You will see that laser welding is usually stronger than MIG welding for thin and medium materials. This method makes deep and narrow welds because it uses a strong, focused beam. These welds are often as strong as the material itself. Weld strength depends on many things like how thick the material is, how exact the work is, and what it is used for. The table below lists the most important things that affect how strong your welds are:

| Factor | Description |

|---|---|

| Laser Power | Controls how deep the weld goes and how much heat is used |

| Welding Speed | Changes how much heat is given and how deep the weld goes |

| Focus Position | Decides how well the laser beam works |

| Material Type | Each material acts in its own way |

| Shielding Gas | Keeps the melted metal safe from getting dirty |

| Pulse Duration | Changes how much heat is used and how deep the weld goes |

Key Takeaways

- Laser welding makes stronger joints for thin and medium materials. It uses focused energy and has a small heat-affected zone.

- MIG welding works well for thick metals and hard jobs. It makes more heat, which can cause the metal to bend.

- You should pick the right welding method for your material and project. Laser welding is good for careful work. MIG welding is better for big, tough jobs.

- The skill of the person welding matters a lot for weld quality. Laser welding needs special training. MIG welding is easier to learn.

- Always clean the metal before you start welding. This helps make strong joints. It is very important for MIG welding. Cleaning stops dirt and weak welds.

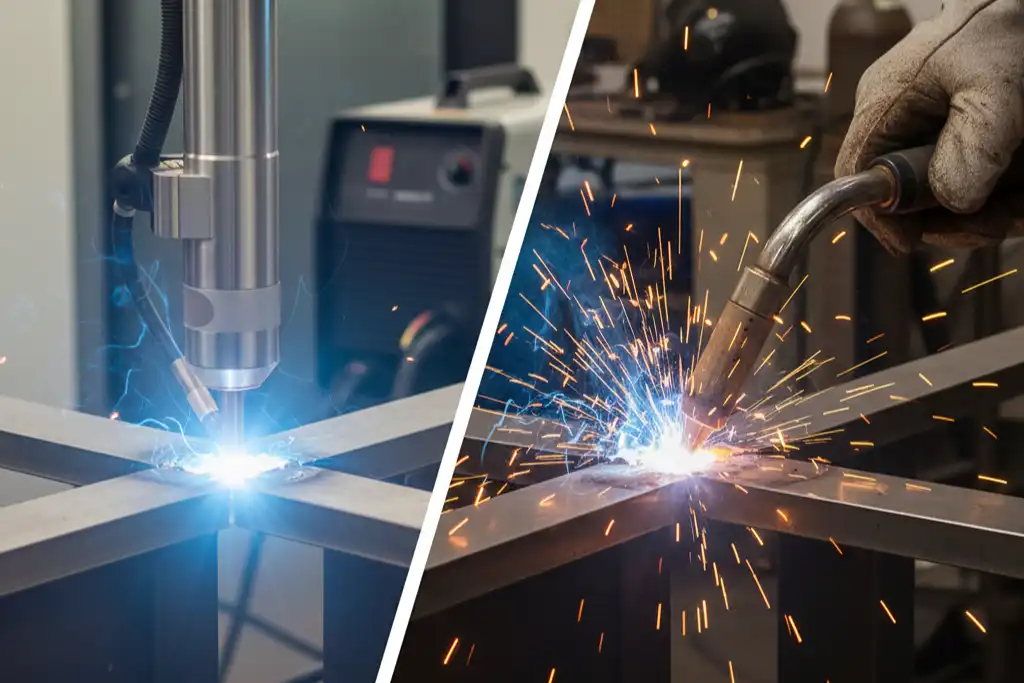

Weld Strength Comparison

Laser Welding Strength

Laser welding makes joints that are strong and exact. The laser’s focused energy makes a deep, thin weld. This helps the joint keep up to 90% of the base metal’s strength. The small heat-affected zone keeps the metal from bending or changing. You get less bending and better quality. Laser welding works best for thin and medium metals like stainless steel, carbon steel, and aluminum. The table below shows how much thickness different laser welder powers can handle for each material:

| Laser Welder Power | Material Type | Maximum Thickness |

|---|---|---|

| 1 kW | Stainless Steel | 3mm |

| Carbon Steel | 3mm | |

| Aluminum | 3mm | |

| 1.5 kW | Stainless Steel | 5mm |

| Carbon Steel | 4mm | |

| Aluminum | 4mm | |

| 2 kW | Stainless Steel | 6mm |

| Carbon Steel | 5mm | |

| Aluminum | 5mm | |

| 3 kW | Stainless Steel | 8mm |

| Carbon Steel | 8mm | |

| Aluminum | 6mm |

Laser welding helps you save time and waste less material. You also get a weld that is stronger because of its special structure. The process makes a fusion zone with more tiny changes inside, which makes the joint tougher. Laser welding gives you strong joints and keeps the metal’s good qualities.

- Laser welding makes joints that are stronger and more exact than MIG welding.

- Less heat means less bending and better quality.

- The deep, thin weld makes the joint even stronger.

MIG Welding Strength

MIG welding is good for thick metals and tough jobs. It uses a wire and gas to join the metals. You can get strong welds if you use the right wire and method. For example, a 110,000 PSI wire with 60,000 PSI steel makes a strong joint. But if you use a 60,000 PSI wire with 60,000 PSI steel, the joint may only be 40,000 PSI after it cools down.

| Strength Value | Description |

|---|---|

| 60,000 PSI | Using a 60,000 PSI wire with 60,000 PSI steel can leave tension, so the joint may only be 40,000 PSI. |

| 110,000 PSI | A 110,000 PSI wire with 60,000 PSI steel makes a strong joint. |

| General Strength | MIG welding can be strong if you use the right method and materials. |

The shape of the weld in MIG welding changes how strong it is. The heat-affected zone is medium-sized (2-5 mm), which can cause more bending. You must watch the heat so the joint does not get weak. MIG welding is good for thick joints and works well in tough places.

Fatigue and Durability

You want your welds to last when used many times. Laser welding is better at handling repeated stress and keeps its shape better than MIG welding. It uses faster welding and less heat, so parts stay strong and last longer. The heat-affected zone is small, so the metal keeps its strength.

MIG welding makes strong welds for hard work, but the bigger heat-affected zone and more heat can cause more bending and shorter life. You may need to clean up more because MIG welding makes more mess.

| Welding Method | Advantages | Disadvantages |

|---|---|---|

| Laser Welding | Very exact, less bending, less waste, good for thin and strong metals | Costs more at first, not for every job |

| MIG Welding | Cheaper, can be used in many ways, works in tough places | Makes more mess, bigger heat zone, needs more cleaning |

- Laser welding keeps the heat zone small, so there is less risk of bending.

- MIG welding is strong for hard jobs but makes more heat, which can bend the metal.

If you want welds that last and do not break easily, laser welding is better for thin and medium metals. MIG welding is still a good pick for thick joints and tough jobs.

Factors Affecting Strength

Material Type

You need to think about the type of metal you want to weld. Different metals react in their own way to heat and welding. Laser welding gives you a smaller and more even heat-affected zone. This helps keep the metal strong and stops it from getting weak or full of holes. MIG welding uses more heat, which can make the metal bend or lose strength, especially in thin pieces. If you want to join two different metals, laser welding works better because it uses less heat and keeps the metals from mixing too much. MIG welding has a hard time with different metals because they melt at different rates.

Here is a quick look at how each method handles different materials:

| Welding Method | Material Compatibility Issues | Strengths | Weaknesses |

|---|---|---|---|

| Laser Welding | Can join various materials, including dissimilar ones | Flexible, low heat prevents warping | Not ideal for thick materials |

| MIG Welding | Struggles with joining different materials | Good for thicker metals, strong welds | Higher heat can cause distortion in thin items |

Tip: Use laser welding for thin or delicate metals. Choose MIG welding for thick metals.

Joint Design

The way you design your joint changes how strong your weld will be. Butt joints and lap joints are common. Butt joints let you fuse two pieces directly, which makes a strong bond, especially with laser welding. For the best results, keep the gap between pieces small. For butt joints, a gap of 3-10% of the thinnest sheet works well. For lap joints, a gap of 5-10% of the top sheet helps avoid problems. If you work with advanced high-strength steel, a tiny gap of 0.1-0.2 mm in overlap joints can stop defects.

- Butt joints give you direct fusion and high strength.

- Lap joints need careful gaps to avoid weak spots.

Welding Parameters

You must set your welding machine the right way to get a strong weld. The power, speed, and gas you use all matter. If you use more power, you get deeper welds. The shape of your joint also matters. If you line up the edges well, your weld will be stronger. Shielding gas keeps the weld clean and stops it from getting weak. The surface of your metal should be clean for the best results. If you hold the pieces steady, you avoid holes and weak spots.

| Parameter | Effect on Strength |

|---|---|

| Laser Power | More power means deeper, stronger welds |

| Joint Geometry | Good alignment gives you better strength |

| Shielding Gas | Keeps weld clean and strong |

| Surface Condition | Clean metal helps energy transfer and weld quality |

| Proper Fixturing | Stops movement and prevents weak welds |

Operator Skill

Your skill as a welder makes a big difference. Laser welding needs more training and practice. If you know what you are doing, you get strong and even welds every time. MIG welding is easier to learn, but the quality can change if you do not pay attention. Good training helps you learn the best ways to weld and keeps you safe. You should keep learning new skills to stay up to date.

| Welding Type | Skill Requirement | Outcome Quality |

|---|---|---|

| Laser Welding | Needs advanced knowledge | High strength and even welds |

| MIG Welding | Easier to learn | Quality can change, more mistakes |

Note: The better your skills, the stronger and more reliable your welds will be.

Strength in Applications

Automotive Use

Laser welding is used a lot in car factories now. It works well for body panels, exhaust systems, and small parts. The welds are strong and clean with less bending. This happens because the heat-affected zone is small. Car parts last longer and look nicer. MIG welding is still important for thick car frames and big parts. Laser welding is best when you need speed and accuracy for thin or medium materials.

- Laser welding is often used for:

- Body panels

- Exhaust systems

- Small, detailed parts

Laser welding gives stronger welds and less bending in these places.

Manufacturing

Many companies pick laser welding for strong and exact joints. You see it in making medical devices, cars, planes, and new energy vehicles. Laser welding joins different materials with high accuracy. There is less heat damage, so sensitive parts stay safe.

| Sector | Benefits |

|---|---|

| Medical Device Manufacturing | Small, clean welds that are safe for the body |

| Automotive | Fast, flexible joints that do not break easily |

| Aerospace | Strong welds and less heat for safety |

| New Energy Vehicles | Quick, no-touch welds for new technology |

Laser-welded joints can be up to 25% stronger than regular welds. This helps products last longer.

Repairs

When fixing metal parts, you want the weld to be strong. MIG welding is good for thick or heavy repairs. It costs less and is easier for big jobs. Laser welding is better for small, careful repairs on thin materials. Some studies say repair welds can be weaker than new welds. You must pick the right method for your repair.

| Aspect | Laser Welding | MIG Welding |

|---|---|---|

| Equipment Cost | Costs more | Costs less |

| Material Type | Best for thin, careful work | Best for thick, heavy work |

| Suitability | Small, exact repairs | Big, heavy repairs |

Laser Welding in Industry

Laser welding is used in many fields like cars, planes, electronics, and medical devices. These jobs need strong, high-quality welds for safety. Laser welding helps join high-strength steel and aluminum alloys. It is also good for parts that must stay clean and exact.

- Makes strong, high-quality welds

- Needed for safety and accuracy

- Used for important parts

If you need fast, exact, and strong welds for thin or medium materials, laser welding is often the best pick. For thick joints or big repairs, MIG welding is still a good choice.

Pros and Cons for Strength

Laser Welding Advantages

You get many benefits when you use laser welding for strong joints. The process creates narrow welds with a deep shape. This means your welds can be stronger than with other methods. Laser welding also keeps most of the base metal’s strength. You can expect over 90% of the original strength to stay in your joint. The small heat zone helps your metal keep its shape and stops it from getting weak.

Here is a table that shows why laser welding makes strong welds:

| Advantage | Description |

|---|---|

| Weld Strength | Narrow welds with a great depth-to-width ratio give you higher strength. |

| Reduced Internal Stresses | Good heat control lowers stress and makes your weld last longer. |

| Lower Heat Input and Smaller HAZ | Less heat means your weld stays strong and does not get damaged. |

| Deep and Narrow Penetration | You get strong, exact joints, which is important for thin metals. |

- Laser welding also improves the inside structure of your weld. This helps your joint resist breaking and bending over time.

Laser Welding Limitations

Laser welding does have some limits. You may find it hard to weld thick materials. The laser cannot always reach deep enough for heavy-duty jobs. You need to line up your parts very well. If you do not, your weld can turn out weak or uneven. You also need special skills to use laser welding machines. If you do not have enough training, your welds may not be strong.

| Limitation | Explanation |

|---|---|

| Limited penetration for thick materials | Laser welding cannot always make deep welds in thick pieces. |

| Operator skill requirement | You need good training to get strong, even welds. |

| Tolerances and fit-up | You must line up your parts very carefully for the best results. |

MIG Welding Advantages

MIG welding gives you strong welds, especially for thick metals. You can use it for many types of jobs. The process works fast and does not cost much. You can weld thick pieces, which is important for building and repairs. MIG welding also makes clean and steady joints. You do not need to spend much time cleaning up after.

- You can weld metals up to 1/2-inch thick or more.

- MIG welding works well for cars, buildings, and repairs.

- The process is quick and helps you finish jobs faster.

MIG Welding Limitations

MIG welding has some downsides for weld strength. You must clean your metal well before you start. Dirt or oil can make your weld weak. Sometimes, the weld does not join the base metal fully. This can make the joint break under stress. If you do not control the process, cracks can form and lower the strength.

| Limitation | Impact on Weld Strength |

|---|---|

| Sensitivity to Contaminants | Dirty metal can cause weak welds. |

| Incomplete Fusion | If the weld does not join well, the joint can break. |

| Cracking | Cracks can form if you do not control the process, making the weld less strong. |

Tip: Always clean your metal and check your settings to get the strongest MIG welds.

You have seen that laser welding gives you stronger joints for thin and medium materials. MIG welding works better for thick metals. Key factors like material type, joint design, welding settings, and your skill shape weld strength. If you need fast, precise, and strong welds for thin parts, choose laser welding. For heavy-duty jobs, MIG welding is a solid choice.

Tip: Think about your project needs and budget before you pick a welding method.

FAQ

Is laser welding always stronger than MIG welding?

Laser welding is usually stronger for thin and medium materials. For thick metals, MIG welding can give you better strength. You should choose the method based on your material and project needs.

Can you use laser welding for thick steel?

Laser welding works best for thin to medium steel. For steel thicker than 8mm, MIG welding is a better choice. You get deeper welds and more strength with MIG on thick pieces.

Does MIG welding make weaker joints on thin metals?

Yes, MIG welding can cause warping or weak spots on thin metals. The higher heat input can bend or damage the metal. Laser welding gives you stronger, cleaner joints for thin materials.

Which welding method is easier to learn?

| Method | Skill Level Needed |

|---|---|

| Laser Welding | Advanced |

| MIG Welding | Beginner |

You will find MIG welding easier to learn. Laser welding needs more training and practice.

Laser Welding Troubleshooting Guide: 10 Defects and Their Fixes

Does laser welding require the use of protective gas?

What You Need to Know About Energy Density in Laser Welding

What Are the Effects of Power Density on Laser Welding Quality