You need the maintenance of laser welding equipment to ensure it works well and delivers good results. Taking care of it often helps prevent sudden problems and keeps your workspace safe. Many people forget to clean inside the machine every 8 hours or skip checking the gas circuits. If you remember to clean the nozzles, check the gas outlets, and change old parts, your equipment will last longer, and you can avoid expensive fixes.

- Cleaning often gets rid of dust and dirt that can cause problems.

- Checking parts helps you find issues before they get worse.

- Changing used-up parts on time stops other parts from getting damaged.

- Updating software and calibrating keeps your machine working right.

When you prioritize the maintenance of laser welding equipment, you protect your money and achieve good results every time.

Key Takeaways

- Clean your laser welding equipment often to stop dust and dirt from building up. This helps your machine work well and makes sure your welds are good.

- Check your equipment every day for any signs of damage or things wearing out. Finding problems early can help you avoid expensive repairs and lost time.

- Always look at coolant levels and check for leaks in the cooling system. Taking care of the coolant stops the machine from getting too hot and helps it last longer.

- Write down all the times you do maintenance or repairs. This lets you keep track of your equipment’s condition and plan for what it needs later.

- Make sure you get the latest software updates. Updates make your equipment work better and fix problems, so it stays safe and works well.

Maintenance of Laser Welding Equipment

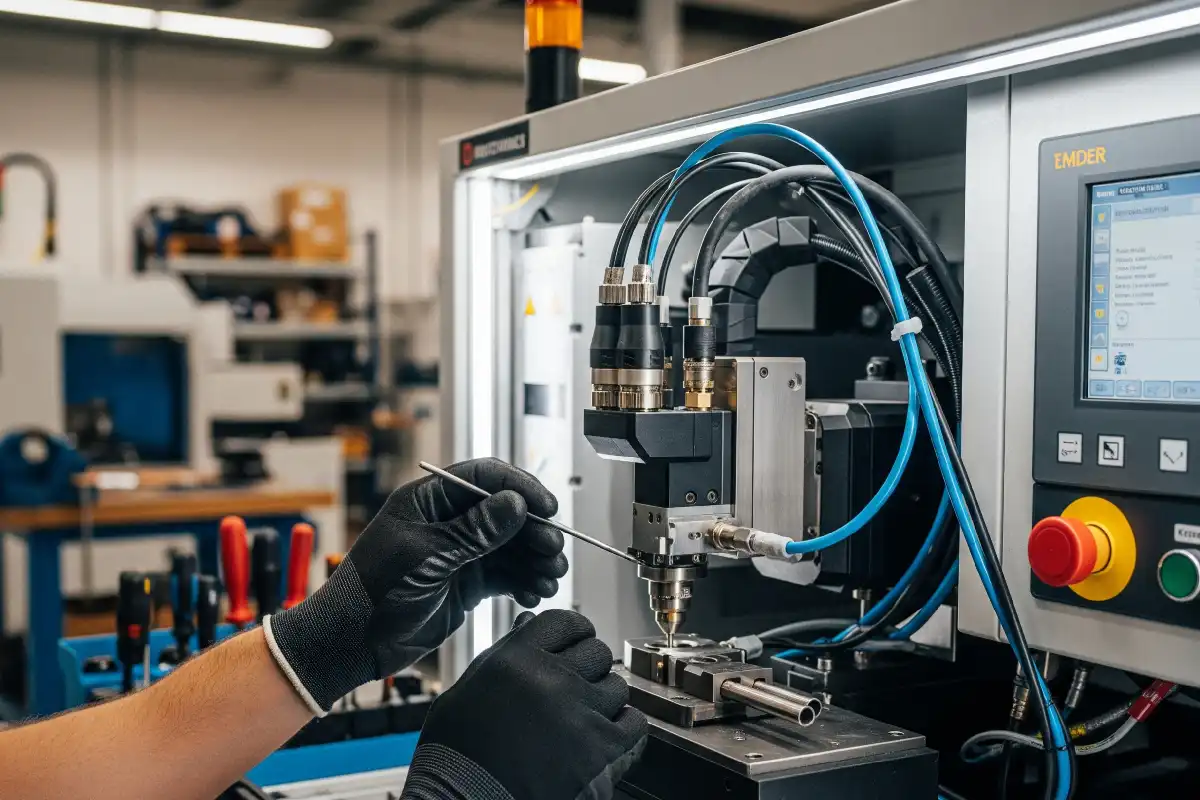

Visual Inspection

You need to check your laser welding equipment every day before you start working. Look at the protective lens for dust, oil stains, splashes, or burn marks. Check the copper nozzle for blockages or signs of wear. Every week, clean the air inlet and outlet filters to remove dust. Inspect all cables for damage or wear.

Tip: Place a clean white sheet of paper about 200–300 mm from the nozzle. Watch the red light spot on the paper. If you see a regular shape, uniform brightness, and sharp edges, your lens is clean. If you notice black spots, dark areas, or odd shadows, your lens may be contaminated.

Make sure the surface of the material is clean before welding. Use acetone to remove grease and oil. Scrub off rust, scale, or coatings with a wire brush. Confirm that the material is dry. Always check critical parts for damage or misalignment. These steps help you catch problems early and keep your equipment working well.

Cleaning Gas Outlet Tubes

Gas outlet tubes play a big role in the maintenance of laser welding equipment. Moisture can enter the welding process from humidity, dirty gas lines, or poorly stored parts. When moisture gets inside, it can cause gas pockets, cracks, and weak welds. Too much hydrogen can make the weld brittle and cause sudden failure.

- Porosity and gas pockets can form inside the weld.

- Cracks may appear long after welding, which can be dangerous.

- Welded joints can become stiff and break easily.

- The weld may look bad and have weak spots.

Clean the gas outlet tubes often to prevent these problems. Make sure the tubes are dry and free from dirt. This keeps the shielding gas stable and helps you get strong, clean welds.

Cleaning External Surfaces

You need to keep the outside of your laser welding equipment clean. Dust and dirt can build up on the machine and in your workspace. Wipe down the surfaces with a soft cloth. Clean the area around the equipment to make sure air can flow freely. Good ventilation helps prevent overheating and keeps the equipment safe.

Note: A clean workspace makes it easier to spot leaks, damage, or other issues. It also helps you work safely and keeps your equipment in good shape.

Regular cleaning is a key part of the maintenance of laser welding equipment. When you keep everything clean, you avoid problems and help your equipment last longer.

Cooling System Care

Taking care of your cooling system is very important. It helps your laser welding equipment work well and last longer. The cooling system stops the machine from getting too hot. If you do not take care of it, your machine can break. Your welds may not look good.

Check Coolant Levels

Coolant takes away heat from the machine. This keeps the temperature safe. You need to look at the coolant before every shift. If there is not enough coolant, the machine can get too hot and stop.

Tip: Always use the coolant the maker says to use. The wrong coolant can block or damage the system.

If you use your laser welding equipment with low coolant, you can have problems:

- The laser may not be as strong, so welds are weak.

- Welds can have holes, cracks, or not go deep enough.

- The machine may break more often and cost more to fix.

Inspect for Leaks

Leaks in the cooling system can make coolant go away. This can make the machine too hot. You should look for leaks often. There are many ways to find leaks:

| Method Type | Description |

|---|---|

| Indirect Leak Detection | Watch how the system works to find leaks without touching coolant. |

| Differential Pressure Monitoring | Check for pressure drops to see if there are leaks. |

| Coolant Reservoir Level Sensors | Look for changes in fluid levels to spot slow leaks. |

| Temperature and Flow Rate Analysis | Watch for changes in temperature or flow. |

| Direct Leak Detection | Look at the coolant to see if there are leaks. |

| Leak Detection Cables and Ropes | Use special cables that sense leaks when they get wet. |

| Optical and Conductivity Sensors | Use special tools to find liquid where it should not be. |

| Acoustic Emission Leak Detection | Listen for sounds that mean there is a leak. |

Drain Water Cooler in Winter

Cold weather can freeze water in the cooling system. Frozen water can break pipes and hurt your machine. You should empty the water cooler and turn off the machine before winter.

- Turn off the power to the laser and chiller.

- Open the drain and let the water come out.

- Use air to blow out any water left inside.

- Close the water inlets and outlets with rubber plugs to keep out dust.

Note: Clean the water tank and filters after you drain them. This stops dirt from building up when you use the machine again.

Calibration and Alignment

Laser Alignment

It is important to check the alignment often. Good alignment helps you make strong welds. If the laser beam misses the spot, welds can look uneven. Weak joints can happen if the laser is not lined up. Watch for odd weld shapes or results that do not match. Keeping the laser aligned helps you avoid mistakes and saves time.

Tip: Try using a test piece before starting a new project. This lets you find problems early.

Routine Calibration

Routine calibration helps your machine work well. You need to set the laser power, focus, and alignment right. Calibration stops defects and makes welds better. Follow a schedule based on how much you use your equipment. The materials you use also matter.

| Calibration Frequency | Conditions Affecting Frequency |

|---|---|

| Once per year | Standard equipment use |

| Biannual or quarterly | Constant use |

| More frequent | Varied or specialized materials |

| More rigorous | Industry-specific regulations |

| Prompted by | Discrepancies in outputs |

Calibrating often keeps weld quality high. You can stop problems like weak welds, holes, or cracks. This also helps your equipment last longer.

- Calibration makes sure your machine gives the right laser power and focus.

- You get fewer defects and better reliability.

- You keep your settings right for every job.

Record Keeping

You should keep good records of all maintenance and calibration. Write down when you change the lens protector, focus lens, or nozzle. Record when you clean the laser gun and gas outlet tube. Track when you inspect the lens protector and check the laser cooler. Good records help you see patterns and plan for future care.

- Change lens protector

- Change the focus lens

- Clean the laser and gas outlet tube

- Change the nozzles

- Check the laser cooler

- Clean the laser gun

- Inspect the lens protector often

Keeping clear records helps you not miss steps and keeps your equipment working well.

Gas Supply Checks

Inspect Gas Lines

You need to check your gas lines often to keep your laser welding equipment working well. Gas lines carry shielding gas to the weld area. Problems in these lines can hurt weld quality and safety. When you inspect gas lines, look for these common issues:

- Improper shielding gas selection can cause unwanted chemical reactions.

- Low flow rates let air mix in, which leads to contamination.

- Moisture or dirt in the gas supply can weaken your welds.

If you find any of these problems, fix them right away. Clean or replace dirty lines. Make sure you use the right gas for your job. Always keep your gas lines dry and free from leaks.

Monitor Pressure and Flow

You must watch the pressure and flow of your shielding gas. If the flow is too low, your welds can get weak or porous. If the pressure is too high, you waste gas and may disturb the weld. Different gases need different flow rates. Here is a quick guide:

| Gas Type | Minimum Flow Rate (CFH) | Adjusted Flow Rate (CFH) |

|---|---|---|

| General Shielding | 32 | N/A |

| Galvanized Steel | N/A | 60 |

You may use gases like argon, helium, nitrogen, or carbon dioxide. Always check your gauges before you start. Adjust the flow to match your material and job needs.

Tip: If you see bubbles or hear hissing, check for leaks right away.

Replace Cylinders Safely

When you need to change a gas cylinder, follow safety steps every time. Gas cylinders can be dangerous if you do not handle them right. Here are some important rules:

| Safety Protocols | Description |

|---|---|

| Proper labeling and handling | Make sure each cylinder is labeled and you know what gas it holds. |

| Monitor pressure regulators | Check that regulators and gauges work and show the right levels. |

| Store cylinders upright | Keep cylinders standing up in a dry, open area. Inspect them often. |

- Never crush welding wires. This can cause leaks.

- Do not put cylinders in the sun or near heat.

- Stand to the side when you open the valve.

By following these steps, you keep yourself and your workspace safe. Good gas supply checks help you get strong, clean welds every time.

Software Updates

Check for Updates

You should check for software updates often. Updates help your laser welding equipment work better. They fix problems and add new features. Companies make updates to improve safety and fix bugs. You can find updates on the manufacturer’s website or in the user manual.

- Watch for update alerts on your machine’s screen.

- Go to the official website every month.

- Sign up for emails from the manufacturer.

Tip: Put a reminder on your phone or calendar. This helps you remember to check for updates.

If you skip updates, your equipment may not work well. You could miss important improvements. Always update your machine to keep it safe and working right.

Install and Backup

Before you install updates, back up your settings and data. This keeps your work safe if something goes wrong. Use a USB drive or cloud storage to save your files.

Steps to Install and Backup:

- Save your settings and job files.

- Read the update instructions from the manufacturer.

- Install the update the way the maker says.

- Restart your machine when the update is done.

- Check that your settings and files are still there.

| Step | Why It Matters |

|---|---|

| Backup data | Keeps your important files safe |

| Follow instructions | Stops mistakes during installation |

| Restart equipment | Makes sure updates work |

Note: If you have problems, call technical support. They can help you fix update issues.

Updating your software helps your laser welding equipment work better. You get better performance, fewer mistakes, and your machine lasts longer.

Operator Training

Regular Training

You need regular training to use laser welding equipment safely. Training teaches you how the machine works. It helps you avoid mistakes. When you know the basics, you can spot problems early. This keeps you and others safe at work.

Here are some important things to learn in training:

- Laser fundamentals: Learn about wavelengths and beam properties. Know how lasers are put into groups.

- Material interactions: Study how metals and alloys act when you weld them with a laser.

- Biological effects: Learn the risks to your eyes and skin from laser exposure.

- Laser safety eyewear (LPE): Find out how to pick and care for safety glasses.

- Protective clothing: Wear flame-resistant clothes and other PPE.

- Work practices: Set up your workspace safely. Align the beam and keep things neat.

- Emergency procedures: Learn what to do if there is an accident or someone gets hurt.

Tip: Go over your training every few months. New machines or materials may need new skills.

Safety Protocols

You must follow safety rules every time you use laser welding equipment. These rules keep you and your coworkers safe. Good safety habits help your equipment last longer.

| Safety Protocols | Description |

|---|---|

| Operator Training | Get good training on equipment and safety steps. |

| Personal Protective Equipment | Always wear laser safety glasses and flame-resistant clothes. |

| Environmental Controls | Work in a space with good air flow to avoid bad fumes. |

| Emergency Response Procedures | Know what to do if there is a fire, power loss, or injury. |

| Designated Laser-Controlled Area | Use a closed area to stop accidental laser exposure. |

| Proper Signage | Put up clear signs to warn about laser dangers. |

Safety is not just a rule. It is a habit that keeps you safe every day. Always check your gear and workspace before you start welding.

Professional Servicing

Schedule Service

You should plan for regular professional servicing. Certified technicians can find problems you might not see. They use special tools and follow strict steps. This keeps your machine safe and working well.

- Get professional inspections once or twice a year. This is what most makers suggest.

- Certified technicians can spot small problems early.

- Regular servicing helps you avoid sudden breakdowns and expensive repairs.

Tip: Write your next service date on your calendar. Set reminders so you do not forget a checkup.

Professional servicing includes things you cannot do alone. Technicians check the laser’s power and clean inside the machine. They test safety systems and update firmware. They also change old parts. After each visit, you get a report. The report shows what was checked and what needs fixing.

Maintain Records

You should keep clear records of every professional service. Good records help you track your equipment’s health over time. They also show you follow safety rules and maker guidelines.

| What to Record | Why It Matters |

|---|---|

| Service dates | Helps you plan future maintenance |

| Technician’s findings | Shows what was checked or repaired |

| Parts replaced | Tracks wear and helps with budgeting |

| Recommendations | Guides your next steps |

- Keep your records safe in a binder or digital folder.

- Look at your records before each service. This helps you find patterns or repeat problems.

Keeping good records makes it easier to get warranty help. It also helps you show you care for your equipment.

Professional servicing and good record-keeping keep your laser welding equipment working well. You save money, avoid downtime, and stay safe every day.

Taking care of your laser welding equipment helps you in many ways. Your machine works better and breaks down less. You stay safe at work and your welds stay strong. If you check your equipment often, you can find problems early. This helps you avoid spending a lot of money on repairs.

- Following safety steps makes accidents less likely.

- Caring for your equipment helps it last longer.

- Good care keeps welds strong and stops delays.

Make a plan to check your equipment often. Pay attention and keep your equipment safe every day.

FAQ

How often should you clean the lens and nozzle?

You should clean the lens and nozzle every day before you start welding. This keeps your welds strong and your equipment safe.

What should you do if you find a coolant leak?

Turn off your machine right away. Check the hoses and connections for damage. Fix or replace any broken parts before using the equipment again.

Can you use tap water in the cooling system?

No, you should not use tap water. Tap water can cause rust and blockages. Always use the coolant recommended by the manufacturer.

Why is record keeping important for maintenance?

Record keeping helps you track what you have done. You can spot patterns and plan future care. Good records also help with warranty claims.

How to Match Laser Welding Machine Power to Your Needs

Step-by-Step Guide to Selecting the Right Laser Welding Machine

How to Improve Manufacturing Speed with Laser Welding

The application advantages of laser welding in thin material welding