fragile items.

- Continuous wave lasers give a steady stream of energy. This can heat up the material and may damage sensitive parts. You should use these on tough metals and thick coatings.

Precision Needs

Think about how much control you need. If you want to clean tiny details or avoid harming the surface, you need high precision.

- Pulsed lasers help you clean small spots with care. You can protect the surface and avoid scratches.

- Continuous lasers work fast but may not offer the same level of control.

Speed and Scale

Consider how big your cleaning job is and how quickly you need to finish.

- Continuous laser cleaning machines clean large areas fast. You can remove heavy dirt and rust quickly.

- Pulsed laser cleaning machines work slower but give you more accuracy.

Budget

You need to plan your spending. The price and running costs can change your decision.

| Machine Type | Price Range | Operational Costs |

|---|---|---|

| Pulsed Laser Cleaning | $6,000 – $33,000 | Lower operational costs depending on application |

| Continuous Laser Cleaning | $3,000 – $7,500 | Higher operational costs due to energy consumption |

- Continuous laser cleaning machines cost less at first but use more energy.

- Pulsed laser cleaning machines cost more to buy but may save money over time.

Safety

You want to keep your workspace safe. Laser machines can be dangerous if you do not use them correctly.

- Pulsed lasers help preserve surface integrity and lower the risk of overheating.

- Continuous lasers may need extra safety steps because they create more heat.

Tip: Always wear proper safety gear when using any laser cleaning machine.

Decision Guide

You can use a checklist to help you choose the right machine. Answer these questions before you decide:

- What material do you need to clean?

- Is the surface delicate or tough?

- How big is the area you want to clean?

- Do you need high precision?

- What is your budget for buying and running the machine?

- What safety steps do you need to follow?

Here is a step-by-step process to guide your choice:

- Identify your cleaning needs. Write down what you want to clean and why.

- Look at the size, shape, and area of the parts.

- Check the type of material and how sensitive it is.

- Decide what kind of dirt or coating you need to remove.

- Review your current cleaning methods and how often you clean.

- Set your goal for cleaning speed and quality.

- Think about what happens to the part before and after cleaning.

- Learn about how each machine works in your workspace.

- Gather information and talk with others who use these machines.

- Compare continuous laser cleaning machine and pulse laser cleaning machine options based on your answers.

- Test power settings and see which machine fits your needs.

- Make your final choice and plan your next steps.

Note: If you follow this checklist and decision guide, you will find the best laser cleaning machine for your job.

Mistakes to Avoid

When you pick a laser cleaning machine, you want good results. Some people make mistakes that waste time and money. You can stop these problems if you know what to look for.

Overlooking Material Sensitivity

You need to think about what you are cleaning. Some things do not like heat or strong laser energy. If you forget this, you might ruin your stuff.

- Set the machine’s settings for the type of material you have.

- Plastics and rubber can melt or change shape if they get too hot.

- Some coatings and polymers can break or change when hit by too much laser energy.

Tip: Always check if your material can take the laser’s heat and power. Try the laser on a small spot first so you do not make a big mistake.

Do these things before you start:

- Write down what you want to clean and what you want it to look like after.

- Learn about the machine’s power, wavelength, and scan speed. Make sure these match what you need.

Ignoring Costs

You might think laser cleaning is cheap, but there are hidden costs. Look at all the costs, not just the price of the machine.

Here is a table that shows the costs for old cleaning ways and laser cleaning:

| Cost Factor | Traditional Methods | Laser Cleaning |

|---|---|---|

| Consumables Costs | Buy chemicals, abrasives, and solvents often | No extra supplies needed |

| Labor Costs | Takes a lot of time and skilled workers | Less work because of automation |

| Equipment Damage | Tools wear out from rough cleaning | Little damage to machines |

| Downtime | Lose work time while cleaning | Less time lost |

| Waste Management | Pay to get rid of dangerous waste | No extra waste, lower cost |

Laser cleaning saves you money on chemicals and workers. Your machines last longer and you do not stop work as much. You also pay less to get rid of waste.

Note: Always look at the full cost, like fixing and running the machine. This helps you plan your money and avoid surprises.

Underestimating Application Needs

You must pick the right machine for your job. If you do not, you could have problems that slow you down or cost more.

| Consequence | Explanation |

|---|---|

| Performance Degradation | Not thinking about your workspace can make the machine work worse. |

| Safety Hazards | Missing important needs can make things unsafe for workers. |

| Increased Operational Costs | Not planning can mean more fixing and higher costs later. |

If you do not think about your space or what you need to clean, the machine might not work well. You could have safety problems or pay more for repairs.

⚠️ Always check your job needs before you buy. Make sure the machine fits your work, your space, and your safety rules.

You can stop these mistakes by planning and learning about your choices. This helps you get good results and keep your money safe.

Future Trends

Continuous Laser Innovations

Continuous laser cleaning machines are getting new features. These features make cleaning easier and safer. Most machines do not need chemicals or abrasives now. This helps keep the environment safe. For example, the LC-CLEAN CW 1500W cleans rust, paint, and grease with high precision. You can change the speed and beam size using built-in controls. You can also pick how the machine works.

Manufacturers have made machines more powerful. The Wattsan CW 6000W uses a 6000W laser. This is twice as strong as older models. It cleans big areas very fast. It has safety features like two-step activation and a grip sensor. These features help stop accidents. You can pick different laser sources, such as Raycus or JPT. The CW 6000 has a wide beam width of 500 mm. You can clean car chassis and factory walls easily.

- No chemicals or abrasives needed

- Controls let you change speed and beam size

- Strong lasers clean faster

- Safety features protect users

- You can pick your laser source

Pulsed Laser Advances

Pulsed laser cleaning machines have improved a lot. You can save up to 70% energy compared to old cleaning ways. High pulse rates, with over 1000 pulses each second, help you finish jobs faster. AI control systems change settings in real time. This gives you the best results for every surface.

New pulsed lasers give more energy but do not hurt fragile materials. Smart technology and automation make cleaning easier and more accurate. Over 70% of early users say they spend less time on manual cleaning. You will see less downtime and better work speed. Real-time monitoring lets you check how well the machine works.

- Save up to 70% energy

- Fast cleaning with high pulse rates

- AI controls make smart changes

- Stronger pulses for tough jobs

- Automation improves performance

- Real-time monitoring helps you track cleaning

Automation Integration

Automation is changing how laser cleaning machines work. New systems fit into automated production lines. You can clean parts with little human help. This makes work faster and keeps things running well.

Here is a table that shows how automation helps:

| Automation Feature | Description |

|---|---|

| Efficiency | Handles lots of cleaning tasks and boosts productivity. |

| Safety | Less operator work means lower risk. |

| Precision | Gets cleaning quality that manual work cannot match. |

You can set up continuous laser cleaning machine and pulse laser cleaning machine systems with robots and smart controls. This gives you faster, safer, and more exact cleaning every day.

Tip: Automation lets you do other important jobs while your laser cleaning machines handle the hard cleaning.

You have learned how continuous and pulsed laser cleaning machines are different. Continuous machines work quickly on big areas. Pulsed machines are good for fragile surfaces. Use the checklist to help you choose the best machine for your job.

- Look at what materials you need to clean

- Think about how big your job is

- Choose if you want speed or careful cleaning

After that, ask a supplier for help or see a demo. Choosing the right machine gives you better cleaning and keeps your things safe.

FAQ

What materials can you clean with a laser cleaning machine?

You can clean metals like steel and aluminum. Copper is also a metal you can clean. Non-metals like plastics and ceramics can be cleaned too. Stone is another non-metal you can clean. Always check if the material is sensitive before you start.

Is laser cleaning safe for delicate surfaces?

Pulse laser cleaning machines keep delicate surfaces safe. You can clean antiques and artwork with them. Electronics can be cleaned without damage. Always test on a small spot first.

How fast can you clean with a continuous laser cleaning machine?

You can clean big surfaces very fast. Most people finish large jobs in minutes. The steady beam covers wide areas quicker than by hand.

Do you need special training to use a laser cleaning machine?

You should learn basic safety rules first. You also need to know how to use the controls. Most suppliers teach you how to use the machine. After a short lesson, you can use it safely.

What safety gear do you need when using laser cleaning machines?

You must wear laser safety goggles every time. You should also use gloves and protective clothes. Always follow the safety steps from the manufacturer.

Can you use laser cleaning machines for outdoor jobs?

You can use portable laser cleaning machines outside. Air-cooled models work well outdoors. Make sure you have a steady power source.

How do you choose between continuous and pulsed laser cleaning machines?

You should think about your material and job size. You also need to know if you want precision. Continuous lasers are best for speed and big areas. Pulsed lasers are better for careful or detailed cleaning.

See also

The advantages of laser rust removal technology in ship maintenance

The advantages of laser cleaning in the automotive industry

What Factors Affect the Lifespan of Fiber Laser Cleaning Machines

How to Protect Yourself When Operating a Laser Cleaning Machine