You can use laser cleaning to get rid of many kinds of rust. It works on light rust and heavy rust. You can use it on metals like steel, aluminum, copper, brass, magnesium, lead, and stainless steel. Laser cleaning takes off rust but does not hurt the metal underneath. This makes it safe for parts that are delicate. Laser cleaning is often faster and cleaner than other ways.

| Method | Efficiency Rating (1-10) | Time Required (Hours) | Cost (Per Unit) | Ease of Use |

|---|---|---|---|---|

| Laser Rust Removal | 9 | 1 | $150 | Very Easy |

| Sandblasting | 7 | 3 | $100 | Moderately Easy |

| Wire Brushing | 5 | 2 | $30 | Easy |

| Chemical Rust Remover | 6 | 5 | $40 | Easy |

Laser cleaning costs more at first. But you do not need to buy extra stuff or clean up a lot of waste.

Key Takeaways

- Laser cleaning can take off surface rust, scale rust, and shallow pitting rust from many metals. It does not hurt the metal underneath. This method is quicker and cleaner than old ways to remove rust. It saves time and makes less waste. Laser cleaning works on metals like steel, aluminum, copper, and stainless steel. This makes it useful for many jobs. The first cost may be more, but laser cleaning does not need chemicals. It also needs less cleanup, so it saves money over time. Safety is very important. Only trained workers should use the laser. They must wear the right gear and follow safety rules to keep everyone safe.

How Laser Cleaning Works

Laser Ablation Process

Laser cleaning uses a strong light beam to take off rust from metal. This process is called laser ablation. The laser touches the rust and makes it shake, melt, and turn into gas. The metal under the rust stays clean and safe. You do not need to use chemicals or rough tools. The surface becomes water-repellent and does not rust easily. This happens because the laser makes a thick melted layer and an oxide film. Some machines use water to help remove tough rust. The water makes bubbles that lift off tiny bits of rust. This gives you a cleaner metal and less heat damage.

Tip: Laser cleaning works in many places. You can use it underwater or high up in the air. It is good for many jobs and does not leave waste behind.

Here is a table that shows how laser cleaning works on rust:

| Mechanism | Description |

|---|---|

| Laser Cleaning | High energy makes rust shake, melt, and turn to gas. |

| Surface Treatment | Makes a thick melted layer and oxide film to protect. |

| Water-Supplied Method | Bubbles help take off tough rust and lower heat. |

| Economic Benefits | Saves money by using only electricity, no extra stuff. |

| Environmental Impact | Makes less waste and keeps workers safe. |

| Application Versatility | Works in many places, even underwater or high up. |

Types of Lasers for Rust Removal

There are different lasers you can use for rust removal. Fiber lasers are used the most. They use a 1064 nm wavelength and work great on rust, oil, and oxides. CO₂ lasers have a longer wavelength and are better for thick metal, but they do not clean rust as well. Nd:YAG lasers also use 1064 nm and clean many things, but they need more care.

Here is a table that compares laser types:

| Laser Type | Wavelength | Absorption by Rust | Efficiency | Common Use |

|---|---|---|---|---|

| Fiber | 1064 nm | High | Excellent | Rust, oil, oxide |

| CO₂ | 10.6 μm | Low | Poor | Paint, plastics |

| Nd:YAG | 1064 nm | Moderate | Good | Multi-material cleaning |

You can find pulsed laser cleaning machines with power from 100W to 500W. Continuous wave lasers can go up to 3000W for bigger jobs. Fiber lasers give the best mix of power and efficiency for rust removal.

Note: Keep the laser source, optics, and scanner head clean. If you take care of your machine, it will work better and last longer.

Laser cleaning keeps getting better. New machines are smaller and smarter. Stronger lasers clean hard rust faster. You save money and help the earth because you do not use chemicals.

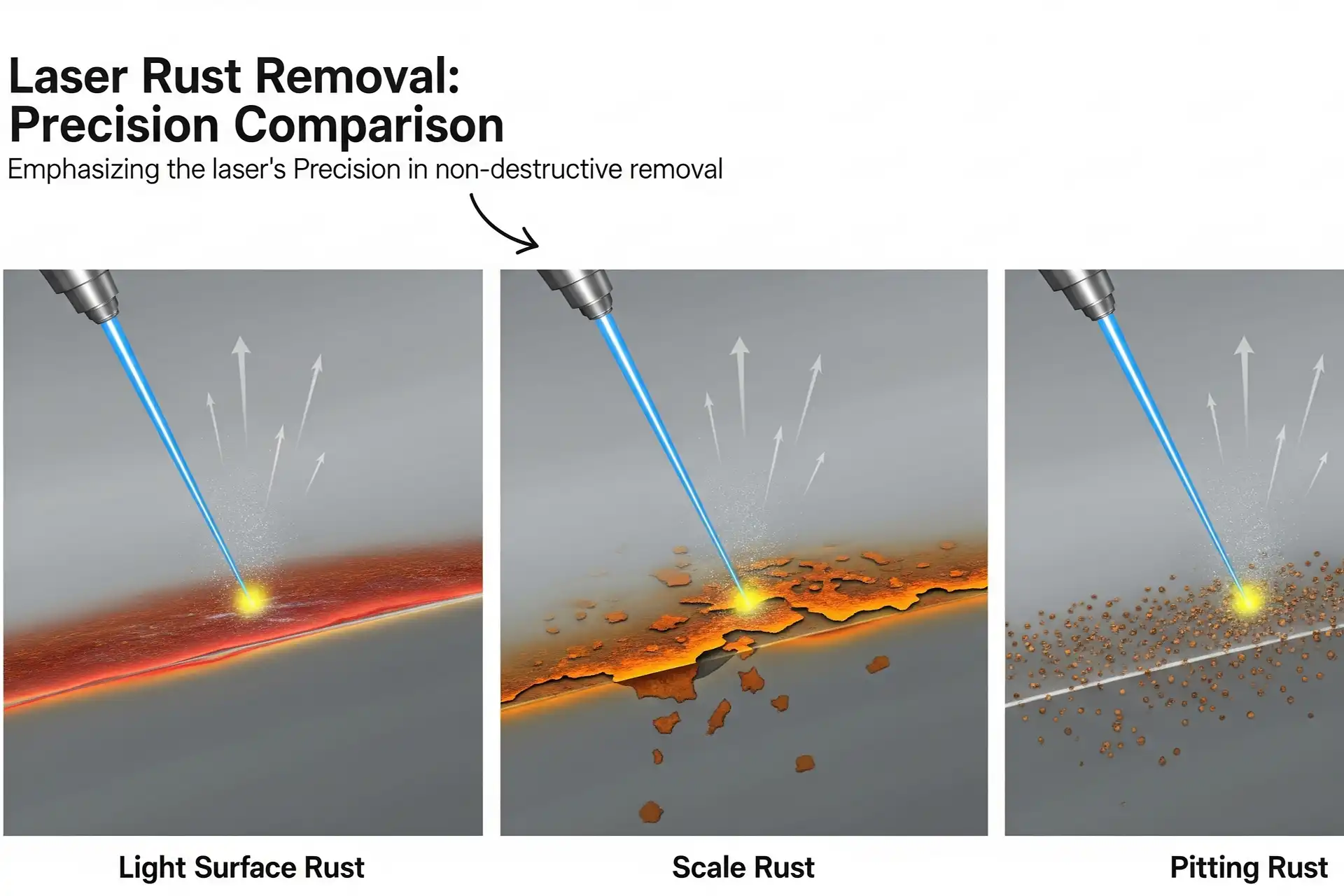

Types of Rust Removable by Laser Cleaning

Surface Rust

Surface rust is the first kind of rust on metal. It looks like a thin, reddish-brown layer. Laser cleaning works great for this rust. You can take off surface rust fast and safely. The metal under the rust does not get hurt. The finish is smooth and clean.

Here is a table that shows how laser cleaning changes the surface:

| Condition | Rust Layer Thickness (micrometers) | Surface Smoothness | Rust Spots Visibility |

|---|---|---|---|

| Before cleaning | 200 | High | Visible |

| After cleaning | <10 | Significantly Improved | Completely Removed |

Tip: Laser cleaning works for tools, car parts, and machines with surface rust. The cleaned items look almost new.

Scale Rust

Scale rust is thicker and harder than surface rust. It forms when rust builds up for a long time. You see rough patches or flakes on the metal. Laser cleaning can take off scale rust from many metals. You do not need chemicals or sandblasting.

Here is a table that shows how laser cleaning works on different metals with scale rust:

| Metal Type | Effectiveness of Laser Cleaning |

|---|---|

| Steel | Works well for rust and scale |

| Stainless Steel | Very good, makes the surface better without damage |

| Aluminum | Cleans rust or oxide layers without touching the metal |

- Laser cleaning is safe for many metals.

- It keeps the metal strong and undamaged.

- It removes rust, oil, and grime well.

Laser cleaning is good for the environment. You do not use harsh chemicals. You make less waste. This helps the planet.

Pitting Rust

Pitting rust is the worst kind. It makes small holes or pits in metal. Laser cleaning can take off rust from the surface and shallow pits. It may not work well for deep pits.

- High starting cost

- Some limits for surfaces and materials

- More steps needed to use

- Slower cleaning for deep rust

You may need extra steps for deep pitting rust. Laser cleaning works best for shallow pits. You can clean the area and stop rust from spreading.

Note: Laser cleaning costs a lot at first and may need special settings for thick coatings. It can be slower for heavy pitting rust.

Summary Table: What Types of Rust Can Be Removed

| Rust Type | Laser Cleaning Effectiveness | Best Use Cases | Limitations |

|---|---|---|---|

| Surface Rust | Excellent | Tools, car parts, machinery | None for thin layers |

| Scale Rust | Very Good | Pipes, industrial parts | May need more passes |

| Pitting Rust | Moderate | Shallow pits, prevention | Not ideal for deep pits |

Laser cleaning is a safe and clean way to remove rust. You can use it for many jobs and metals. It works best for surface and scale rust. You need extra care for pitting rust.

Metals Suitable for Laser Cleaning

Common Metals (Steel, Aluminum, Copper, Brass)

You can use laser cleaning on many common metals. Each metal reacts in a different way, so you need to know what to expect.

- Steel is one of the best metals for this method. You can remove rust and corrosion from carbon steel and stainless steel without damaging the surface.

- Aluminum works well, but it reflects a lot of laser energy. You need to adjust the laser settings to clean it safely.

- Copper and brass also reflect laser light. For copper, you need a higher energy level to break the bonds in the rust or oxide layer. Brass can be cleaned, but you must use the right settings to avoid melting the surface.

Laser cleaning removes coatings, oxides, and paint from these metals. You do not need chemicals or abrasive tools. This method keeps the metal strong and does not change its shape.

Note: You must use the correct laser settings for each metal. If you use too much energy, you can damage the surface. If you use too little, you may not remove all the rust.

Other Metals (Magnesium, Lead, Stainless Steel)

You can also use this method on other metals.

- Magnesium is light and soft. You can clean it, but you must use low energy to avoid burning the surface.

- Lead is heavy and soft. You can remove surface rust, but you need to control the heat to keep the metal safe.

- Stainless steel is strong and resists rust. You can use laser cleaning to remove stains, oxides, and even some coatings without harming the metal.

Some metals may change a little after cleaning. The surface can become smoother or rougher. The way the metal wears down or resists rust can also change. If you clean moving parts, the friction may change. You should check the metal after cleaning to make sure it still works well.

Cleaning the right metals with the right settings helps you keep your parts strong and safe for a long time.

Limitations and Safety

When Laser Cleaning May Not Work

Laser cleaning does not work for every job. Some rust and surfaces are hard to clean. If rust makes deep pits, the laser cannot reach the bottom. Laser cleaning works best for surface and scale rust. Deep holes can stay after cleaning. Non-metal things like plastic or painted wood do not react to the laser. You cannot use laser cleaning on these materials. Some coatings or layers bounce the laser beam away. This makes cleaning weaker. Handheld machines can have worn parts or dirty optics. These problems make the laser less strong and cleaning less good.

Common problems you may see are:

- Dirty optics can make the laser weaker by 20%.

- Blocked cooling can make the machine too hot and break.

- Old software or worn parts can make the laser less exact.

- Bad fume removal can be unsafe for health.

Tip: Check and fix your machine often to stop most problems.

Safety and Base Material Protection

You must follow safety rules when using laser cleaning. Only trained people should use these machines. You need to lock the laser system with keys or passwords. Always keep the laser beam inside a safe area. Use tools to remove fumes and waste from your workspace.

Operators must wear special glasses for the laser’s wavelength. Make sure the glasses meet EN 207 rules. You should check and change safety gear often. Training like Laser Safety Officer (LSO) and maker lessons help you stay safe. Follow OSHA, ANSI Z136.1, and local safety rules.

- Find dangers and check risks before you start.

- Write down all safety steps and risk checks.

- Use only approved safety gear and follow all rules.

Safety rules keep you safe and your work area secure. Good training and regular checks help stop accidents and protect the base metal.

Laser cleaning can take off surface rust, scale rust, and shallow pitting rust. It works on metals like steel, aluminum, copper, brass, magnesium, lead, and stainless steel. You get quick cleaning that targets only the rust. You do not need chemicals, so there is little waste. You can use laser cleaning in many places. It helps metal parts last longer.

| Key Benefits | Key Limitations |

|---|---|

| Fast and precise | High equipment cost |

| No chemicals needed | Needs trained operators |

| Minimal waste | Not for all rust or surfaces |

If your metal has very bad rust, ask an expert for help. Professionals know how to pick the right laser. They set safe power levels. They make sure your metal gets the best cleaning.

FAQ

What types of surfaces can you clean with laser rust removal?

You can clean metal surfaces like steel, aluminum, copper, brass, magnesium, lead, and stainless steel. Laser cleaning works best on hard, solid metals. It does not work on plastic, wood, or painted surfaces.

What safety gear do you need for laser cleaning?

You need special laser safety glasses that match the laser’s wavelength. You should also wear gloves and use fume extraction tools. Always follow safety rules and training.

What happens to the rust after laser cleaning?

The laser turns rust into tiny dust and gas. You can remove the dust with a vacuum or fume extractor. The process leaves almost no waste.

What are the main limits of laser rust removal?

Laser cleaning does not work well for deep pits or non-metal surfaces. You may need extra steps for thick coatings. The machine costs more than other cleaning tools.

See also

How Laser Rust Removal Technology Protects Critical Aircraft Components

How many hours can a laser cleaning machine work nonstop

Fiber vs Solid-State Laser Cleaning Machines: Which Performs Better

How Quickly Can a Laser Cleaning Machine Work