Laser cutting machine radiation can be dangerous if you do not follow safety rules. You might face risks like burns or eye injuries. You need to know how this radiation works and what steps can keep you safe. If you work with or near these machines, you should always stay alert and use the right protection.

Key Takeaways

- Laser cutting machine radiation can hurt you badly. It can cause burns and eye injuries. Always put safety first.

- Lasers give off invisible infrared and ultraviolet light. These lights can hurt you even if you do not see them. Wear protective gear to stay safe.

- Some people believe myths about laser safety. These myths can make things dangerous. Always check safety facts before using machines.

- Anyone near laser cutting machines can get hurt. People with health problems are at higher risk. Stay careful and use the right safety equipment.

- Follow all safety rules. Wear laser safety glasses and protective clothes to stop injuries.

- Good airflow is very important when using laser cutting machines. Make sure your workspace has fresh air. This helps you avoid breathing in bad fumes.

- Learn about the different classes of lasers. Higher class lasers are more dangerous. They need stronger safety steps.

- Training and knowing about laser safety help a lot. They lower the chance of accidents and injuries.

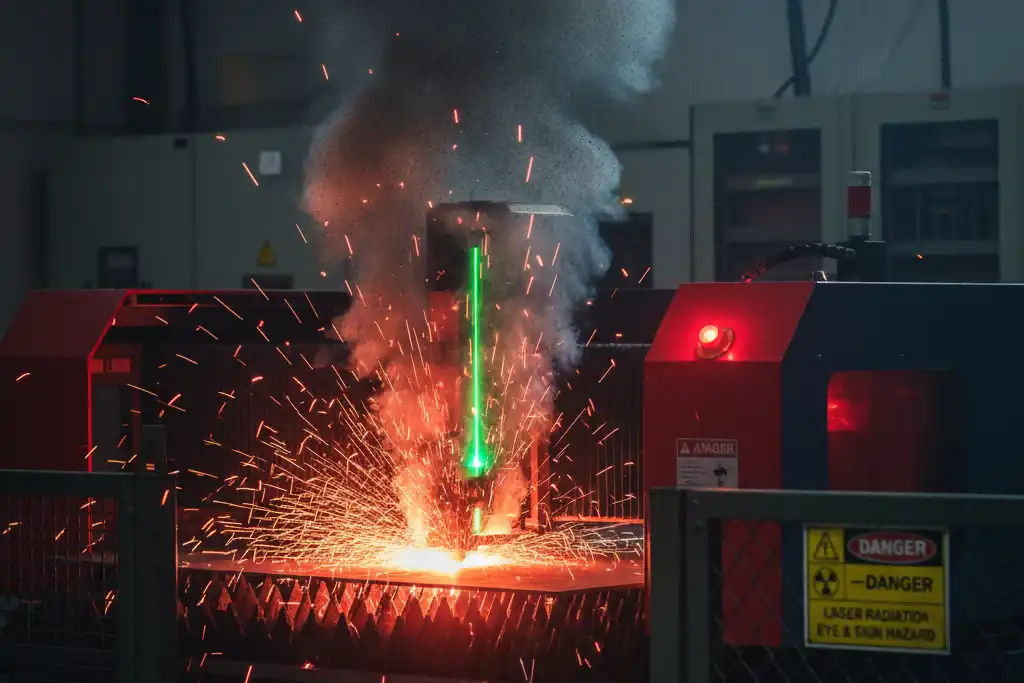

Is Laser Cutting Machine Radiation Dangerous?

Immediate Risks

There are real dangers when using laser cutting machines. Laser cutting machine radiation can hurt you fast if you do not stay safe. The strong beam can burn your skin. If you touch the beam, you might get bad burns. Your eyes are in danger too. Even a quick look at the beam can hurt your eyes. You could get blurry vision, red eyes, or itchy eyes. Sometimes, you do not feel pain right away, but damage still happens.

Here are some injuries people often get:

- Skin burns from touching the laser beam

- Eye injuries like hurting your retina or cornea

- Breathing problems from breathing in bad fumes

- Skin rashes or sores from bright light

- Headaches, feeling dizzy, or feeling sick from breathing in bad air

Tip: Always wear eye protection and never look at the beam. Make sure your room has fresh air so you do not breathe in fumes.

Common Myths

Some people believe things about laser cutting machine radiation that are not true. These wrong ideas can make you less safe. Let’s talk about some of these myths:

| Myth | Clarification |

|---|---|

| If you can’t see the beam, it can’t hurt you. | Invisible infrared radiation can hurt your eyes even if you do not see it. |

| Class 1 equipment is completely safe—no protection needed. | You must use the machine the right way and keep it working well. Skipping safety steps can be risky. |

| Reflected light is too weak to be dangerous. | Light bouncing off things can still be strong and hurt your eyes, so you need eye protection. |

Some people think laser cutting machine radiation is like nuclear radiation. That is not true. They are not the same. Not all laser radiation is bad for you. The risk depends on how strong the laser is and how long you are near it. You can get hurt from light that bounces or spreads, not just from the main beam. Bad fumes can form when cutting some materials, and these can make it hard to breathe.

Who Is at Risk

You might wonder who can get hurt by laser cutting machine radiation. Anyone near these machines can be at risk. If you already have health problems, your risk is higher. The kind of material you cut matters too. Some things make more bad fumes. The longer you are near the machine, the more likely you are to get hurt.

- People who use laser cutting machines every day

- Workers who fix or clean the machines

- People with asthma or breathing problems

- Workers who breathe in bad fumes or dust

- Anyone not wearing the right safety gear

Note: You can stay safer by following safety rules, wearing safety gear, and keeping your work area clean.

Laser Cutting Machine Radiation Explained

When you use a laser cutting machine, you work with a special kind of light called laser radiation. This light is not like the light from a lamp or the sun. It is much stronger and more focused. You need to know what kinds of radiation come from these machines. You should also learn how they are made to stay safe.

Types of Radiation

Laser cutting machines give off different kinds of radiation. You might not see all of them, but they can still hurt you.

Infrared and Ultraviolet

Laser cutting machines make optical radiation. This means they create strong light from infrared to ultraviolet.

- Infrared (IR): You cannot see infrared light. You can feel its heat. It can burn your skin or eyes if you get too close.

- Ultraviolet (UV): You cannot see ultraviolet light. It can cause skin burns or rashes. If you are exposed for a long time, it can even cause skin cancer. UV light can also hurt your eyes and cause lasting damage.

- Visible Light: Some lasers use visible light. You can see this light. Even visible beams can hurt your eyes.

Tip: Treat invisible beams with care. Invisible radiation can hurt you even if you do not see it.

Non-Ionizing vs. Ionizing

Most laser cutting machine radiation is non-ionizing. This means it does not have enough energy to change your cells or cause cancer like X-rays. Non-ionizing radiation includes infrared, ultraviolet, and visible light. Sometimes, a laser cutting machine can make a little ionizing radiation, like X-rays. This only happens at very high power.

- Non-Ionizing Radiation: Most machines use this type. It can still burn your skin or eyes. It does not change your DNA.

- Ionizing Radiation: This is rare in laser cutting machines. It can happen if the machine uses very high energy. Most people will not face this risk.

Note: Most laser cutting machine radiation is non-ionizing and usually safe. You can still get hurt if you do not use the right protection.

How Radiation Is Generated

You might wonder how a laser cutting machine makes such a strong beam. The word “LASER” means Light Amplification by Stimulated Emission of Radiation. The machine creates light in a special way.

Inside the machine, a process called stimulated emission happens. Here is how it works:

- The machine excites atoms inside a special material.

- When a photon hits one of these excited atoms, the atom releases another photon.

- Now there are two photons that are the same.

- Mirrors bounce these photons back and forth. This makes more and more photons.

- When enough photons build up, they shoot out as a strong, focused beam.

The machine focuses this beam through a nozzle. Sometimes, gases like oxygen or nitrogen help make the cut cleaner. The focused beam gets very hot. It can melt or vaporize metal, wood, or plastic along the cutting line.

Alert: The laser beam can burn your skin or eyes in seconds. Always wear safety glasses and never look at the beam.

Laser cutting machine radiation is powerful because it is so focused. The wavelength of the beam decides what kind of risk you face. For example, UV light can burn your skin. Infrared can burn your eyes. You need to use the right safety gear and follow all safety signs to protect yourself.

Health Risks

Eye Damage

Your eyes are very sensitive to laser light. Laser cutting machine radiation can hurt your eyes if you do not protect them.

Retinal Injuries

The retina is at the back of your eye. It helps you see things clearly. A laser beam can focus on the retina and cause harm. You might not feel pain right away, but the damage can be bad.

- Cataracts and burns can happen with wavelengths below 400 nm or above 1400 nm.

- Retinal burns happen most with wavelengths between 400-1400 nm. These burns can heat the retina and make you lose vision.

- The laser can heat up the tissue and cause burns.

- Chemical damage can change how the tissue works.

- Photoacoustic damage can make shockwaves that tear the tissue.

You can get hurt from the main beam, but also from light that bounces off shiny things or scattered light if the power is high.

Tip: Always wear laser safety glasses for your machine’s wavelength. Never look at the laser beam or any reflections.

Here are some safety steps you should follow:

| Safety Recommendation | Description |

|---|---|

| Avoid direct exposure | Never look into any part of the laser assembly. |

| Keep bay door closed | Make sure the laser cutter bay door is closed when it is on. |

| Use appropriate PPE | Wear laser safety glasses for your laser’s wavelength. |

Corneal Burns

The cornea covers the front of your eye. Laser beams can burn the cornea if you do not use protection. You might feel pain, redness, or see blurry spots. Burns can happen fast, so you need to be careful.

Skin Exposure

Burns and Irritation

Your skin can get hurt by laser beams too. If you touch the beam or get too close, you might get burns or rashes. Ultraviolet light can burn your skin or even raise your risk of skin cancer. You may see redness, swelling, or blisters after being exposed.

Alert: Always wear protective clothes and gloves when working near the laser.

Air Quality Concerns

Indoor Pollution

Laser cutting can put many pollutants in the air. These include gases, chemical vapors, and tiny pieces like microplastics and nanoparticles. Bad airflow can make these build up in your workspace.

| Pollutant Type | Description |

|---|---|

| Particulate Matter | Dust, fumes, or smoke from the cutting process. |

| Volatile Organic Compounds (VOCs) | Gases from materials, especially plastics, that lower indoor air quality. |

| Odors | Strong smells from cutting some materials that can bother you. |

Inhalation Risks

Breathing in these pollutants can give you headaches, dizziness, or make it hard to breathe. If you have asthma or allergies, you might feel worse. Always make sure your workspace has good airflow. Use fans or air filters to keep the air clean.

Note: You can protect yourself by wearing a mask and making sure your work area has good ventilation.

Laser Classifications

Understanding laser classifications helps you know how dangerous a laser cutting machine can be. Each class tells you what kind of risks you face and what safety steps you need to take.

Hazard Classes

Laser cutting machines fall into different hazard classes. These classes show how much risk the laser beam brings to your eyes and skin. You can use the table below to see what each class means:

| Class | Description |

|---|---|

| Class 1 | Safe and cannot cause harm. You do not need special controls. |

| Class 1C | Used for skin treatments. The design keeps your eyes safe, but your skin can get exposed. |

| Class 1M | Safe in normal use. If you use magnifying tools, it can become dangerous. |

| Class 2 | Uses visible light. Usually safe for short accidental exposure. Eye protection is still a good idea. |

| Class 2M | Like Class 2, but dangerous if you use magnifying tools. |

| Class 3R | Can be risky in some cases. The chance of injury is low, but you should still be careful. Not a fire hazard. |

| Class 3B | More dangerous if you look at the beam. Not likely to start fires or make bad air. |

| Class 4 | Most dangerous. Can hurt your eyes and skin. Can start fires and make harmful fumes. |

Tip: Always check the class of your laser machine before you use it. The higher the class, the more careful you need to be.

Class 4 Lasers

Class 4 lasers are the most powerful and hazardous. You find these in many industrial laser cutting machines. They can cause serious injuries to your eyes and skin. Even a quick flash or a reflection can hurt you. These lasers can also start fires and create dangerous fumes.

| Class | Hazard Level | Risks | Safety Measures |

|---|---|---|---|

| Class 4 | Maximum hazard | Eye, skin, fire | Laser safety glasses, flame-resistant clothing, gloves, face shields, respirators |

You should know these facts about Class 4 lasers:

- They can injure your eyes and skin with direct or reflected beams.

- They can cause burns even if you do not look straight at the beam.

- They can start fires if the beam hits flammable materials.

- You must use strong safety gear and follow strict rules.

Alert: Never use a Class 4 laser without proper training and safety equipment. Always keep the area clear of anything that can catch fire.

Safety Labels

Laser cutting machines must have clear safety labels. These labels help you know the risks and how to stay safe. You can find different types of labels on the machine:

| Label Type | Requirements |

|---|---|

| Classification Labels | Show the laser class, a warning word like “Danger,” a hazard statement, and the safety standard. |

| Product Information Labels | List the maker’s name, model number, date made, and the highest power the laser can reach. |

| Protective Housing Labels | Placed on panels that cover parts with dangerous radiation. |

| Interlocked Housing Labels | Found on panels that open to areas with dangerous radiation when unlocked. |

You must follow rules from groups like CDRH and IEC. These groups set the standards for what goes on each label. The labels use special words, symbols, and colors to warn you about the dangers.

- Labels must match the laser’s class and follow the right format.

- You should always read the labels before using the machine.

- Labels help you know when to wear safety gear and when to stay away.

Note: If you see a label with “Danger” or “Warning,” take it seriously. These labels protect you from harm.

Protective Measures

You need to be careful around laser cutting machines. Using the right protection helps you stay safe. Wear safety gear, follow rules, and keep learning about safety.

Personal Protective Equipment

Wear safety gear every time you use a laser cutter. PPE helps protect you from burns and eye injuries. It also keeps you safe from bad fumes.

Laser Safety Glasses

Laser safety glasses keep your eyes safe from strong beams. Regular glasses do not block laser light. Only special glasses work for fiber lasers. These glasses stop eye injuries, even if you are close to the beam. Groups like OSHA and ANSI say you must wear these glasses. Fiber lasers can hurt your eyes, even if you do not look at the beam. Always check that your glasses match the laser’s wavelength.

Tip: Always wear laser safety glasses. Even a quick flash can hurt your eyes forever.

Protective Clothing

Cover your skin to stop burns and rashes. Wear coveralls, head covers, and gloves. Face shields and masks give extra protection. This is important when cutting things that make dust or fumes. Protective clothing keeps your skin safe from sparks and hot surfaces.

Here is a list of PPE you should use:

- Laser safety glasses

- Protective clothing like coveralls and gloves

- Head covers

- Face shields

- Respiratory masks

Safe Operating Protocols

You can stop most accidents by following safety steps. Keep a fire extinguisher nearby and know how to use it. Pick machines from good brands that care about safety. Check your machine often and keep it in good shape. Never leave the machine running alone. Use a fume extraction system to clean the air. Know which materials are safe to cut so you avoid bad fumes or fires.

Follow these best practices:

- Keep a fire extinguisher close and know fire safety rules.

- Learn basic first aid for burns and cuts.

- Report accidents or near-misses right away.

- Stick to a regular maintenance plan.

- Make sure everyone gets proper training.

Training and Awareness

Training teaches you how to use the machine safely. You need hands-on practice to build good habits. Good training shows you how to use PPE, follow safety steps, and handle emergencies. Laser Safety Certification proves you know the rules and helps your workplace stay safe. Training often lowers the chance of accidents. You also learn new safety tips and keep your skills sharp.

Note: Make safety training part of your job. The more you practice, the safer you are around laser cutting machine radiation.

Regulatory Standards

Laser cutting machines have to follow safety rules. These rules help keep everyone safe. There are three main safety areas. They are OSHA guidelines, ANSI standards, and workplace rules.

OSHA Guidelines

OSHA means Occupational Safety and Health Administration. OSHA makes rules to protect workers. You must follow these rules when using laser cutting machines. OSHA says you need to wear protective gear. This includes laser safety glasses and special clothes. You should keep fire extinguishers close by. Your work area should not have things that can catch fire.

OSHA wants you to use good ventilation. You need exhaust systems to get rid of dust and fumes. You must learn lockout/tagout steps for maintenance. This helps stop electrical shocks. OSHA expects you to get training about laser dangers and what to do in emergencies.

| OSHA Requirement | What You Must Do |

|---|---|

| Protective Equipment | Wear laser safety glasses and clothing |

| Fire Safety | Keep fire extinguishers close |

| Ventilation | Use exhaust systems for fumes |

| Electrical Safety | Use lockout/tagout during maintenance |

| Training | Learn about laser hazards and emergencies |

Tip: Always check your work area for safety before starting.

ANSI Standards

ANSI stands for American National Standards Institute. ANSI makes rules for laser safety. You must follow these rules to stay safe. ANSI says you need warning signs near laser machines. You should keep files with design and risk details.

ANSI wants machines to have safety features. These include interlocks and emergency stops. You should check your machine often to make sure it works. ANSI also says to wear protective gear and use fire safety tools like smoke detectors.

| ANSI Standard | What You Must Do |

|---|---|

| Warning Signs | Post signs in laser work areas |

| Technical Documentation | Keep files with design and risk details |

| Safety Features | Use interlocks and emergency stops |

| Protective Gear | Wear goggles and laser-rated clothing |

| Fire Safety | Install smoke detectors and extinguishers |

Note: ANSI rules help you find dangers and stop accidents.

Workplace Compliance

You must follow workplace rules to stay safe. Your boss must give you training about laser dangers and emergencies. You should see warning signs in your work area. You need exhaust systems to keep the air clean. Fire extinguishers and safe work areas help stop fires.

You must wear protective gear like goggles and special clothes. Your workplace should check machines often to make sure they are safe. You need to follow lockout/tagout steps for maintenance. Your boss must keep files with design and safety details.

- Training about laser dangers and emergencies

- Warning signs in laser work areas

- Exhaust systems for dust and fumes

- Fire extinguishers and safe work areas

- Lockout/tagout steps for electrical safety

- Risk checks and safety files

- Machines with interlocks and emergency stops

- Regular checks for machine safety

- Operators must wear goggles and special clothes

Alert: Following these rules keeps you safe and helps your workplace follow the law.

Laser cutting machine radiation can hurt you. It can burn your skin. It can damage your eyes. It can make it hard to breathe. You can stay safe by wearing protective gear. You should always follow safety rules. Many machines have safety features to help you:

| Safety Feature | Description |

|---|---|

| Automatic Protective Doors | These doors keep you safe from the laser beam. |

| Dust and Smoke Filtration Modules | These filters clean the air by removing harmful particles. |

You should follow standards like ANSI Z136.1 and EN 60825-1. If you use the right safety steps, you can work safely. You should keep learning about laser safety. This helps you protect yourself and others.

FAQ

What should you do if laser radiation hits your skin?

Move away from the beam right away. Check your skin for burns or redness. Wash the area with cool water. Tell your supervisor. Seek medical help if you see blisters or feel pain.

Can you use regular sunglasses for eye protection?

No, regular sunglasses do not block laser beams. Only laser safety glasses made for your machine’s wavelength protect your eyes. Always check the label before use.

Is it safe to watch a laser cutting machine from behind glass?

Some glass blocks laser beams, but not all. You must use special laser safety windows. Always check if the glass is rated for your laser’s wavelength.

What materials create the most harmful fumes?

Plastics like PVC and some painted metals make dangerous fumes. These fumes can hurt your lungs. Always use good ventilation and wear a mask when cutting these materials.

How often should you check your safety equipment?

Check your safety gear before every use. Look for cracks or damage. Replace broken or old equipment right away. Safe gear keeps you protected.

Can laser radiation cause cancer?

Most laser cutting machines use non-ionizing radiation. This type does not cause cancer. Ultraviolet light can raise skin cancer risk with long exposure. Always wear protective clothing.

What should you do if you see a warning label on a laser machine?

Read the label carefully. Follow all safety steps listed. Wear the right protective gear. Never ignore warning signs. They help keep you safe.

Do you need training to use a laser cutting machine?

Yes, you need training. Training teaches you how to use the machine safely. You learn about risks, safety gear, and emergency steps. Trained users have fewer accidents.

See also

How to Match Laser Cleaning Power Levels to Your Needs

How to Protect Yourself When Operating a Laser Cleaning Machine

Top 10 Industries for Laser Cleaning Machine Applications

How to choose a laser cleaning machine with appropriate power